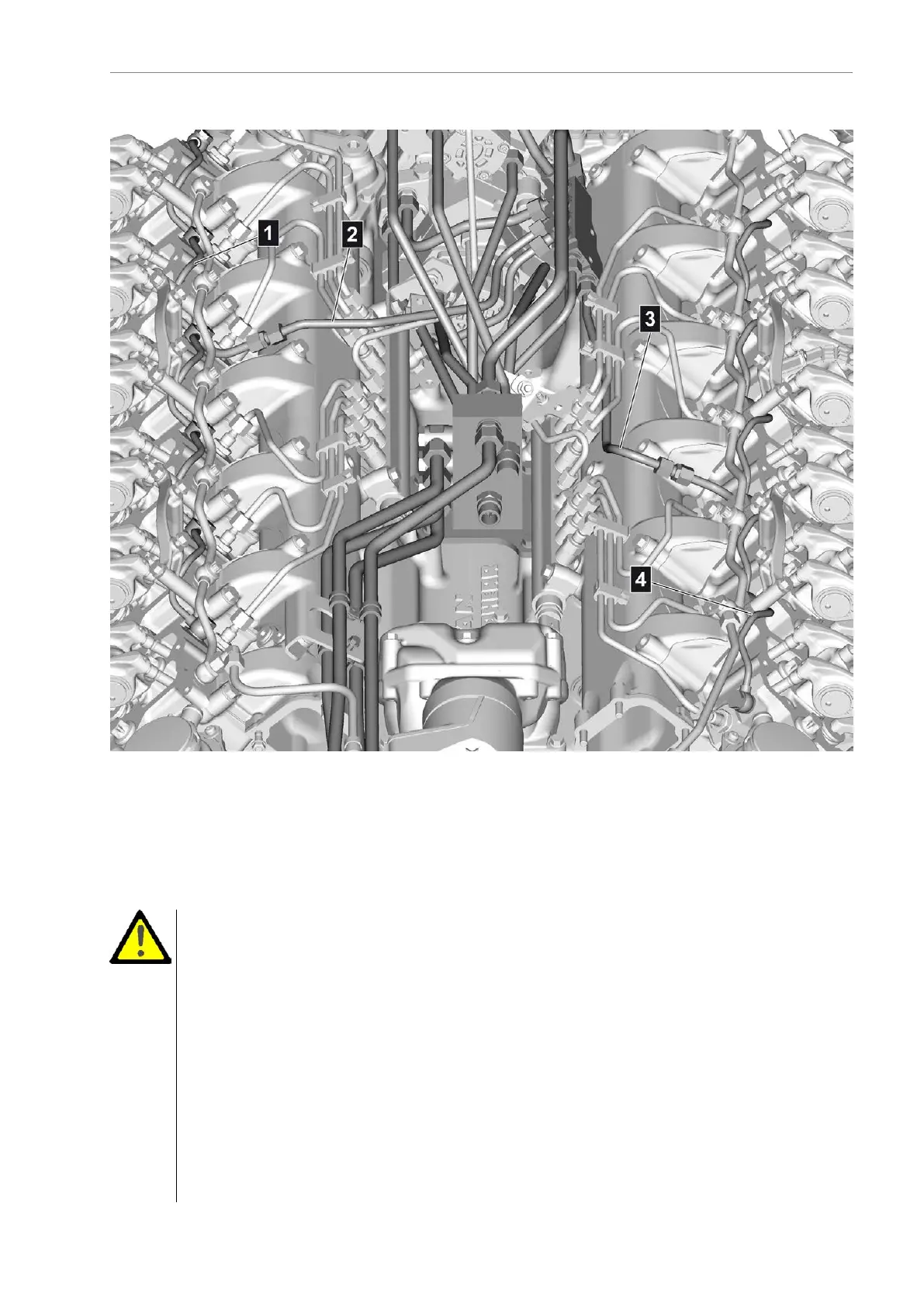

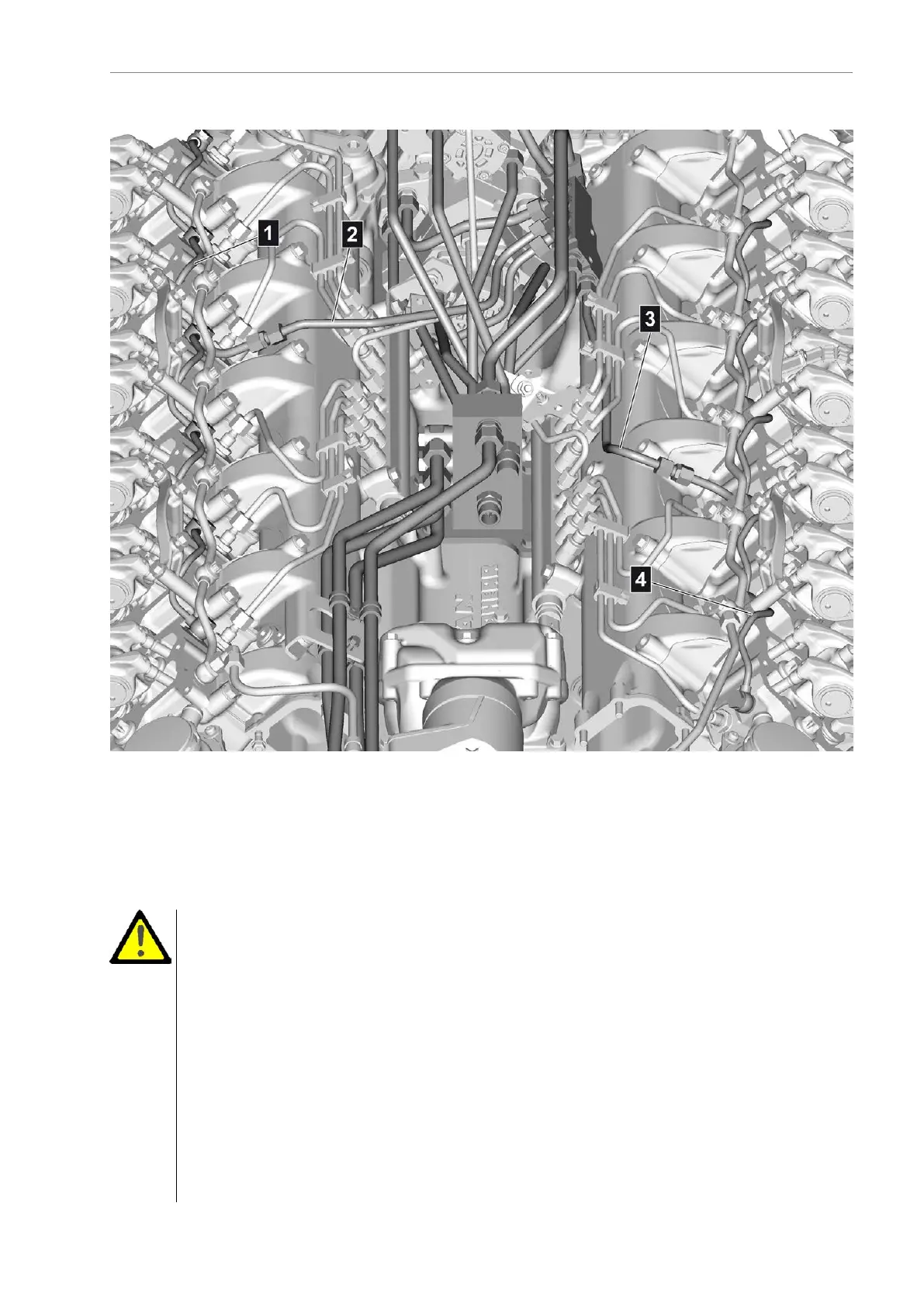

COMMONRAILSYSTEM

Checkingtheinjectorseat,railandleakageoillinesforleaks

(1)Leakageoilline

(2)Fuelline,leakageoilline-collector

(3)Fuelline,leakageoilline-collector

(4)Leakageoilline

Technicaldata

Pressurisation,driptest.........................................................................................................3.0-3.5bar

Pressuredrop..........................................................................................................0.1barin10minutes

Importantinformation

WARNING

Thecommon-railsystemcanbedamaged

•Allworkoncomponentsofthecommon-railsystemmustbeperformedbyspeciallytrained

personnelonly

•Theenginemustbestationaryforatleast5minutesbeforecommencingworkinordertoenable

depressurisationintherail,ordepressurisationmustbecheckedbymeansofMAN-cats

®

(desiredvalue0)

•Ensureabsolutecleanlinessinallareaswhencarryingoutallwork

•Beforeworkingonthecleansideofthefuelsystem,cleantheengineandtheenginecompartment

(e.g.steamcleaner).Thefuelsystemmustbesealedduringthisprocess.

•Avoidanymoisturewhatsoever

•Alwaysreplacerailconnectionsoncetheyhavebeenundone

•Donotreuseplugsforhigh-pressurelines,therailorinjectors,eveniftheyhaveonlybeenused

once

•Followthesequencedescribedwhentighteninginjectors,high-pressurelines,therailandrail

connections

AE63stedition125

Loading...

Loading...