Manitowoc Published 12-05-17, Control # 032-23 3-41

18000 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

Load Drum Operation

See Figure 3-10 for drum identification.

See Figure 3-21

for the following description of operation.

.

1. Select and confirm desired crane mode.

2. Depending on mode selected, load drums are controlled

by handles B, C or D. See handle display light to

determine what load drum is controlled by what handle.

3. Turn off drum park for drum to be operated.

4. Increase engine speed to desired RPM with hand

throttle. Depress foot throttle to momentarily increase

engine speed when more power is required.

5. Pull load control handle B, C or D (Drum 1, Drum 2, or

Drum 3) BACK from off to RAISE load or push load

control handle FORWARD from off to LOWER load.

NOTE: Excessive speed will cause drum spooling

backlash with reduced rope tension as a result of:

• Boom and luffing jib at high angles

• Wind loading from front

• Light load blocks

6. As load nears desired position, slowly move load control

handle toward off to slow down load. Then release

handle to off to stop load and hold it in position (drum

park brake will apply).

WARNING

Falling Load Hazard!

Prevent load on unused drums from falling. Turn on drum

park for drums not in use.

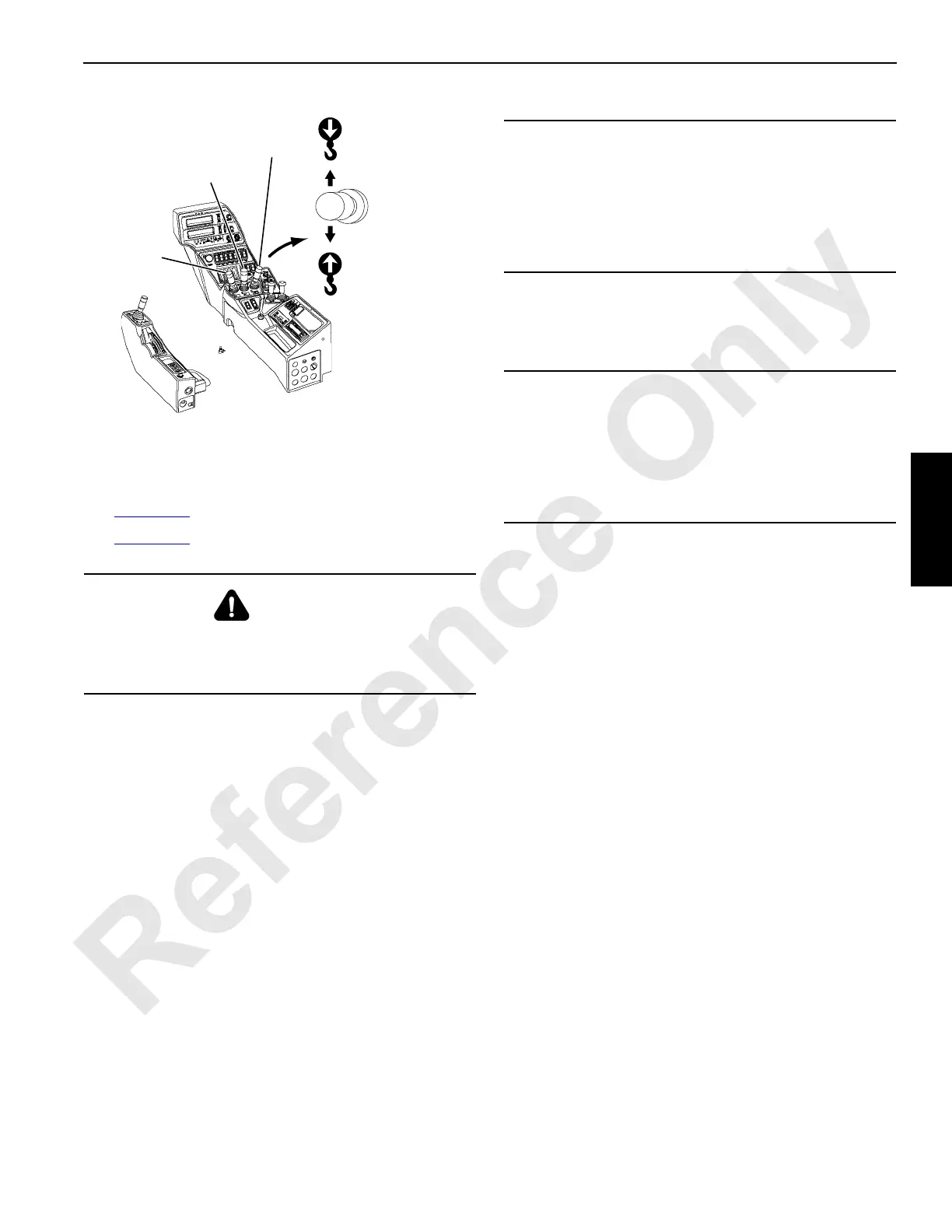

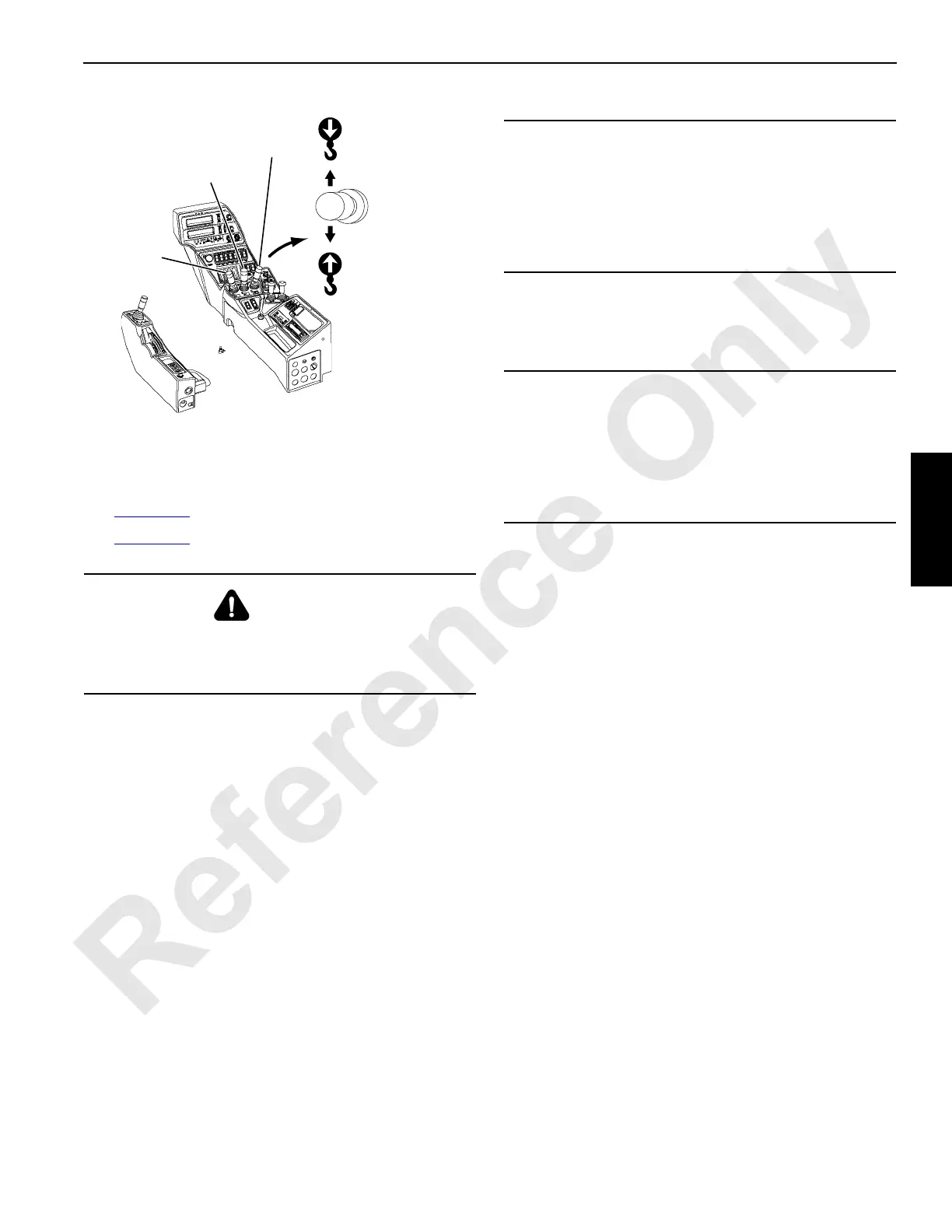

FIGURE 3-21

Lower

Load

Typical All

Load Drums

OFF

Raise

Load

Handle D

Handle B

Handle C

3-119

3-104a

CAUTION

Boom Damage!

Do not turn on load drum park while raising or lowering

load. Brake will bring load to an abrupt stop. This action

could cause shock load damage to boom and load line.

Bring load to a smooth stop with control handle and then

turn on drum park.

CAUTION

Drum Spooling Backlash!

Lowering/hoisting with reduced rope tension (slack) will

cause drum spooling backlash, improper spooling of wire

rope on the drum, and possible pull through. The crane

operator shall maintain proper rope tension while

lowering/hoisting load blocks, booms, and luffing jibs.

Loading...

Loading...