SET-UP AND INSTALLATION 18000 OPERATOR MANUAL

4-26

Published 12-05-17, Control # 032-23

Install Cab Rear Platform (Current

Production)

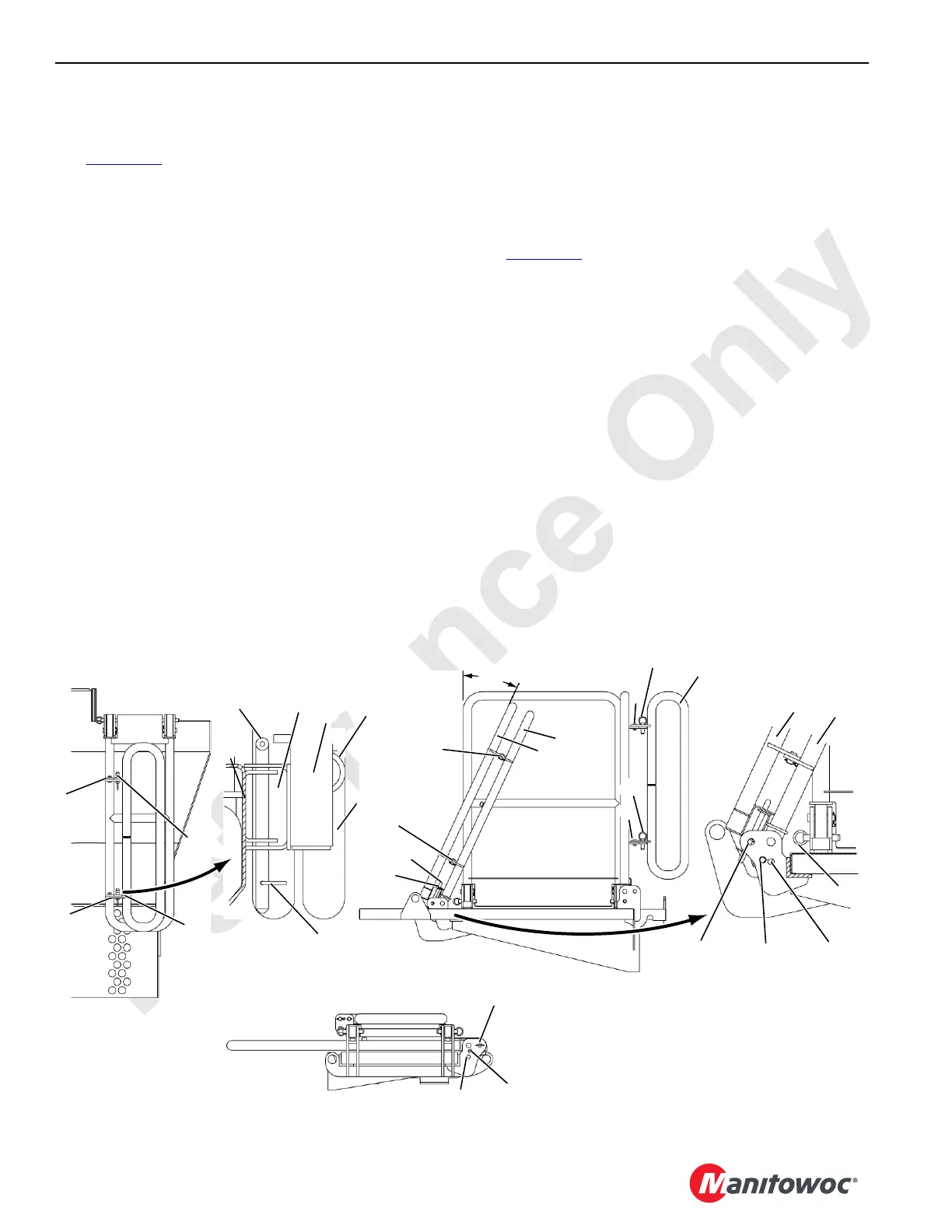

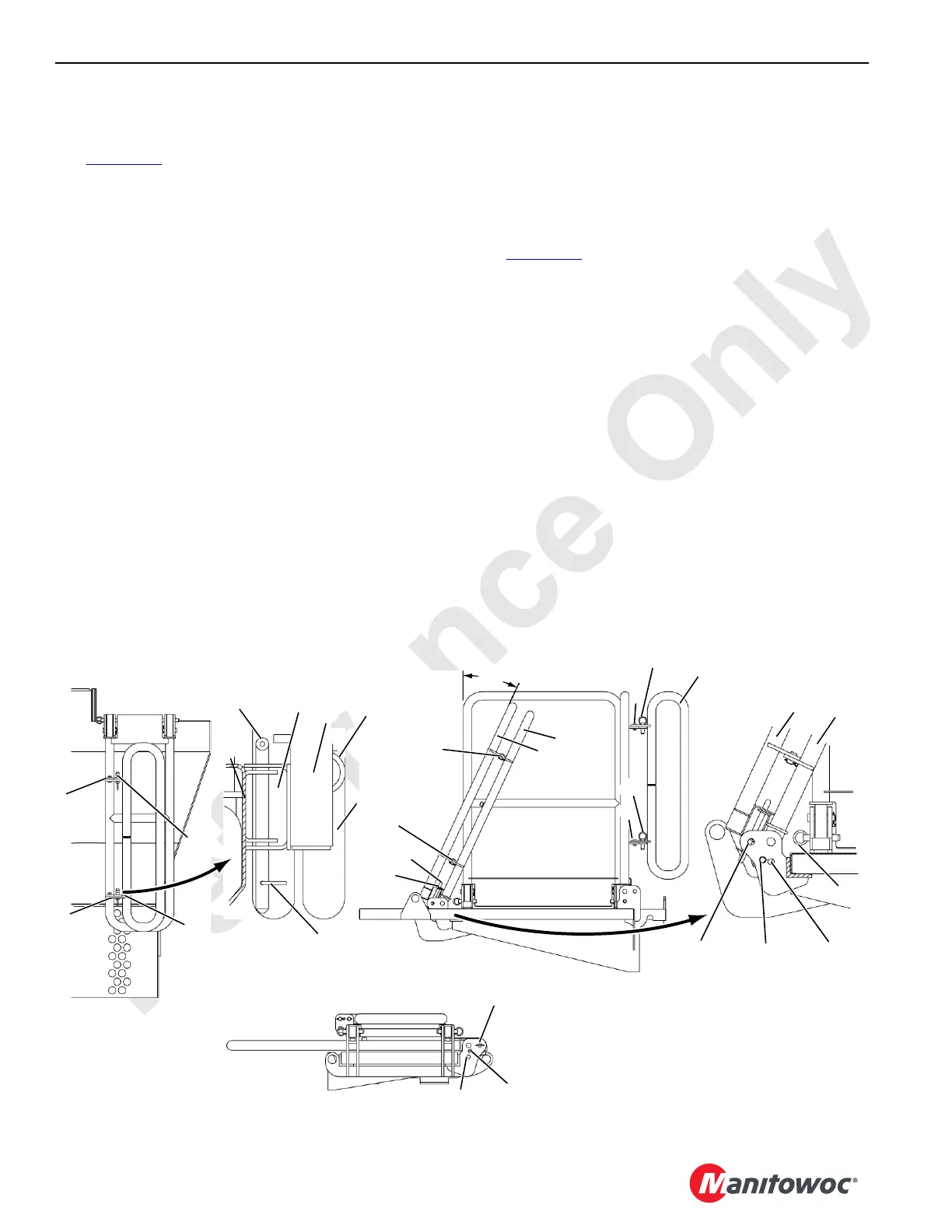

See Figure 4-17 for the following procedure.

NOTE Fork pockets are included in the platform floor for

handling by a fork truck.

1. Remove quick release pins (4) from short rear handrail

assembly (13 and 14, View A) to allow movement of

assembly about pins (9, View B).

2. Raise short rear handrail assembly (13 and 14, Views C

and D) into working position and secure by inserting

quick release pins (4, two places, View D) into working

position holes in platform weldment (5).

3. Remove quick release pins (4) from left rear (15, View A)

and long rear (16 and 17) handrails.

4. Raise left rear handrail section (15, Views A and C) into

working position and secure by inserting quick release

pins (4, View D) into working position holes in platform

weldment (5).

5. Raise long rear handrail assembly (16 and 17, Views A,

C and H) into lifting position and secure by inserting

quick release pins (4, View A) into lifting position holes

in weldment (View I).

6. Lift cab rear platform (1) into position using chain slings

from assist crane connected to four lifting holes (Views A

and C). Hooks (18, View E) in platform catwalk should

fully engage fixed pins (19) on rear of cab.

7. Remove chain slings from lifting holes in platform

assembly.

8. Level the platform’s catwalk as required after installation

with two leveling bolts (21).

Move Platforms into Working Positions

(Current Production)

See Figure 4-17 for the following procedure.

1. Remove quick release pins (10, View H) from weldments

to allow movement of short rear handrail wing (14)

around pins (6).

2. Rotate short rear handrail wing (14) 90° into working

position (View C) and secure by inserting quick release

pins into working position holes in weldments (View J).

3. Remove quick release pins (4, View I) from long rear

handrail assembly (16 and 17), carefully rotate

assembly into the working position and secure by

inserting same quick release pins into working position

holes.

4. Rotate rear handrail wing (17, View C) 90° about pins (9)

into working position and secure by inserting round bar

(11, Views G and H) into holes in weldments

5. Remove quick release pins (4, Figure 4-16, View H)

from long handrail (10), rotate to working position and

secure by inserting quick release pins (4) into working

position holes in weldment (5).

View F

View G (Detail)

View H

View I

25°

4

4

6

6

11

10

6

11

6

9

9

Working

Lifting

Shipping

10

10

FIGURE 4-17 continued

13

17

14

16

View J

Working

Lifting

Shipping

4

16

17

16

17

14

6

6

7

7

7

7

Loading...

Loading...