Maintenance overview

5.4 Measures required for winch monitoring

09.03.2018

Maintenance manual 3 302 746 en 5 - 23

GMK5200-1

Determining

the operating

conditions

(load spectrum)

The truck crane's load spectrum is divided into groups (see also ISO 4301/1,

FEM 1.001):

H

When determining the load spectrum, the existing rope pull is used as the

standard, i.e. under certain circumstances, the truck crane can be support-

ing a small load, whereby the winch is actually supporting a heavy load, e.g.

due to insufficient reeving. Therefore, the following graphic representation

of the load spectrum refers to the winch's rope pulls.

s

Load

spec-

trum

class

Definition Timing period proportions Factor of

the load

spectrum

Km =

Graphic representation

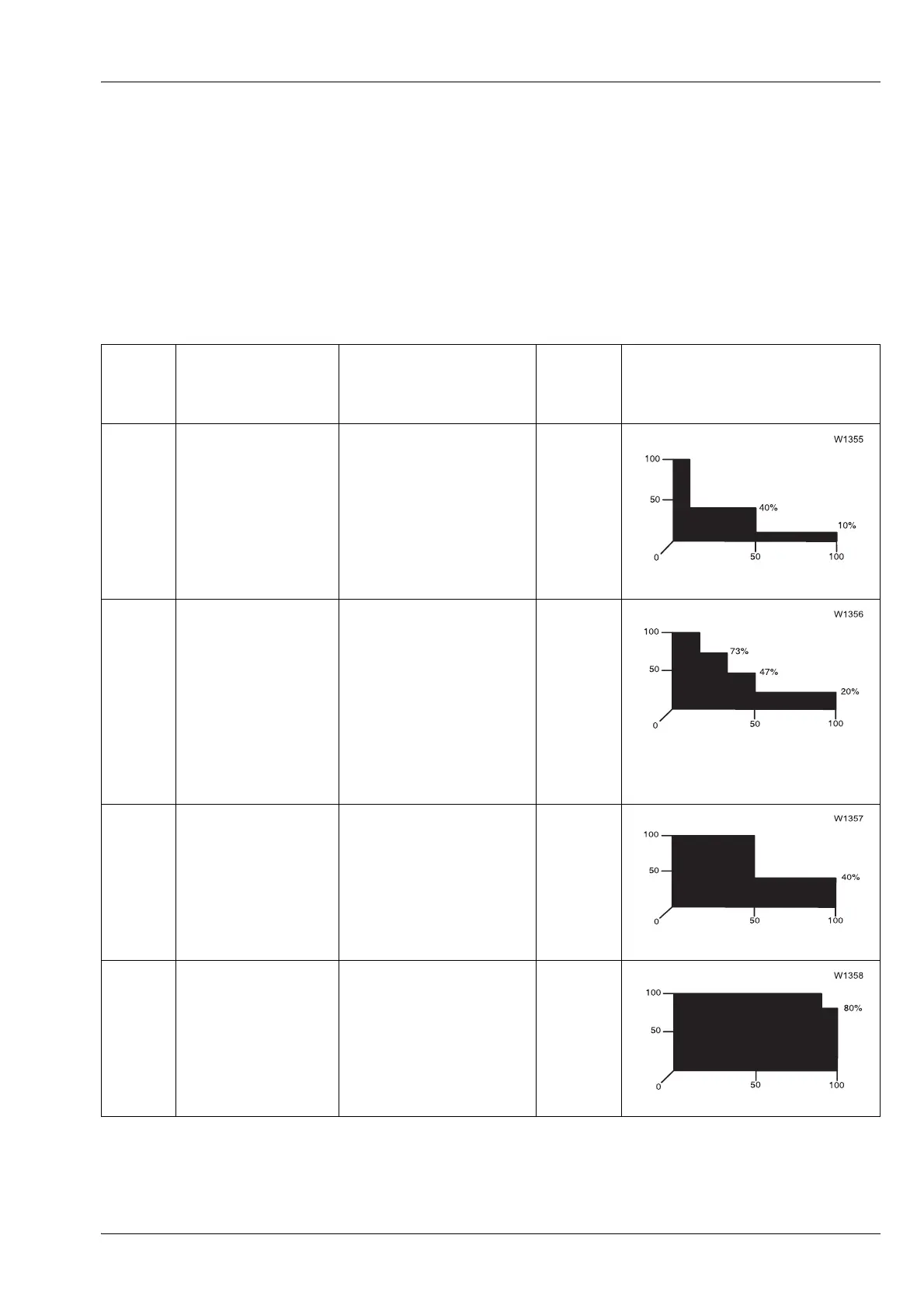

Light

Q 1

L 1

Power units or parts

thereof that are subject

to high stress in excep-

tional situations, but

which are generally sub-

ject to only low stress

10% of the timing period with

greatest load (dead load +

1/1 payload)

40% of the timing period with

dead load + 1/3 payload

50% of the timing period with

dead load only

0.125

Medium

Q 2

L 2

Power units or parts

thereof that are subject

to high stress quite fre-

quently, but which are

generally subject to only

low stress

1/6 of the timing period with

greatest load (dead load +

1/1 payload)

1/6 of the timing period with

dead load + 2/3 payload

1/6 of the timing period with

dead load + 1/3 payload

50% of the timing period with

dead load only

0.25

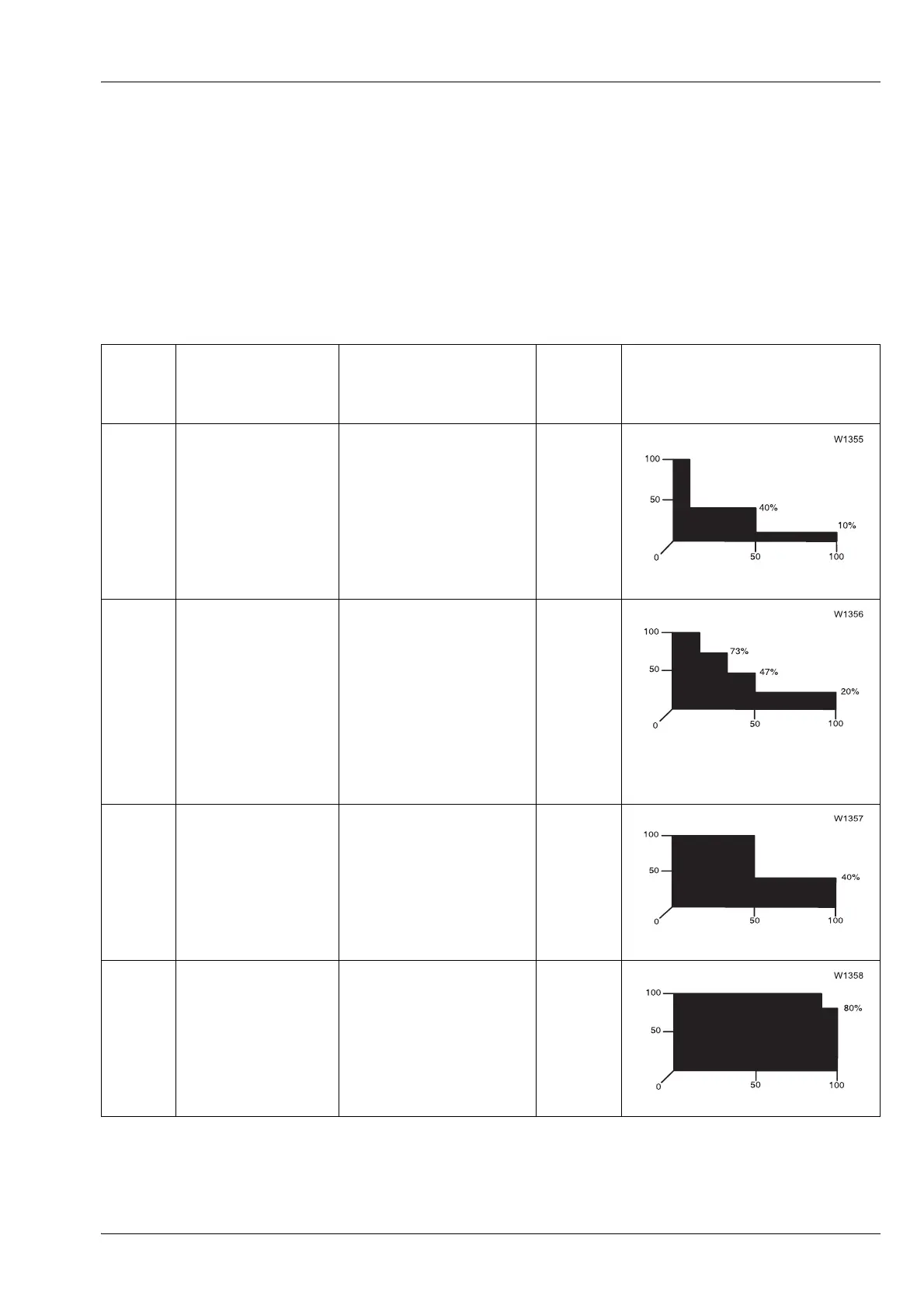

Heavy

Q 3

L 3

Power units or parts

thereof that are subject

to high stress frequently

and medium stress con-

tinuously

50% of the timing period with

greatest load (dead load +

1/1 payload)

50% of the timing period with

dead load only

0.5

Very

heavy

Q 4

L 4

Power units or parts

thereof that are regularly

subjected to the highest

stress from adjacent

stress sources

90% of the timing period with

greatest load (dead load +

1/1 payload)

10% of the timing period with

dead load only

1

Loading...

Loading...