Manitowoc Published 10-09-2020, Control # 259-06 5-33

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL HOISTS

Periodic Comprehensive Inspection

The comprehensive inspection must be done by a qualified

person. The inspection must include pulling all the rope off

the drum and carefully inspecting the entire length.

The inspection must include the following:

• All points listed under Daily Inspection on page 5-32

• Inspection of the rope diameter (see Reduction in the

Rope Diameter on page 5-34)

• Comprehensive examination for broken wires (see

Broken Rope Wires on page 5-34

)

• End connections. Check for broken wires or severely

corroded, cracked, bent, worn, or improperly applied

end connections

• Areas subjected to rapid deterioration are as follows:

- Sections in contact with the saddles, equalizer

sheaves, or other sheaves where the wire rope

travel is limited

- Sections of the wire rope at or near the terminal

ends where corroded or broken wires may protrude

• Inspection of the boom sheaves, hook block sheaves,

gantry/mast sheaves, boom extension/jib sheaves, jib

strut sheaves, and hoist drums for wear

NOTE: Damaged sheaves or hoist drums can accelerate

wear and cause rapid deterioration of the wire

rope.

Any damage of the wire rope found must be recorded and a

determination made as to whether continued use of the rope

is safe (refer to Replacement Criteria on page 5-34

).

Determining the Frequency of Inspection

Intervals for comprehensive inspections may vary from

machine to machine. The inspection interval must be

determined by a qualified person and must be based on such

factors as the following:

• Expected rope life as determined by experience on the

particular installation or similar installations

• Size, nature, and frequency of lifts

• Rope maintenance practices

• Severity of the environment, such as the following:

- Variation in the temperature

- Continuous excessive moisture levels

- Exposure to corrosive chemicals or vapors

- Subjecting the wire rope to abrasive material

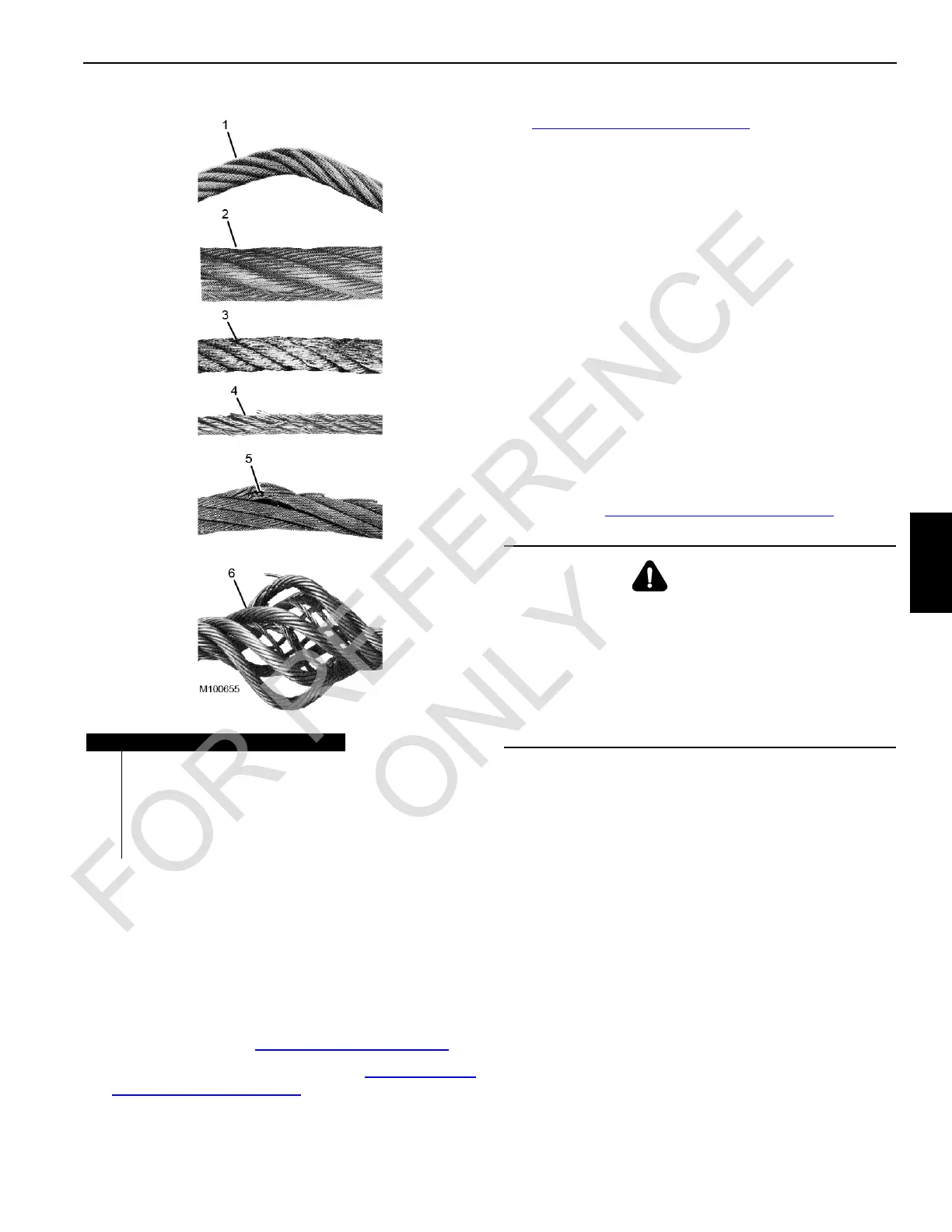

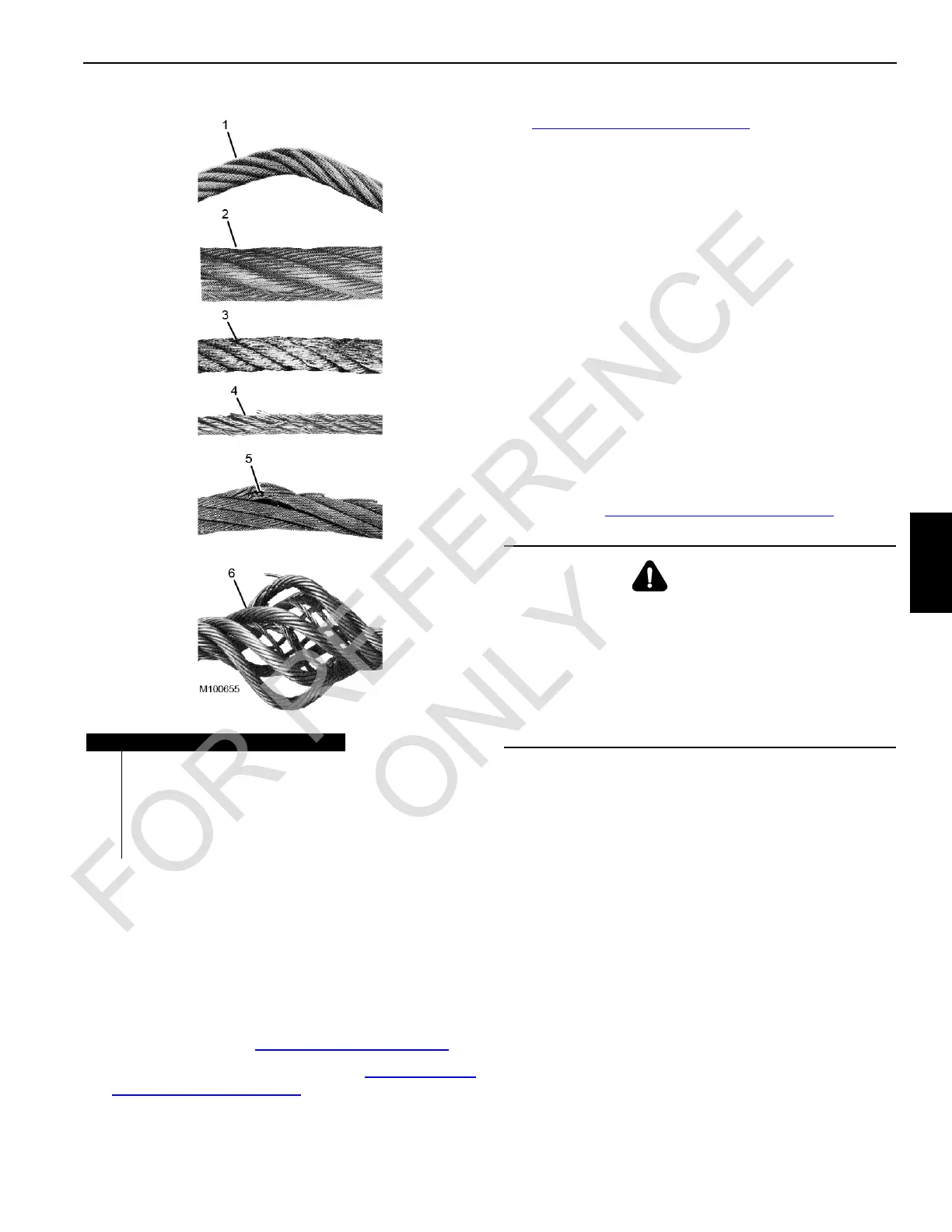

Item Description

1 Dog-Leg or Kink

2Drum Abrasion

3 Drum Crushing

4 Sheaves Too Small

5Corrosion

6 Bird Cage (sudden release of load)

FIGURE 5-21

WARNING

Falling Load Hazard!

All wire rope will eventually deteriorate to a point where it

is no longer usable.

• As a wire rope approaches the end of its useful life,

do inspections more frequently.

• A comprehensive inspection of each wire rope must

be performed at least once a year.

Loading...

Loading...