HOISTS MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL

5-18

Published 10-09-2020, Control # 259-06

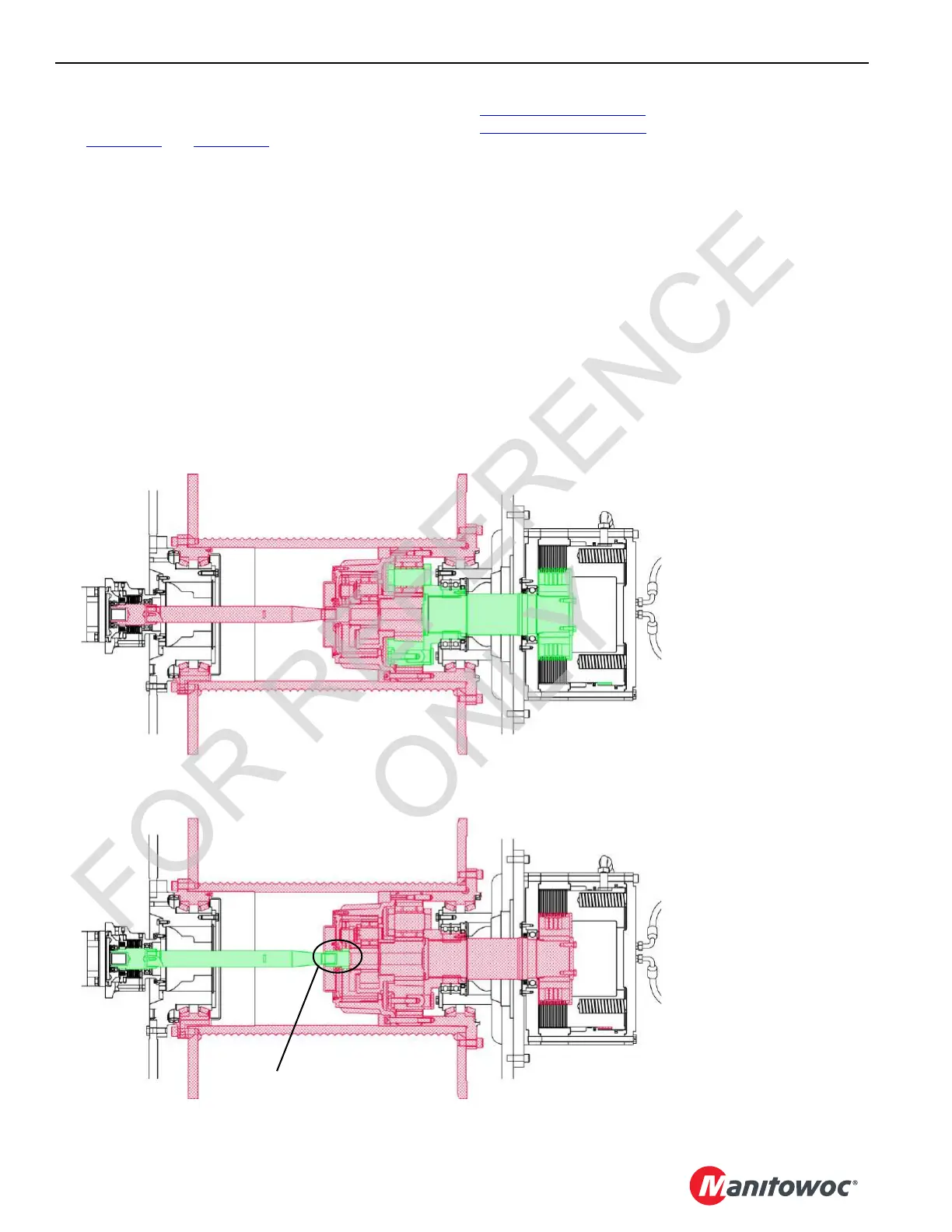

Free Fall System (Optional)

See Figure 5-10 and Figure 5-11.

Drum 1, Drum 2, or both drums can be equipped with the

free fall option. When FF is enabled, the large spring-

applied, hydraulically-released disc brake on the right end of

drum is used to control the lowering of a load. Raising a load

when free fall is enabled works the same as in normal

operation.

NOTE When the crane is not in free fall mode, depressing

the free fall brake pedal has no effect on hoist

operation.

The motor and the disc brake on the motor end of the drum

used on the free fall drum are the same as those used on the

non-free fall drum.

When equipped with free fall, the CCS determines whether

drum speed is taken from the motor speed sensor

(Figure 5-18 on page 5-25

) or from the free fall speed sensor

(Figure 5-19 on page 5-26

).

The speed sensor sends a signal to the rotation indicator

(thumper solenoid) in the control handle. The rotation

indicator pulsates with a varying frequency to indicate drum

rotational speed. The direction of rotation is also displayed

on the main display via an arrow on the corresponding drum

icon.

Cooling oil flow through the brake is continuous whether or

not the free fall mode is enabled. Cooling oil flow at 3.5 bar

(70 psi) is provided by the free fall cooling pump, which is

dedicated for this purpose.

Brake release pressure is provided by a the free fall pump

which is relief-valve limited to 66 bar (950 psi). The CCS

receives a position signal from the free fall brake pedal and

uses this information to proportionally adjust the brake

release pressure in order to allow the drum to free fall.

Drum Control Handle—Raise

Hoist Operates Normally

Drum Control Handle—Neutral

The load is controlled by the operator

using the clutch/brake pedal

Free fall brake is spring-engaged—

Brake shaft does not rotate, is

disconnected from drive gears.

Free fall brake can be

hydraulically released—

Brake shaft can rotate as the

clutch/brake is released. Brake

shaft is connected to drive gears.

Motor shaft disconnected from

drive gears

M100826

FIGURE 5-12

Loading...

Loading...