POWER TRAIN MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL

7-8

Published 10-09-2020, Control # 259-06

ENGINE MAINTENANCE

Refer to the Engine Manufacturer’s Manual supplied with the

crane for engine maintenance intervals and procedures.

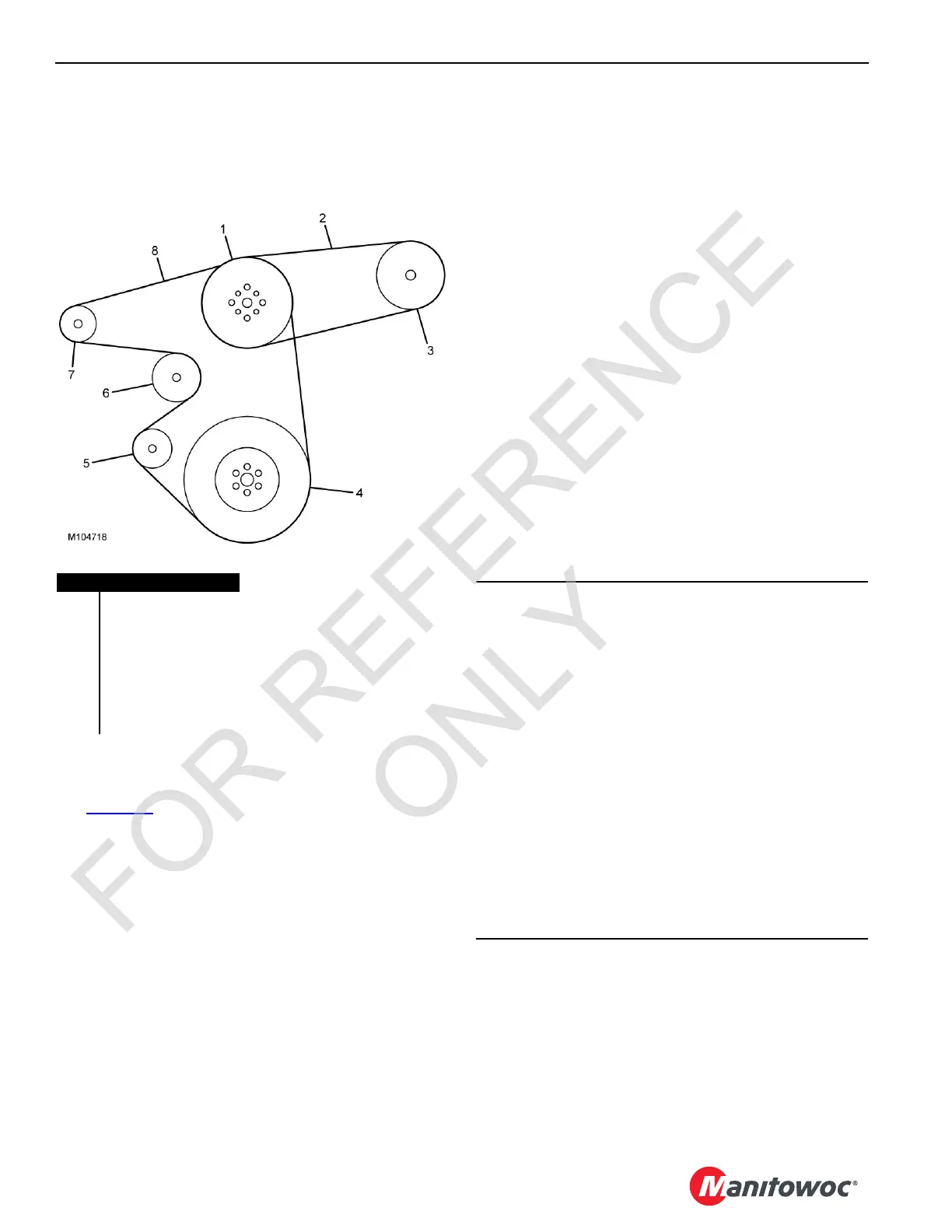

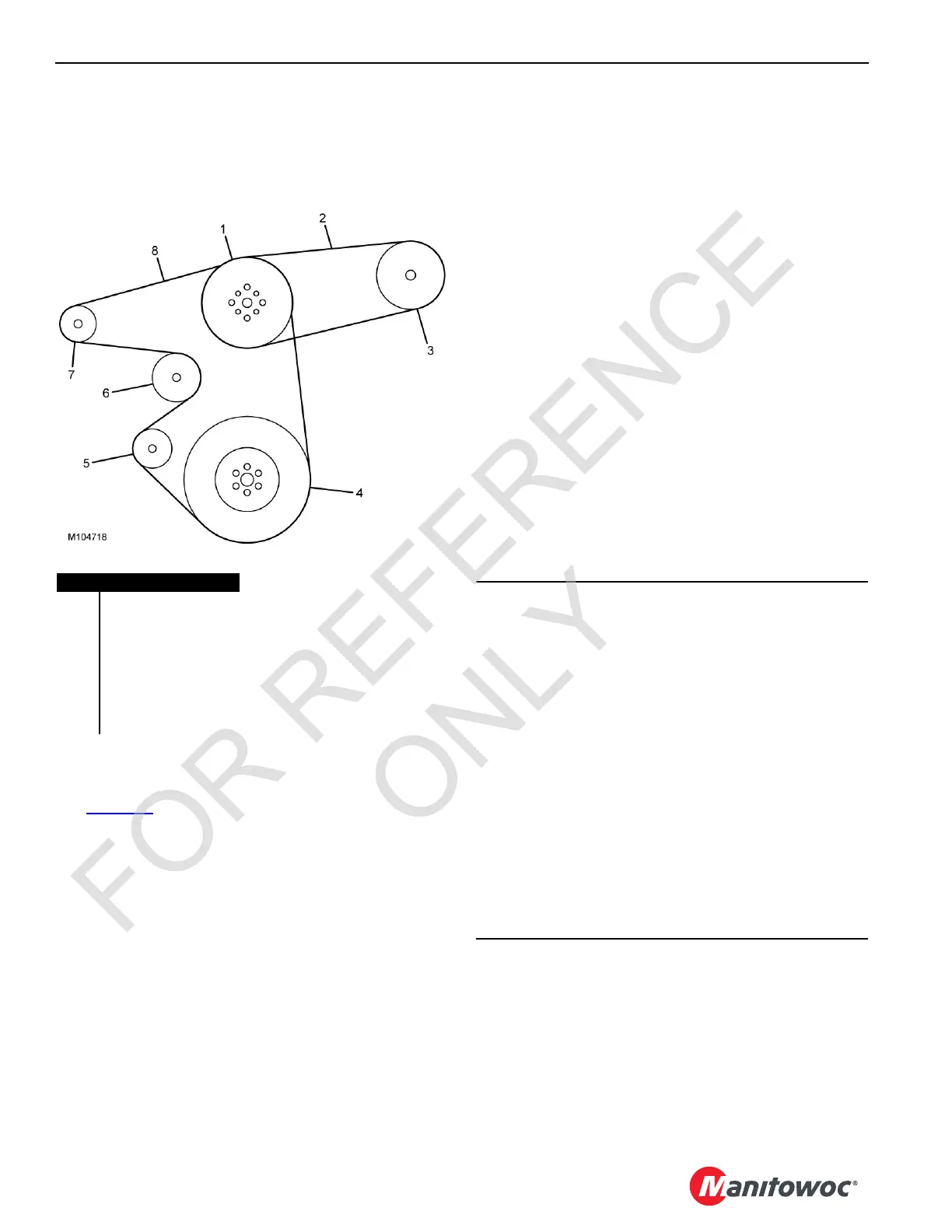

ENGINE BELT ROUTING

AIR CLEANER MAINTENANCE

See Figure 7-8 for the following procedure.

The air cleaner requires periodic maintenance due to the

following:

• Clogged air cleaner filters prevent adequate air flow to

the engine, causing poor starting and increased exhaust

emissions.

• An improperly installed or damaged air cleaner can

allow dirty air to be drawn directly into the engine.

Either condition can cause engine damage. To maintain

engine protection and air cleaner filter service life, inspect

the air cleaner at the following intervals.

Daily Inspection

Daily or Every 8 Hours of Engine Operation (whichever

occurs first)

Check the service indicator (1) with the engine running. The

indicator gives a visual indication when it is time to change

the air cleaner filters.

A yellow stem in the indicator window (1A) extends as the air

cleaner filters become plugged. Change the air cleaner filters

when the yellow stem reaches the red zone of the window.

The yellow stem remains locked in place when the engine is

stopped. The reset button (1B) on the top of the indicator can

be pressed at any time. When the engine is started, the

indicator stem returns to the proper reading.

Monthly Inspection

Monthly or Every 200 Hours of Engine Operation

(whichever occurs first)

• Inspect the rubber reducers, the reducing elbows, and

the tubing between the air cleaner and the engine for

cracks or other damage that might allow unfiltered air to

enter the engine. Replace worn or damaged parts.

• Check for loose clamps. Tighten as required.

• Check the air cleaner housing (2) for damage that may

allow unfiltered air to enter the engine. Replace the

housing if it is damaged.

• Inspect the cover (4). Make sure it securely in place.

Changing the Air Cleaner Filters

1. Lock out tag out the crane.

2. Un-clip and remove the cover (4).

3. Remove the primary filters (5) gently to avoid dislodging

dust from the filters.

There will be some initial resistance, similar to breaking

the seal on a jar. Using the handle (5A) on each filter,

Item Description

1Fan Pulley

2Belt 2

3 A/C Compressor

4 Harmonic Balancer

5 Tensioner

6 Water Pump

7 Alternator

8Belt 1

FIGURE 7-7

CAUTION

Avoid Engine Damage!

• Stop the engine before servicing the air cleaner.

Otherwise, unfiltered air will be drawn directly into the

engine. Never operate the engine without the air

cleaner or filters.

• Before servicing, clean the fittings, the mounting

hardware, and the area around the components to be

removed.

• Replace the secondary filter as quickly as possible to

prevent contaminants from entering the engine

intake.

• Do not attempt to clean and reuse old filters. Discard

them and install new filters. Cleaning filter elements

by impact or compressed air voids the warranty and

can degrade or damage the filter media, leading to

engine damage.

Loading...

Loading...