POWER TRAIN MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL

7-4

Published 10-09-2020, Control # 259-06

BATTERY MAINTENANCE

Quarterly or Every 500 Hours of Engine Operation

(whichever occurs first)

• Thoroughly clean the batteries with a baking soda/water

solution.

• Clean the posts and terminals. The posts can be lightly

coated with petroleum jelly to prevent corrosion.

•

Check the electrolyte levels. If required, add additional

electrolyte to bring all levels to the bottom of the vent

wells. DO NOT OVERFILL. If the batteries require

topping off while in service, add distilled water — DO

NOT ADD

ACID.

• Replace frayed, broken, or corroded cables.

• Replace the batteries if their containers are cracked or

worn to the point that they leak.

• Ensure there is tight contact between the clamp

terminals and battery posts.

• Make sure that the hold-downs are in good condition.

Replace any faulty parts.

• Make sure the hold-downs are tight enough to prevent

battery movement, but not so tight as to cause distortion.

• Make sure the battery retaining bars are installed.

• Makes sure the battery box cover is installed.

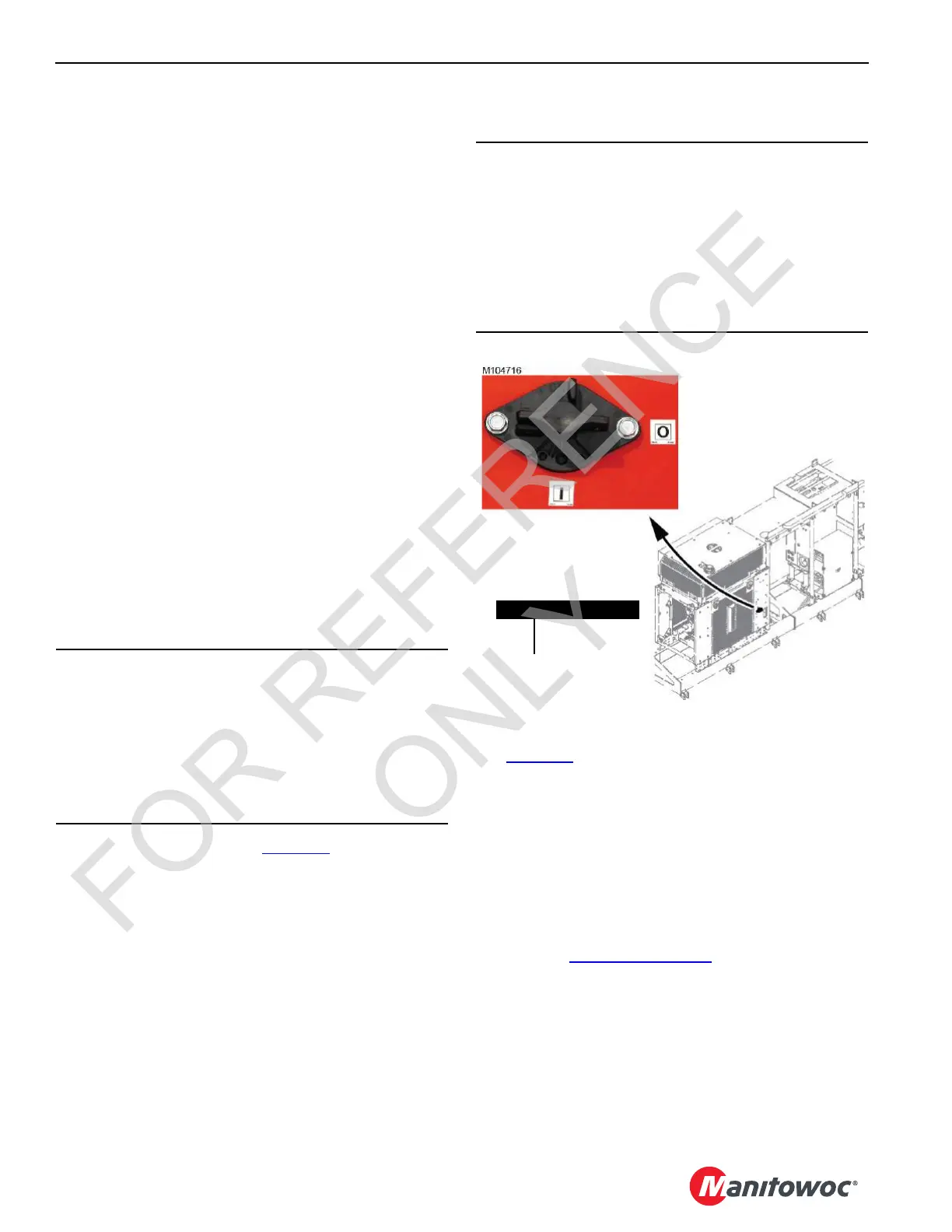

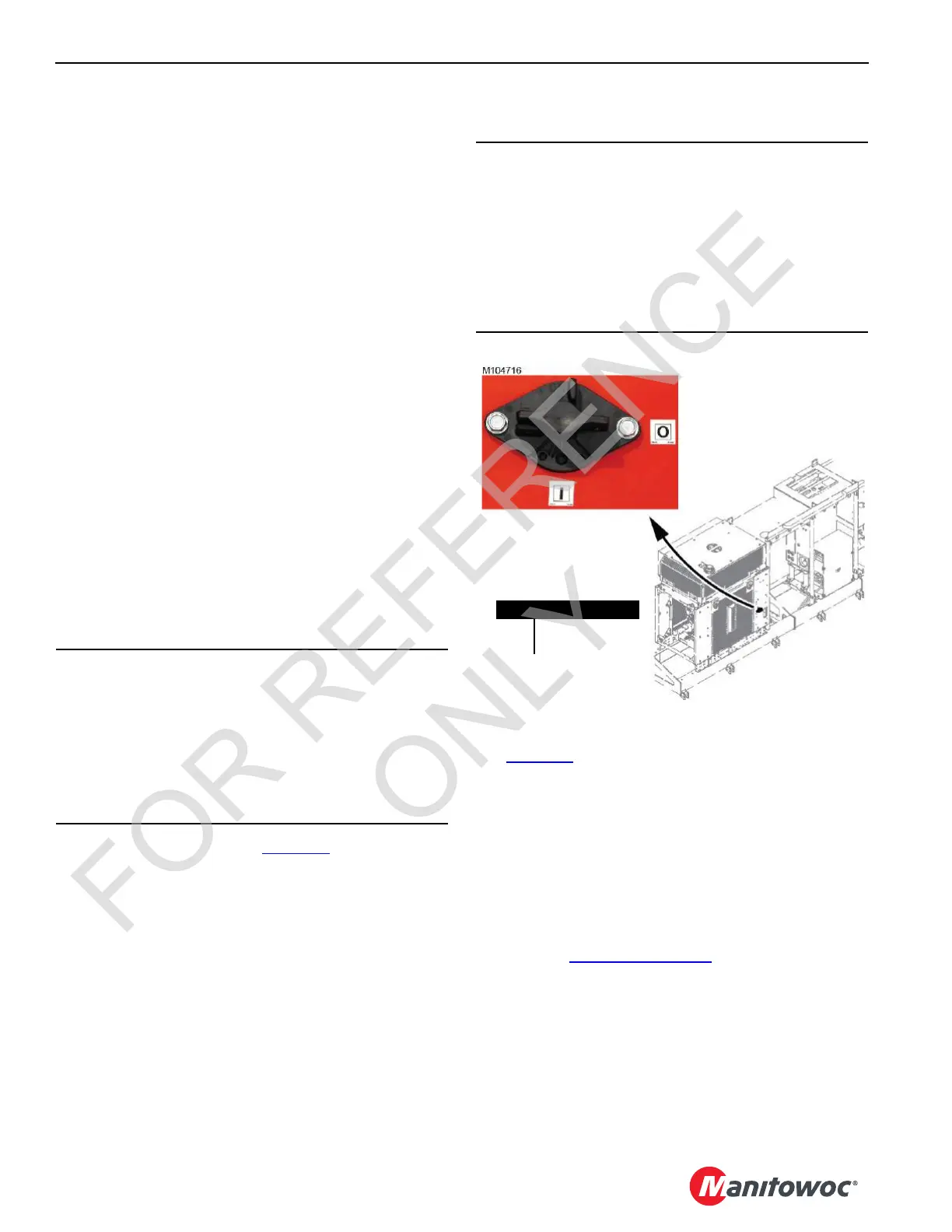

BATTERY DISCONNECT SWITCH

The battery disconnect switch (Figure 7-3) is located on the

engine enclosure on the right side of the rotating bed. It can

be locked with a padlock in either position, ON or OFF.

The switch disconnects the positive side of the batteries from

the crane’s electrical control system.

Turn the switch handle clockwise to connect (turn on) the

batteries to the electrical control system.

Turn the switch handle counterclockwise to disconnect (turn

off) the batteries from the electrical control system.

Use the disconnect switch for the following situations:

• When servicing the crane’s electrical control system

• To help prevent the batteries from discharging when the

crane is stored for extended periods of time

• To prevent the crane from being started by unauthorized

personnel

BATTERY CHARGER (OPTIONAL)

See Figure 7-4 for the following procedure.

An optional auxiliary power unit (APU) equipped with a

5 KW, continuous duty, 60 HZ AC generator and a DC

charging system is available from Manitowoc Cranes for the

following operations when the crane engine is off:

• To charge the crane batteries

• To power the cold weather heaters

• To power any AC lighting on the crane.

If an alternative method of charging is desired, follow the

instructions in Charging on page 7-3

.

The APU can be started with the switch outside the cab.

If the crane is not to be used for more than a few days, the

charger should be plugged into a 240 V

AC

source.

There is a 10 A fuse on the DC output. For charger

troubleshooting and maintenance information, refer to the

manufacturer’s service manual.

CAUTION

Engine Damage

To avoid possible engine fault codes and undesirable

operation, make sure engine ignition switch has been off

five minutes before disconnecting batteries.

Do not rely on this switch to protect crane’s electronic

systems when welding. Disconnect battery cables at

batteries before welding.

CAUTION

Avoid Control System Damage!

Before welding:

• Disconnect the battery cables at the batteries.

• Disconnect the cabling from any control modules that

are in the vicinity of the welding.

Do not rely on the battery disconnect switch to protect the

crane’s electronic control systems when welding.

Item Description

IOn

OOff

FIGURE 7-3

Loading...

Loading...