Manitowoc Published 10-09-2020, Control # 259-06 6-7

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL SWING SYSTEM

SWING GEARBOX OIL CHANGE

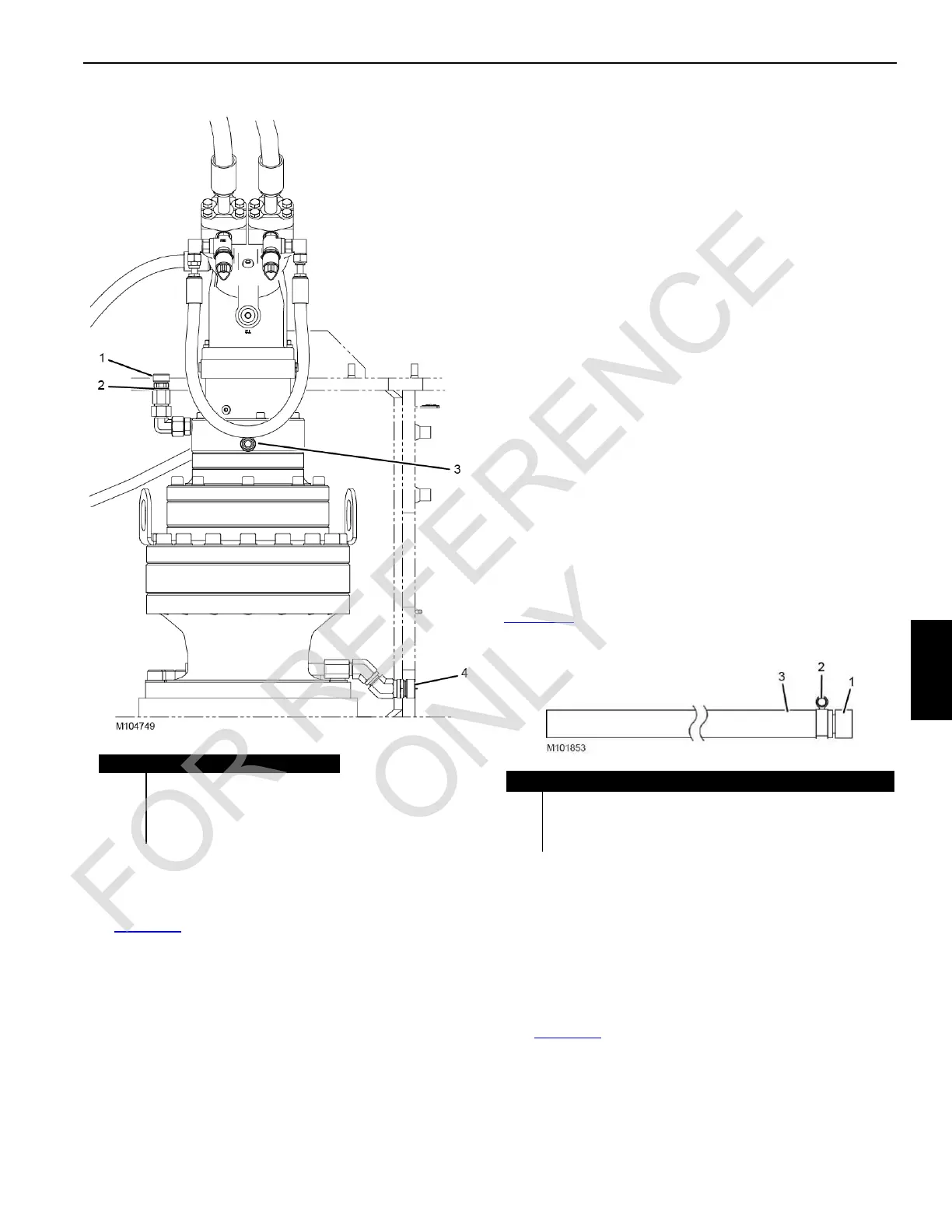

See Figure 6-4.

Swing gearbox maintenance consists of periodically

checking the level and changing the oil.

Gear Oil Specifications

For gear oil specifications and the swing gearbox capacity,

see the Lubrication Guide supplied with the crane.

Oil Analysis

An oil analysis program is the best way to determine the best

oil change interval and the condition of the swing gearbox.

Periodic Maintenance

Initial Drain Interval

Drain and refill the swing gearbox after the first 200 hours of

engine operation.

Oil Level Interval

Check the swing gearbox oil level weekly or every 10 hours

of function operation or every 20 hours of engine operation,

whichever occurs first.

Remove the fill cap/breather (1) and fill the swing gearbox

through the fill port (2) to middle of the sight gauge (3).

Oil Change Interval

Drain and refill the swing gearbox semiannually or every 200

hours of function operation or every 1000 hours of engine

operation, whichever occurs first, unless an alternate interval

has been established through an oil analysis program.

Quick-Drain Valve

The swing gearbox is equipped with a quick-drain valve (4),

which requires use of the quick-drain drainer assembly (see

Figure 6-5

). The quick-drain drainer assembly is stored in

the parts box supplied with the crane.

Oil Change Procedure

Change the oil when the gearbox is warm, not hot.

NOTE: To prevent harmful contaminants from entering a

gearbox, thoroughly clean components before

disconnecting or connecting them.

See Figure 6-4

.

1. Lock out tag out the crane.

2. Remove the dust cap from the quick-drain valve (4).

Item Description

1 Fill Cap/Breather

2 Fill Port

3 Sight Gauge (Qty 2)

4 Quick-Drain Valve

FIGURE 6-4

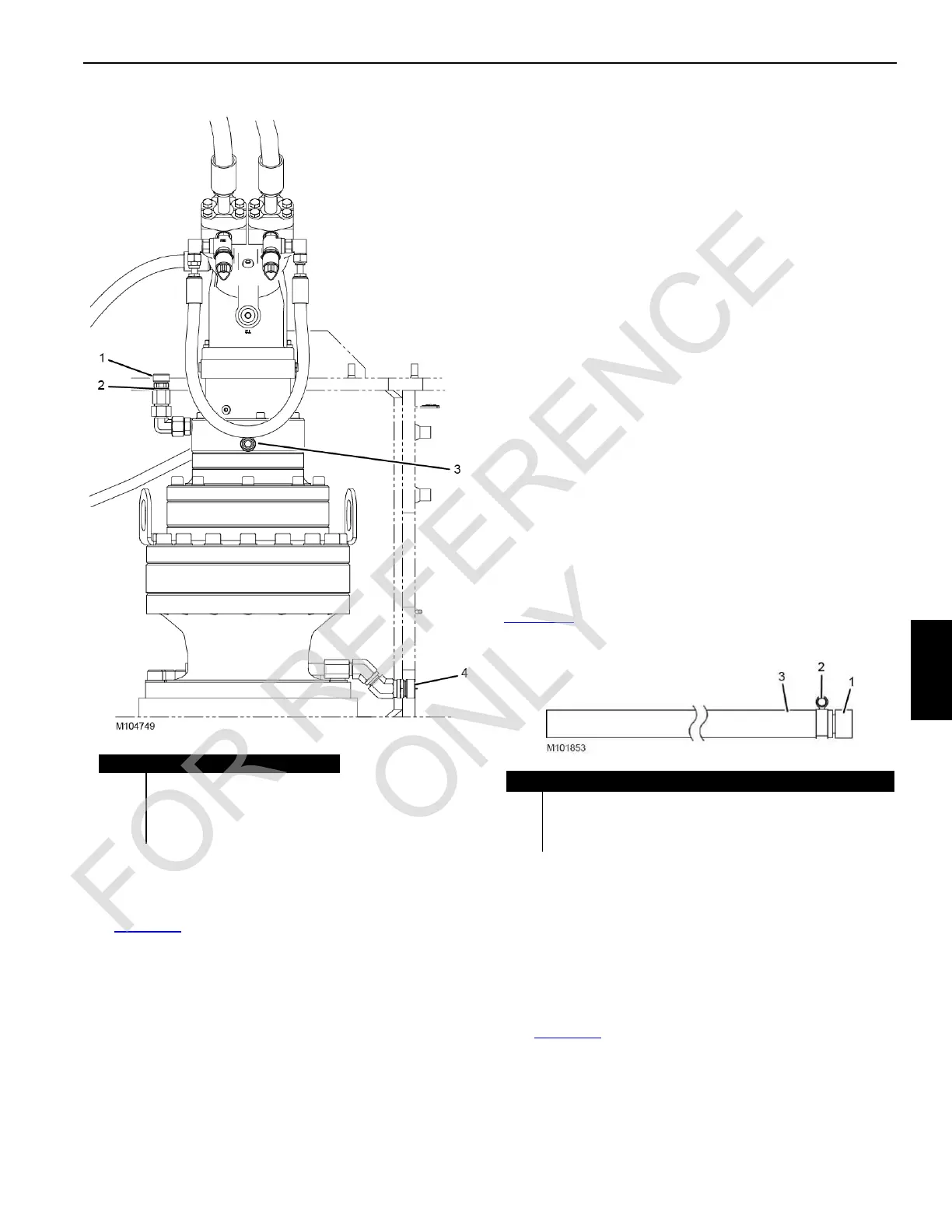

Item Description

1 Quick-Drain Drainer

2 Hose Clamp

3 Hose: 19 mm (3/4 in) Inside Diameter by 3.0 m (10 ft) Long

FIGURE 6-5

Loading...

Loading...