SWING SYSTEM MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL

6-6

Published 10-09-2020, Control # 259-06

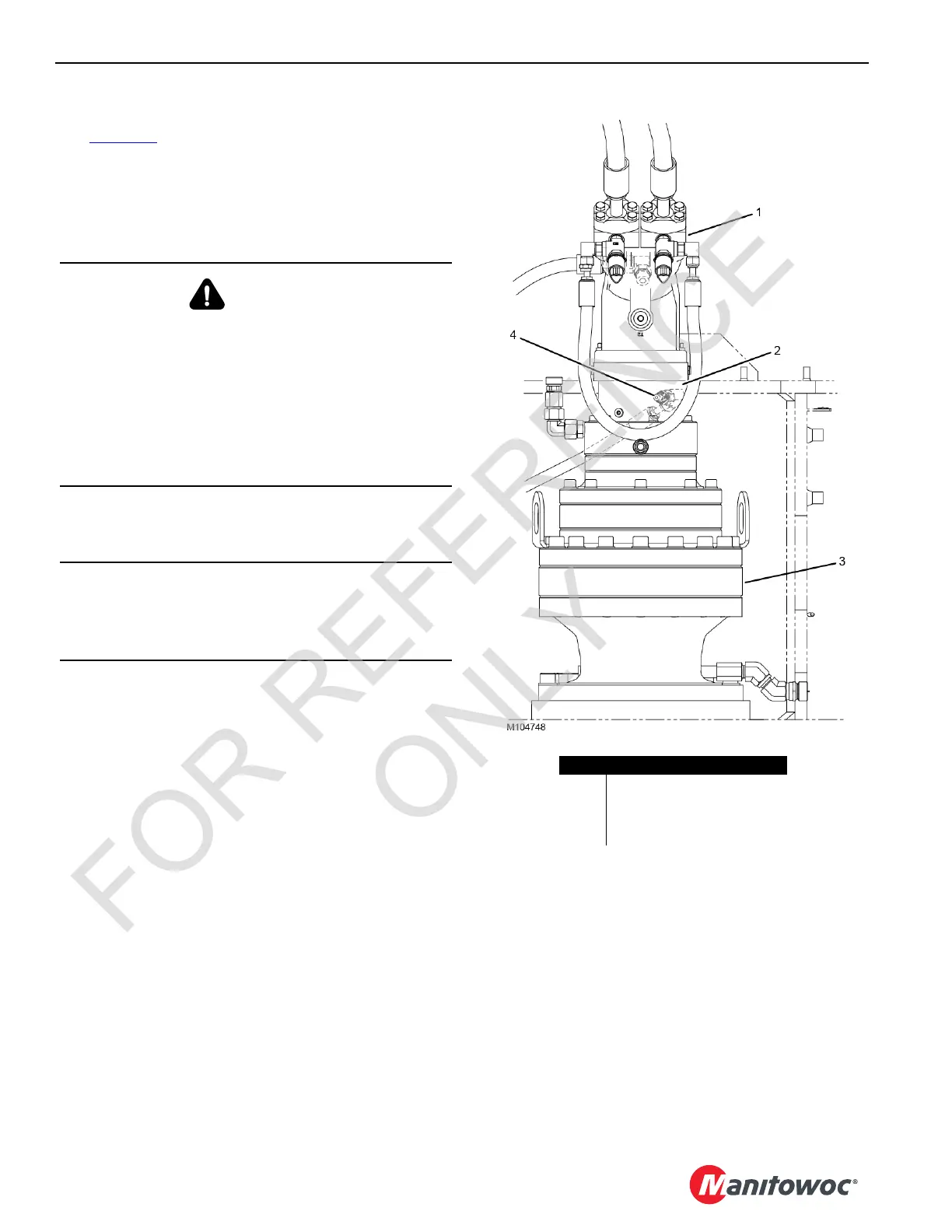

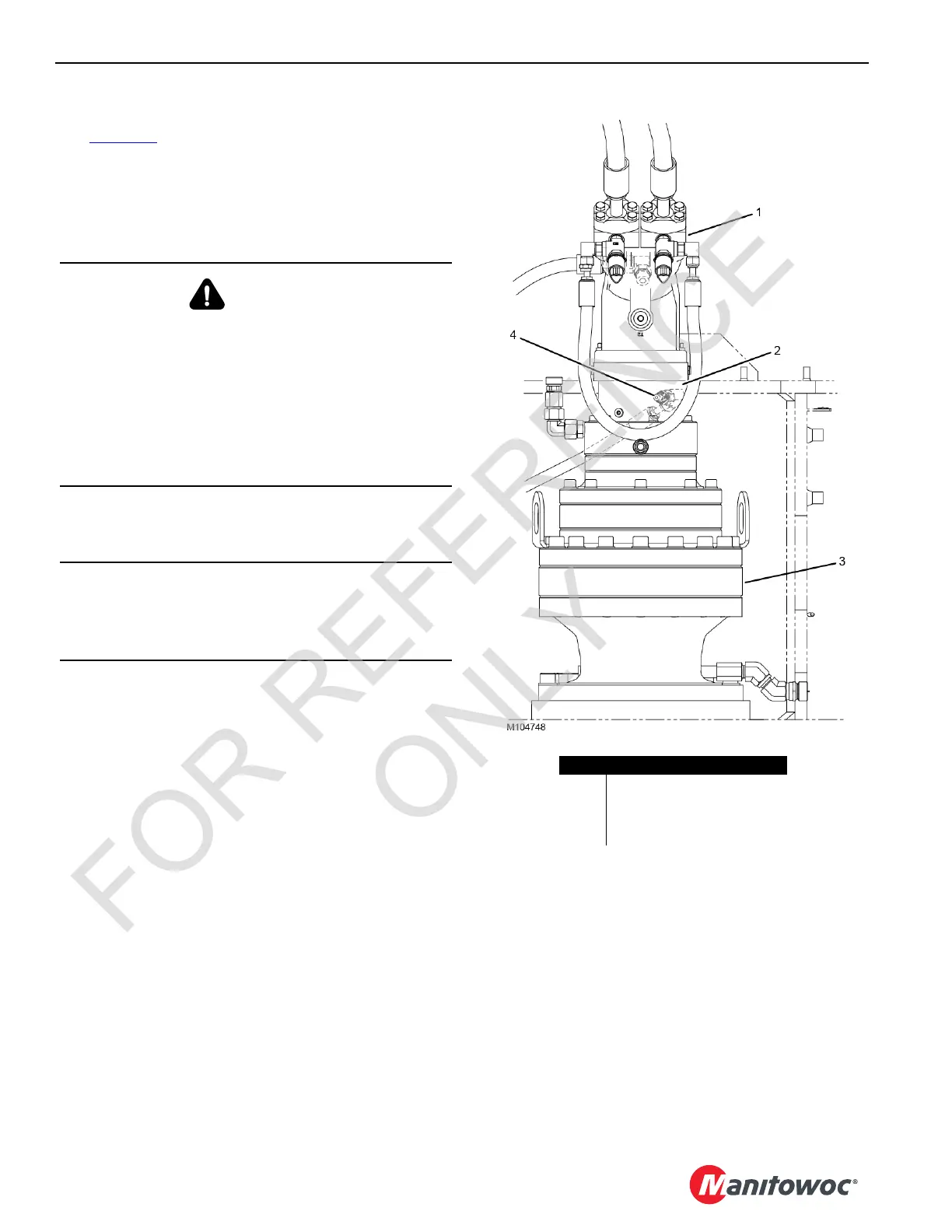

SWING BRAKE MANUAL RELEASE

See Figure 6-3 for the following procedure.

The crane has one swing drive.

When removing or installing the swing drive, the swing brake

must be released to allow alignment of the swing pinion with

the slewing ring gear.

NOTE: A hydraulic hand pump with a pressure gauge is

needed to manually release the swing brake.

1. Stop the engine and lock out tag out the crane.

2. Disconnect the brake hose from the existing elbow in the

brake release port (4).

3. Connect the hand pump hose to the existing elbow with

user-supplied 06 ORFS fittings.

4. To release the brake, pressurize it to 25 bar (363 psi)

with the hydraulic hand pump.

5. Service the swing drive as required.

6. At the completion of servicing, perform the following

procedure:

a. Apply the swing brake by relieving the pressure with

the hand pump.

b. Disconnect the hand pump hose from the existing

elbow in the brake release port.

c. Connect the brake hose to the existing elbow in the

brake release port.

7. Clean up any spilled oil.

WARNING

Unexpected Crane Movement!

When the swing brake is released, the crane can

suddenly swing. Before releasing the swing brake, secure

the crane by lowering the boom onto blocking at ground

level to prevent sudden uncontrolled swinging.

The swing brake manual release procedure is for

servicing purposes only. Do not operate the crane unless

the swing brake is fully operational.

CAUTION

Avoid Damage to Parts!

When releasing the swing brake with the hand pump, do

not exceed 21 bar (300 psi) of pressure.

Item Description

1 Swing Motor

2Swing Brake

3 Swing Gearbox

4 Swing Brake Release Port

FIGURE 6-3

Loading...

Loading...