National Crane Published 5-27-2018 Control # 039-06 7-1

800D SIDE SHIMMING OF BOOM SECTIONS

SECTION 7

SIDE SHIMMING OF BOOM SECTIONS

SECTION CONTENTS

Top/rear Side Pad Adjustment . . . . . . . . . . . . . . . 7-2

Inner Boom Pad Lubrication . . . . . . . . . . . . . . . . . 7-3

Jib Installation And Adjustment . . . . . . . . . . . . . . 7-4

Jib Jack Service & Maintenance . . . . . . . . . . . . . . 7-5

Adding Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Changing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Rust Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

(Optional) Oil Cooler Service & Maintenance . . . 7-6

Swing Drive Service . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Lubrication and Maintenance . . . . . . . . . . . . . . . . 7-8

Disassembly Procedure . . . . . . . . . . . . . . . . . . . . 7-8

Assembly Procedure. . . . . . . . . . . . . . . . . . . . . . . 7-9

Rotation Stop-mechanical . . . . . . . . . . . . . . . . . . 7-10

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . 7-10

Servicing The Control Valves. . . . . . . . . . . . . . . . 7-11

Disassembly and Reassembly of Control

Valves to Replace Seals . . . . . . . . . . . . . . . . . . . 7-11

Replacing Spool Seals. . . . . . . . . . . . . . . . . . . . . 7-11

Unloader Valve Service. . . . . . . . . . . . . . . . . . . . . 7-12

Control Valve Relief Adjustment . . . . . . . . . . . . . 7-13

Mid-inlet Relief Adjustment . . . . . . . . . . . . . . . . . 7-13

Unloader Dump Valve – Air Purging

Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Hydraulic System Description . . . . . . . . . . . . . . . 7-14

Optional Hydraulic Capacity Alert System . . . . . 7-15

System Adjustment . . . . . . . . . . . . . . . . . . . . . . . 7-15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Maintenance & Repair . . . . . . . . . . . . . . . . . . . . . . 7-18

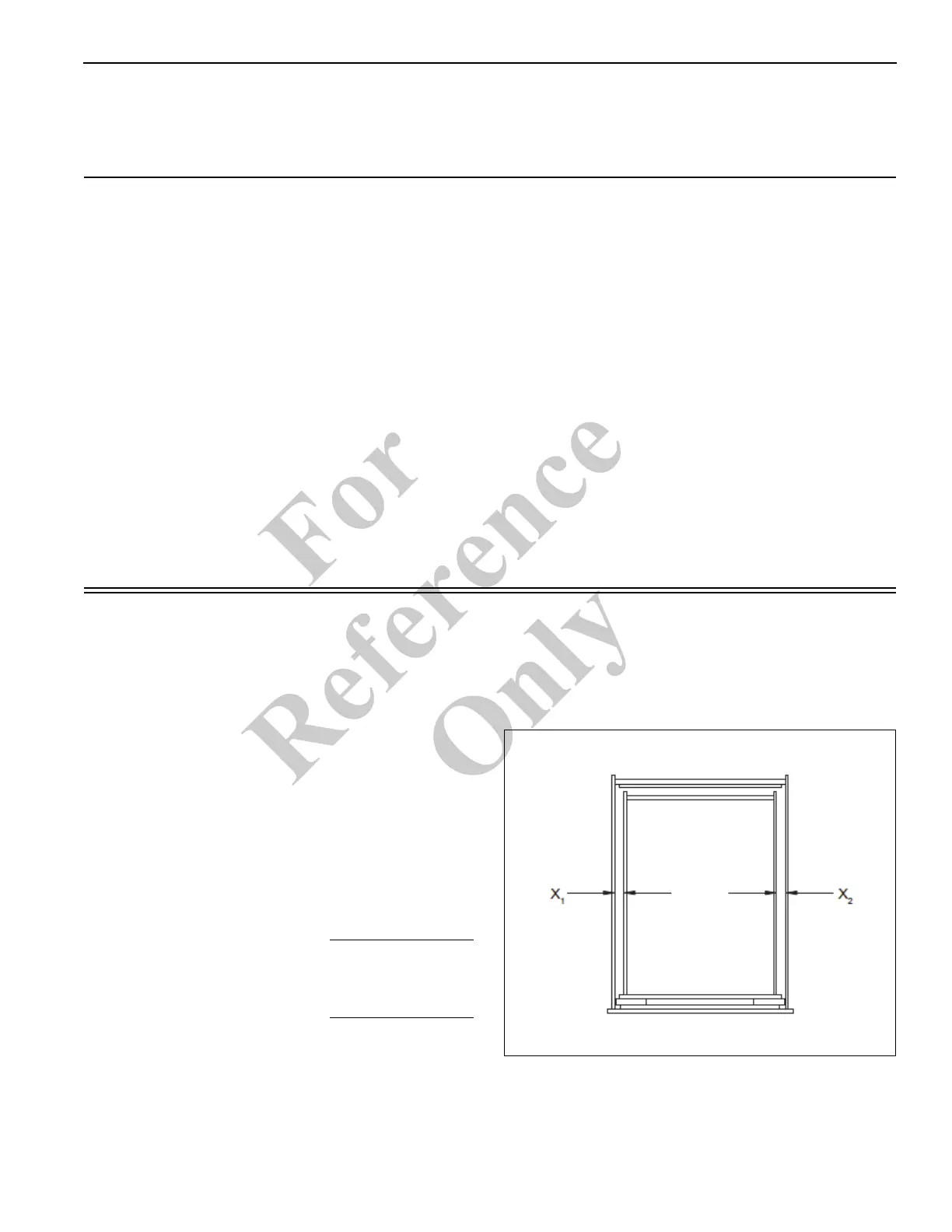

Center inner boom section in outer boom section.

X

1

= X

2

Calculate shims required.

Gaps X

1

= X

2

= 0.56 in (14.3 mm).

Wear pad thickness (t

wp

) = 0.44 in (11.1 mm).

Add shims as required [each shim is 0.03 in (0.8 mm)] to

tighten the pads so that there is 0.03 in - 0.09 in (0.8 mm -

2.4 mm) total clearance between the sections. In some

cases it will be necessary to have an unequal number of

shims behind the pads at the top and bottom side pad

locations.

At each pad location add qty-1 0.06 in (1.6 mm) and qty-

1.03 in (0.8 mm) shim for a total clearance of 0.03 in

(0.76 mm).

X1 = 0.56in (14.3mm)

- t

wp

=

0.44 in (11.1 mm)

clearance before shims 0.12 in (3.2 mm)

Add shims 0.03 in (0.8 mm)

0.06 in (1.6 mm)

Final clearance 0.03 in (0.8 mm)

Fo

r

Reference

Only

Loading...

Loading...