National Crane Published 5-27-2018 Control # 039-06 11-5

800D HOIST

MAINTENANCE AND SERVICE

For safe and consistent operation of this hoist a regular

program of preventive maintenance is strongly

recommended. Regular oil changes with the correct oil for

the ambient temperature conditions and an annual

inspection of the wear components will help ensure a long

life for your planetary geared products.

Maintenance Scheduling

The owner is to ensure proper inspection intervals, in

compliance with the API RP 2D Section 4 requirements or

the ANSI B30.5, 5-2.3, and will review hoist usage

categories on a periodic basis. A Qualified Inspector should

perform all maintenance and inspections.

• For hoists in occasional use, less than 10 hours per

month, API RP 2D recommends a pre-use inspection

and an annual 12-month inspection based on average

use over a quarter.

• For hoists in moderate use, more than 10 but less than

50 hours per month, API RP 2D recommends a pre-use

inspection, quarterly inspection, and an annual 12-

month inspection based on average use over a quarter.

• For hoists in heavy use, more than 50 hours per month,

API RP 2D recommends a pre-use inspection, monthly

inspection, quarterly inspection, and an annual 12-

month inspection.

Oil Level Maintenance

The oil level in the gearbox and brake housing be checked

and adjusted as part of the pre-use inspection. If the oil level

drops frequently or oil leakage is detected during an

inspection, maintenance should be performed to correct any

problems.

Oil Change Interval

The oil in the gearbox and brake sections is recommended to

be changed after first 50 hours of operation and every 1000

hours or 6 months of usage.

Hoist Brake Oil

Check Hoist Brake Oil

.

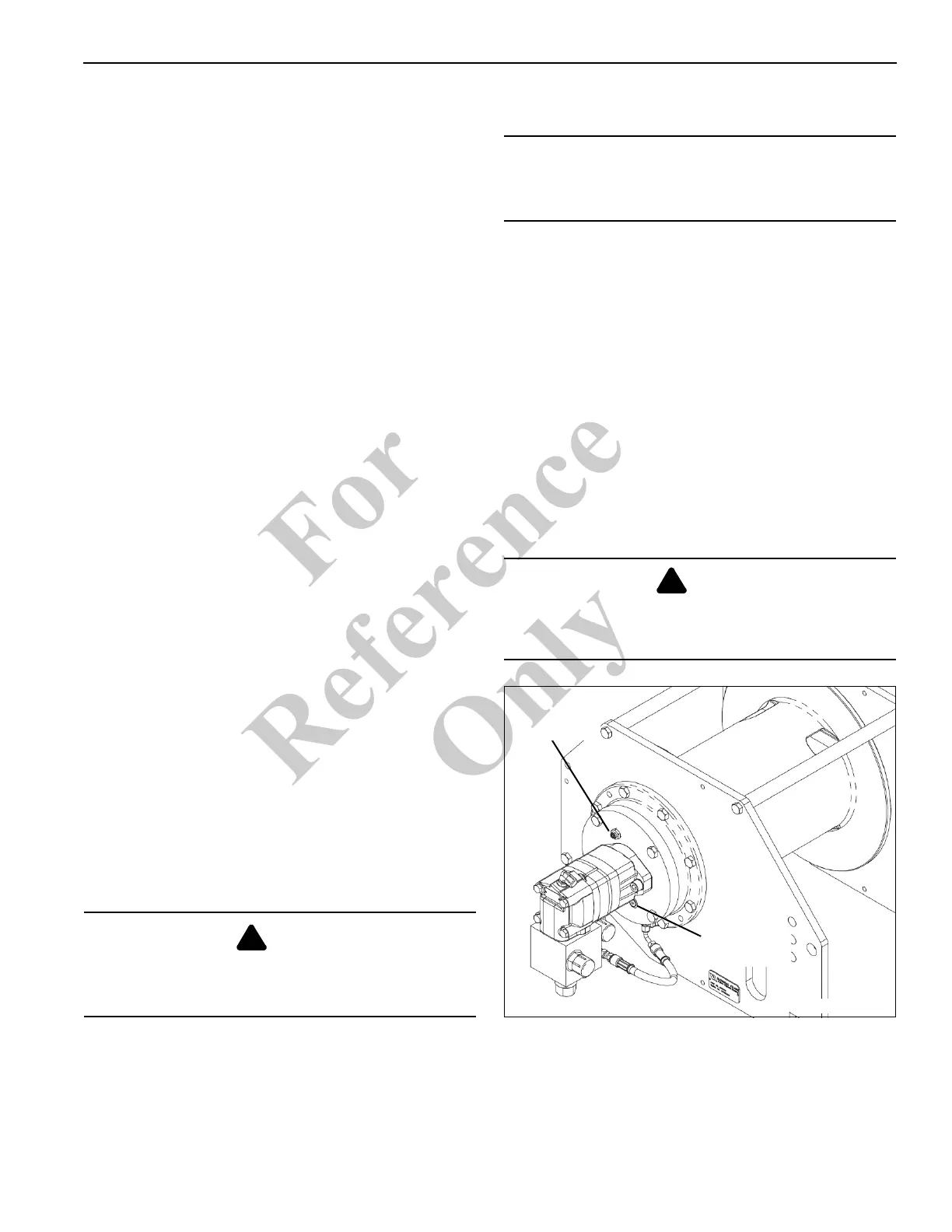

To check the hoist brake oil, remove the vent and fill plug

(Figure 11-1) and visually inspect the oil level. The maximum

fill capacity for the hoist brake is 0.23 liter (0.25 quart).

Drain /Add New Hoist Brake Oil

To drain and add new oil, remove the drain plug

(Figure 11-1), inspection plug and vent plug and drain the

brake oil. Reinstall drain plug and add fluid at the brake oil

vent hole until oil is at the bottom level of the inspection hole.

Install the inspection plug and the oil vent and fill plug. The

hoist brake fill capacity is 0.23 liter (0.25 quart).

NOTE: Brake lubricants are satisfactory for operation in

temperatures from -23° C to 66° C

(-10° F to +150° F). For operation outside this

range, contact Manitowoc Crane Care for

recommendations.

.

DANGER

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state or federal regulations.

CAUTION

The maximum fill capacity for the hoist brake is 0.23 liter

(0.25 quart). Over-filling the hoist brake can cause

damage to the hoist.

DANGER

Do not use EP type gear lubes in the brake section. This

may prevent proper operation and cause the load to fall

resulting in serious injury or death.

FIGURE 11-1

9468

Brake Oil Vent

and Fill Plug

Brake Oil Drain

Plug

Fo

r

Reference

Only

Loading...

Loading...