MAINTENANCE 800D

3-4 Published 5-27-2018 Control # 039-06

Inspection

All hoist cable in service needs to be inspected on a daily,

monthly, and quarterly basis. Cable which has been idle for a

period of a month or more must be given a thorough

inspection before it is placed in service. These inspections

should cover all types of deterioration including:

• Distortion such as kinking, crushing, un-stranding, bird

caging, main strand displacement or core protrusion.

• Loss of cable diameter in a short cable length or

unevenness of outer strands indicates the cable needs

to be replaced.

• Significant corrosion.

• Broken or cut strands.

• Number, distribution and type of visible broken wires.

• Core failure in rotation resistant ropes.

• Prior electrical contact with a power line or other electric

arc damage.

• Significantly corroded, cracked, bent, or worn end

connections.

Inspect only the outer surface of a cable. Never attempt to

open the cable.

Pay particular attention to areas of the rope where wear and

other damage is likely to occur:

• Pick-up Points: Sections of wire rope that are repeatedly

stressed during each lift, such as those sections in

contact with sheaves.

• End Attachments: The point where a fitting is attached to

the wire rope or the point where the wire rope is attached

to the hoist drum.

• Abuse Points: The point where the wire rope is

subjected to abnormal scuffing and scraping.

Daily Inspections

All cable in continuous service must be inspected at the

beginning of each work day. Inspect the eye end and length

of cable that is used in daily operation. The end should be

inspected for abrasion, corrosion, broken wires, and loose or

broken servings. Inspect the remainder of the cable length

used for daily operations for points showing kinks, sharp

bends, or any other evidences of damage or excessive wear.

Monthly Inspections

Inspect the eye end and length of cable normally used in

daily operations. Examine the rest of the cable for kinked,

crushed or otherwise damaged points.

Periodic Inspections

Wire rope should be inspected periodically/annually, or at a

shorter time interval, if necessitated by environmental or

other adverse conditions, and shall cover the entire length of

the wire rope. Periodic inspection should include all previous

items listed under Inspection, plus the following:

• Inspect for severely corroded or broken wires at end

connections.

• Inspect wire rope in areas subjected to rapid

deterioration such as:

- Sections in contact with saddles, equalizer sheaves,

or other sheaves where wire rope travel is limited.

- Sections of wire rope at or near terminal ends where

corroded or broken wires may protrude.

• Inspect boom nose sheaves, hook block sheaves, boom

extension/extension sheaves, auxiliary boom nose

sheaves, and hoist drums for wear. Damaged sheaves

or hoist drums can accelerate wear and cause rapid

deterioration of the wire rope.

Inspect the eye end of the cable for greater wear than the

rest of the cable. If the cable is in good condition, reverse the

cable on the drum so that the wear is equalized along the

total length of the cable.

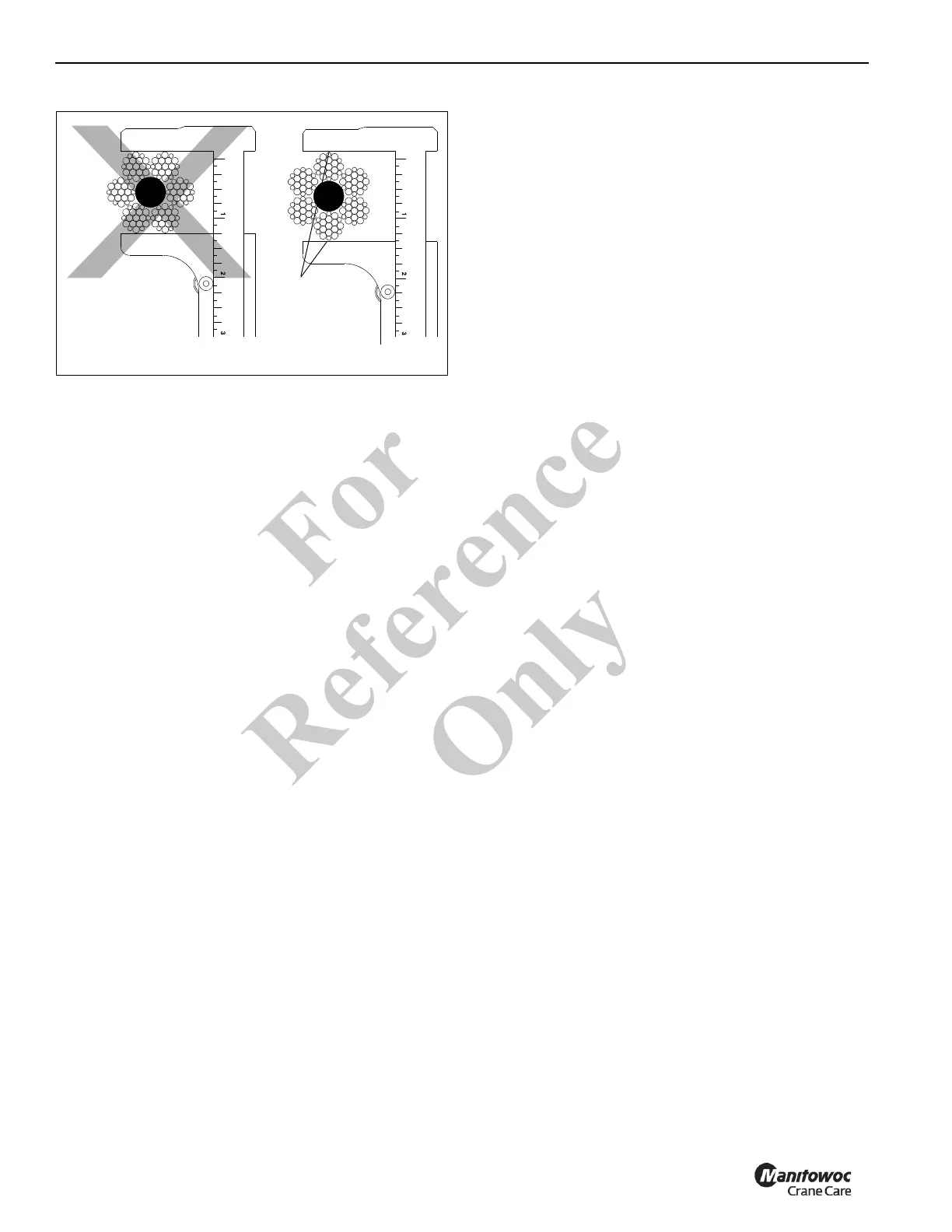

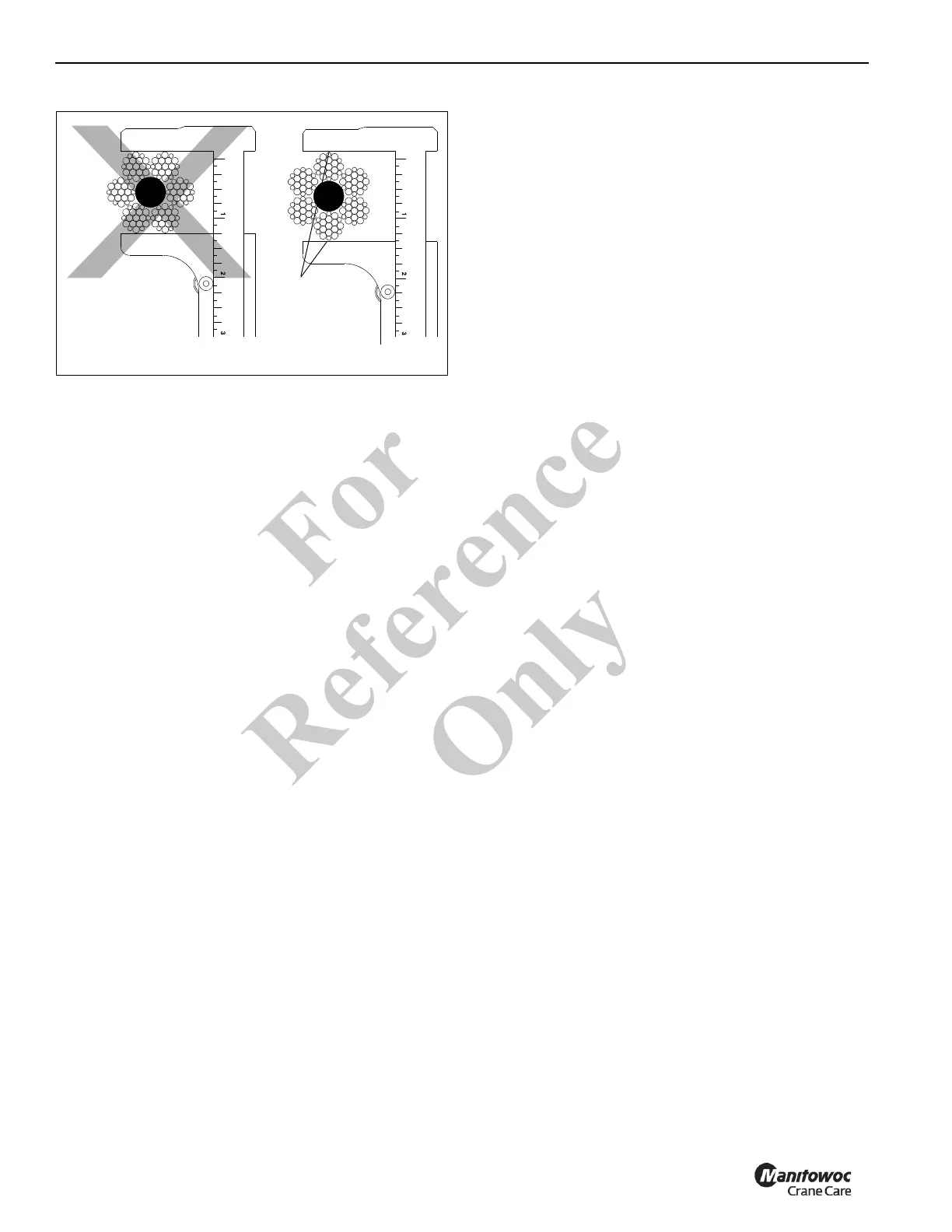

Wire Rope Replacement

No precise rules can be given for determination of the exact

time for replacement of wire rope since many variable factors

are involved. Determination regarding continued use or

replacement of wire rope depends largely upon the good

judgment of an appointed and qualified person who

evaluates the remaining strength in a used rope after

allowance for any deterioration disclosed by inspection.

Wire rope replacement should be determined by the

following information excerpted from a National Consensus

Standard as referenced by Federal Government Agencies

and as recommended by National Crane. All wire rope will

eventually deteriorate to a point where it is no longer usable.

Fo

r

Reference

Only

Loading...

Loading...