National Crane Published 5-27-2018 Control # 039-06 3-5

800D MAINTENANCE

Wire rope shall be taken out of service when any of the

following conditions exist:

• In rotation resistant ropes: two randomly distributed

broken wires in six rope diameters or four randomly

distributed broken wires in 30 rope diameters.

• Severe corrosion as evidenced by pitting

• Necking down of the rope indicates core failure.

• Kinking, crushing, bird caging, or any other damage

resulting in distortion of the rope structure.

• Evidence of heat damage.

• Reductions from nominal diameter of more than 5%.

• One outer wire broken at its point of contact with the core

of the rope which has worked its way out of, and

protrudes or loops out from the rope structure.

• In running ropes, six randomly distributed broken wires

in one lay or three broken wires in one strand in one lay.

• National Crane recommends that for cable extended

booms, a single damaged wire rope assembly shall

require replacement of the entire set of extension

cables.

• National Crane recommends that boom extension

cables be replaced every seven (7) years.

Adjustments and Repairs

Before adjustments and repairs are started on a crane, the

following precautions shall be taken as applicable:

1. A warning tag should be placed in a conspicuous

place at the controls stating that the machine

requires adjustment or repair before it can be

operated.

2. The crane should be placed where it will cause the

least interference with other equipment or

operations in the area.

3. All controls at the OFF position and all operating

features secured from inadvertent motion by brakes

or other means.

4. All methods used to start the truck’s engine

rendered inoperative.

5. Power plant stopped or disconnected at take off.

6. Boom lowered to the ground or otherwise secured

against dropping.

7. Load block lowered to ground or otherwise secured

against dropping.

8. Relieve hydraulic oil pressure from all hydraulic

circuits before loosening or removing hydraulic

components.

After adjustments and repairs have been made, the crane

shall not be returned to service until all guards have been

reinstalled, trapped air removed from hydraulic system if

required, safety devices reactivated, and maintenance

equipment and all warning tags removed.

Any hazardous conditions disclosed by the inspection

requirements listed above shall be corrected before

operation of the crane is resumed. Adjustments and repairs

shall be done only by designated personnel who are properly

trained. Use only National Crane supplied parts to repair the

crane.

Seizing Wire Rope

It is important to seize the ends of rotation resistant wire

ropes to prevent the displacement and unraveling of the

individual wires and strands at the ends. All preformed and

non-preformed styles of wire rope should be seized prior to

cutting. Seizings must be placed on both sides of the point

where the wire rope is to be cut.

The two preferred methods for seizing wire ropes are:

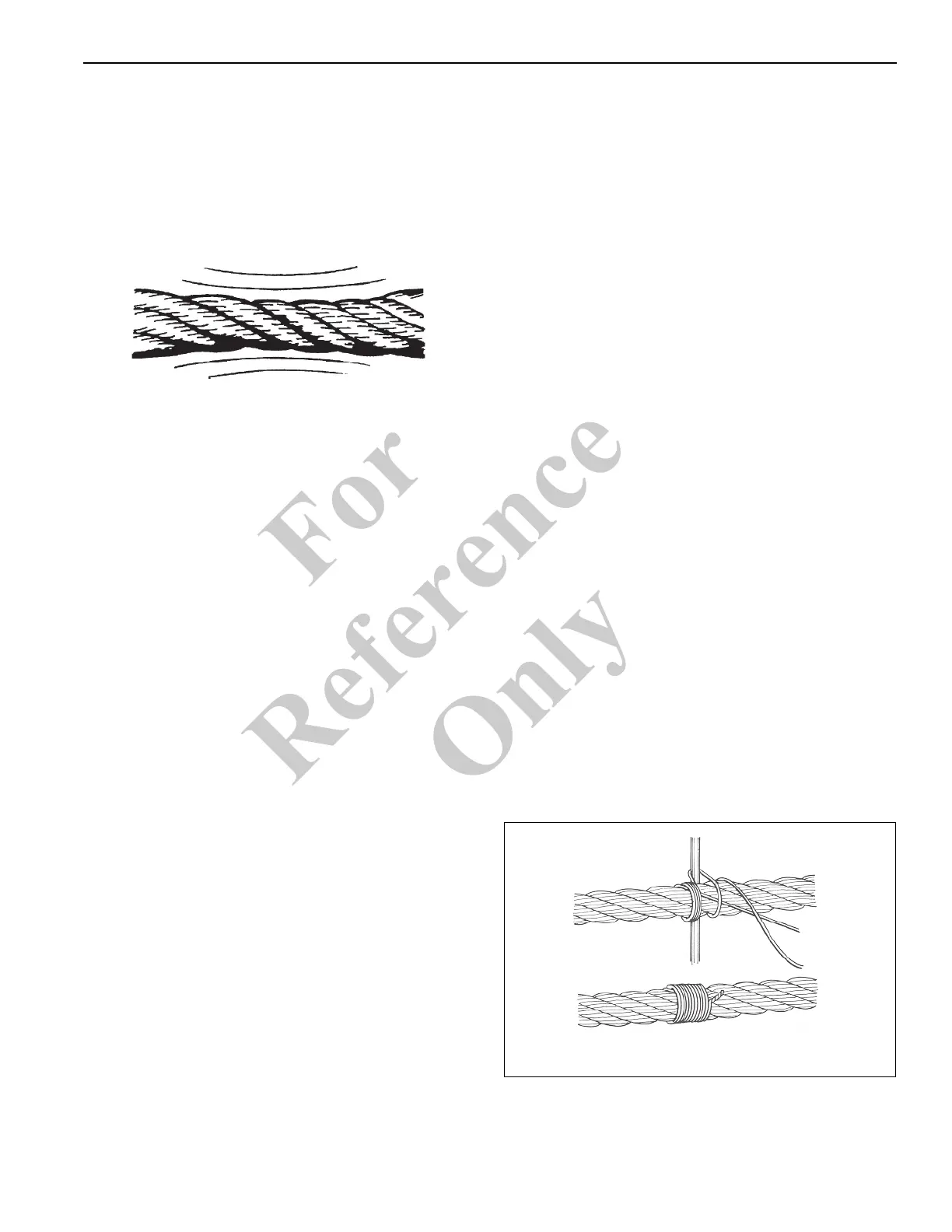

Method 1

Using a length of soft annealed wire Figure 3-2, place one

end in the groove between two strands of the wire rope. Turn

the long end of the annealed wire at right angles to the wire

and wrap it tightly over the portion in the groove.

The two ends of the annealed wire should be twisted

together tightly. Cut off the excess wire and pound the twist

flat against the wire rope.

Fo

r

Reference

Only

Loading...

Loading...