SIDE SHIMMING OF BOOM SECTIONS 800D

7-6

Published 5-27-2018 Control # 039-06

Adding Oil

1. With saddle fully lowered and piston depressed, set jack

in its upright level position and remove oil filler plug.

2. Fill until oil is level with filler plug hole.

Changing Oil

1. For best performance and longest life, replace the

complete oil supply at least once a year.

2. To drain the oil, remove the filler plug.

3. Lay the jack on its side and allow the oil to run out into

suitable drain pin. The oil will run slowly because air

must enter as oil drains out.

4. Be careful to prevent dirt or foreign matter from entering

the system.

5. Replace with proper oil as described above.

Lubrication

Add proper lubrication oil to all pivoting sections every three

months.

Rust Prevention

Check ram every three months for any sign of rust or

corrosion. Clean as needed and wipe with an oil saturated

cloth.

Note: When not in use, always leave the saddle and ram

all the way down.

TROUBLESHOOTING

(OPTIONAL) OIL COOLER SERVICE &

MAINTENANCE

The heat exchanger must be kept clean to allow for efficient

operation of the cooler system. Frequent washing of the heat

exchanger core will eliminate oil film, road dirt and other

foreign object buildup on the heat exchanger fins which

reduces cooling efficiency.

Frequent inspection and tightening of hose clamp line

connections will eliminate the possibility of end connection

failure due to back pressure from cold startup. If cooler

system fails to provide adequate performance, reduced air or

oil flow through the heat exchanger is the probable cause.

The cooling fan should be inspected for proper operation

(see Specifications). Any obstructions in airflow should be

corrected (cooler too close to other truck components,

foreign matter in heat exchanger fins, etc.) All hydraulic lines

should be periodically checked for obstructions, hose kinks

or other flow restrictions.

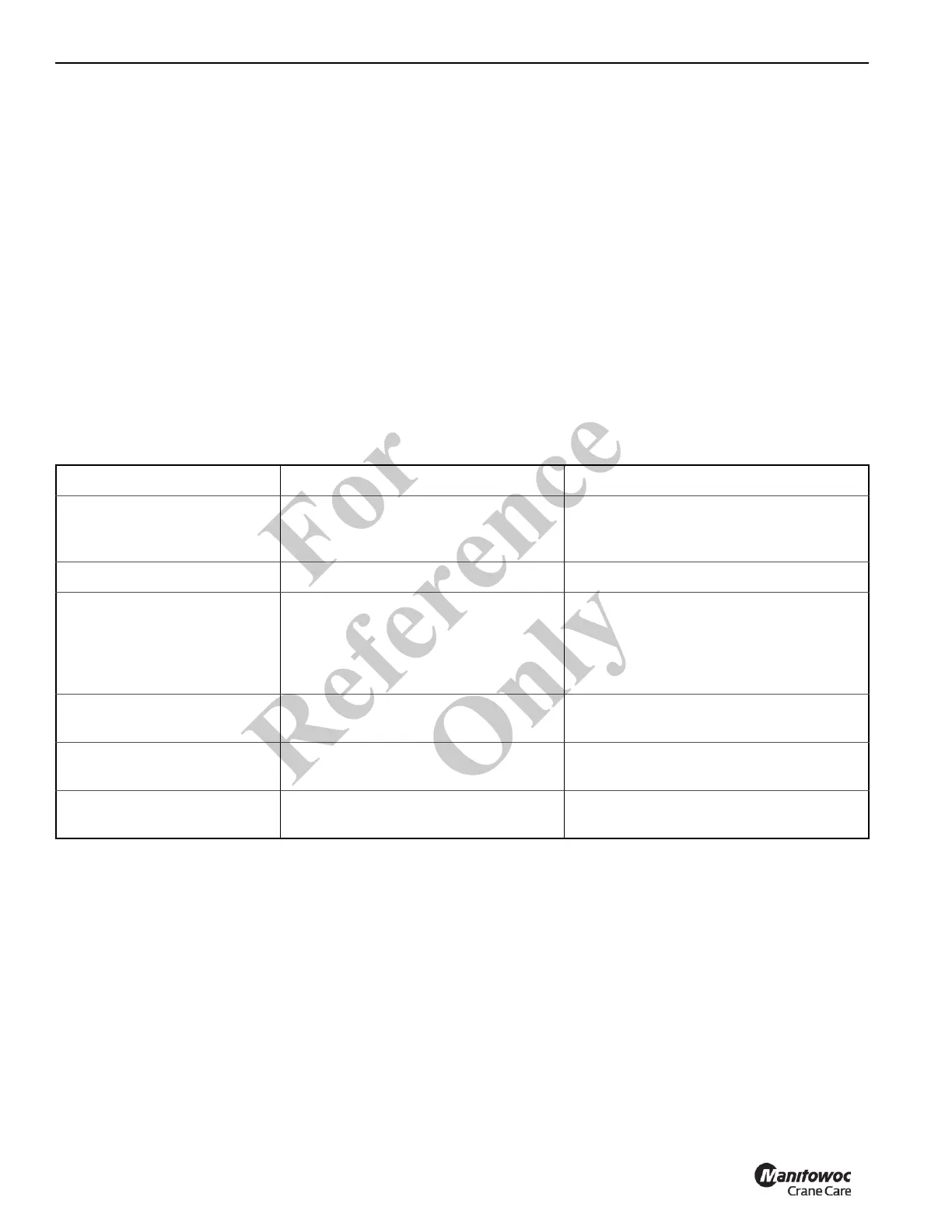

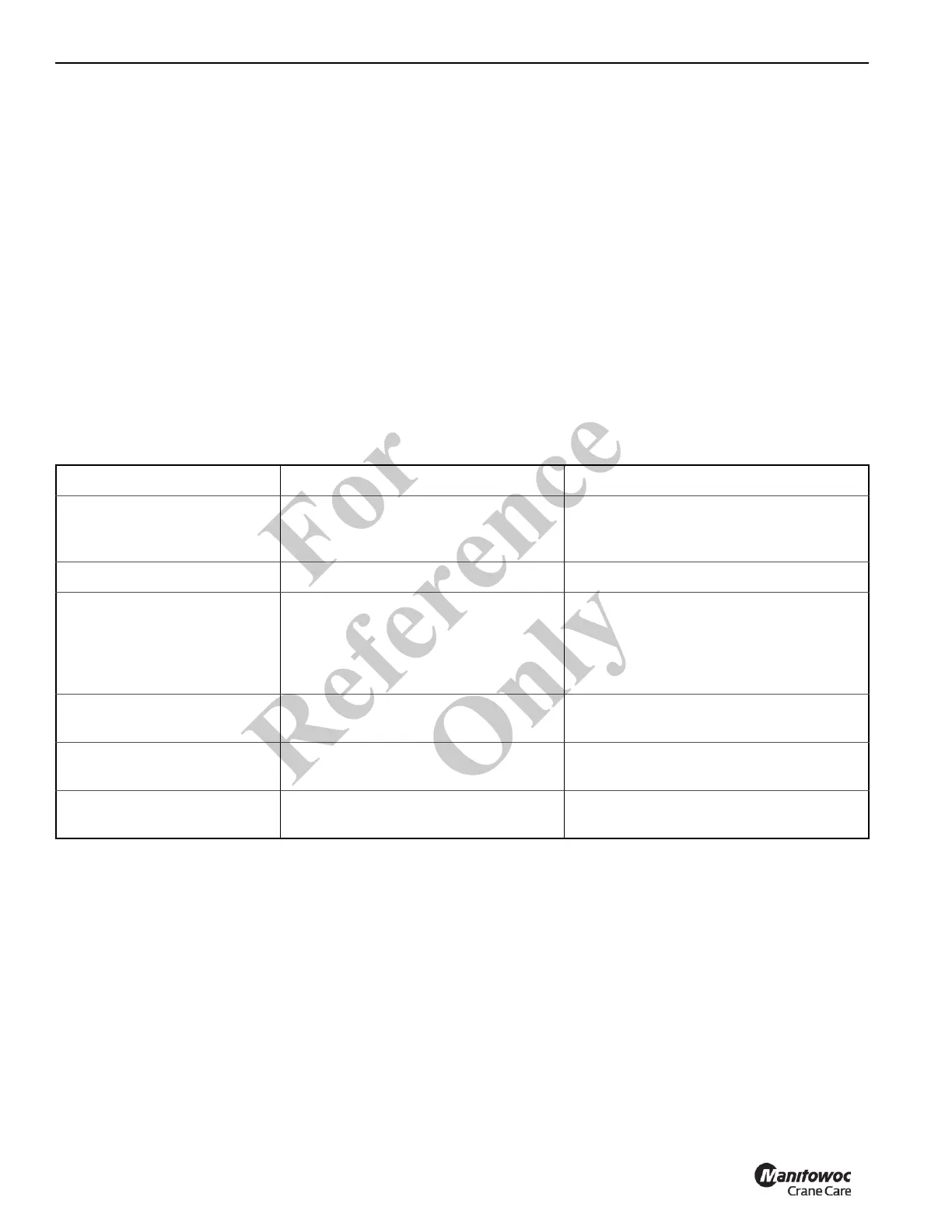

Symptom Possible Cause(s) Corrective Action

Will not lift load 1. No oil in system

2. Release valve not closed

1. Add oil to reservoir tank through oil filler

hole

2. Turn handle clockwise tightly

Will lift load only part way Oil level low Add oil to reservoir tank through oil filler hole

Will lift load but will not hold 1. The following valve or valves leaking:

a. Suction valve

b. Delivery valve

c. Release valve

4. Packings worn out or defective

1. Replace jack

2. Replace jack

Jack will not lower Release valve stuck, probably dirt or

foreign matter

Transfer load then replace dirty oil, flush oil

reservoir with kerosene

Poor lifting 1. Dirty oil

2. Air in hydraulic system

1. Change hydraulic oil

2. Purge air from system

Poor pumping action Oil seal for pump unit worn out or

defective

Replace jack

Fo

r

Reference

Only

Loading...

Loading...