National Crane Published 5-27-2018 Control # 039-06 9-9

800D INSTALLATION

SECTION MODULUS TABLES

The following tables will determine the section modulus of

the truck frame. Always measure the truck frame and check

the tables to be sure that any truck factory listed section

modulus is correct.

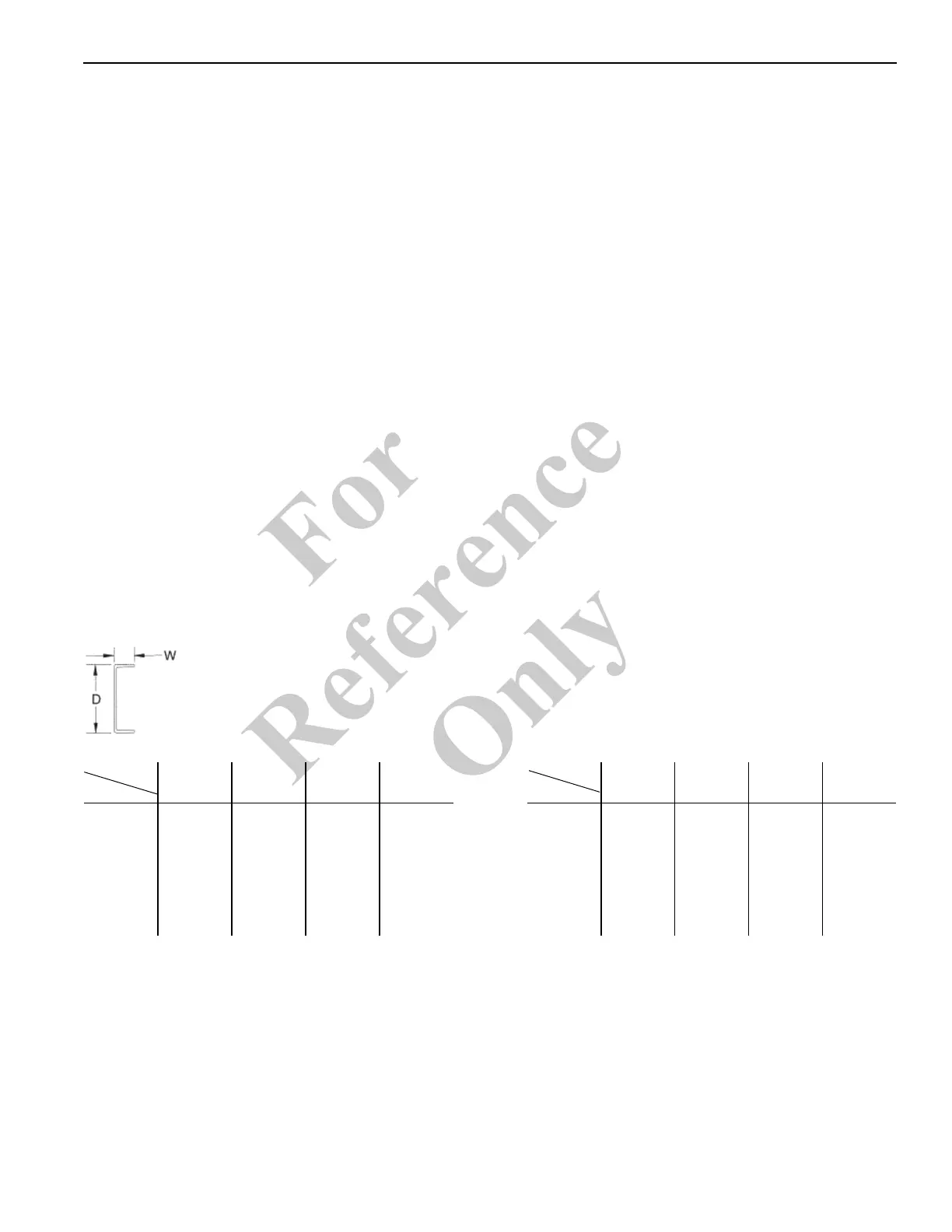

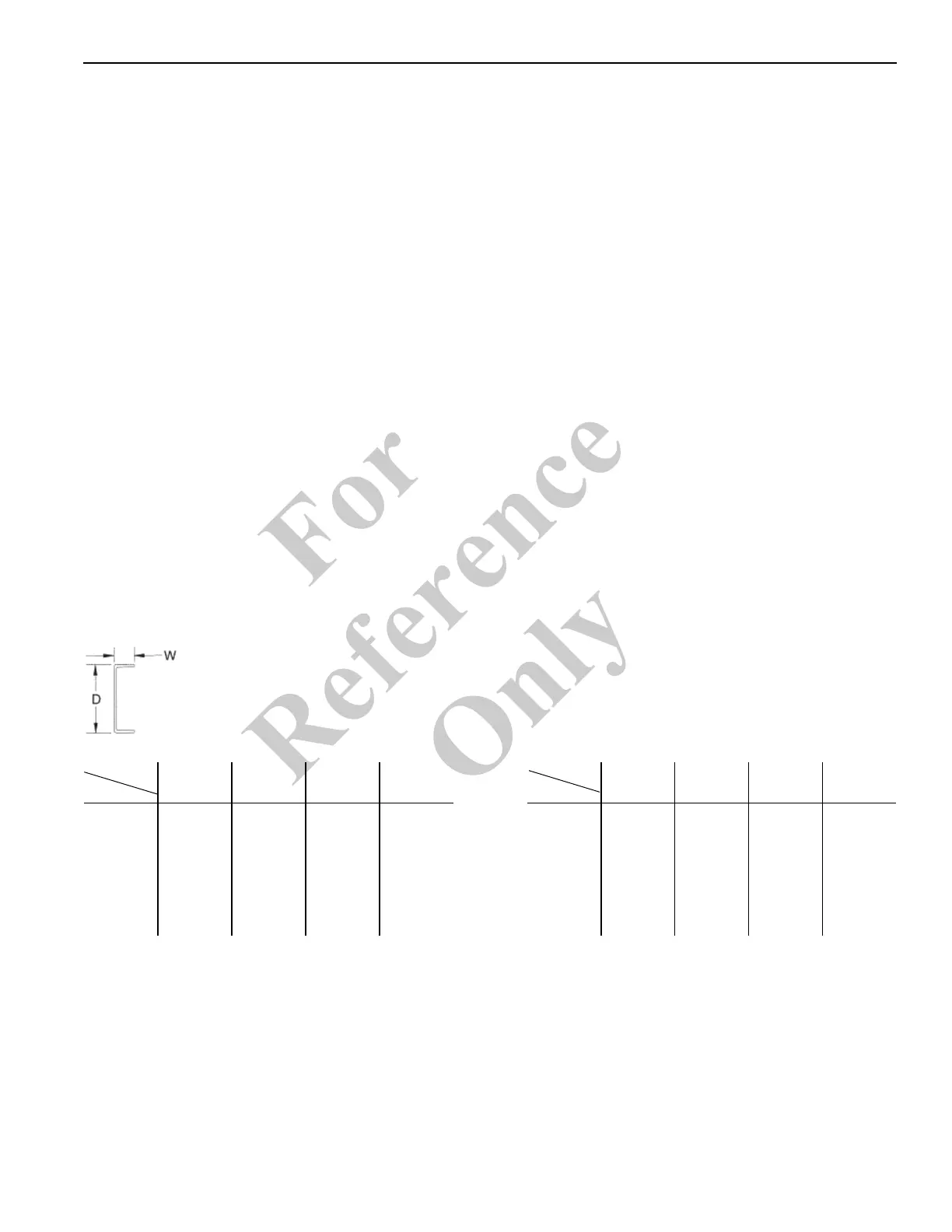

1. Channel (Table A). Table A provides the section

modulus of channel frames in thicknesses of 3/16 in

(4.76 mm), 1/4 in (6.35 mm), 5/16 in (7.94 mm), and 3/8

in (9.52 mm) with each grouping a flange width and web

depth column. When the depth of frame channel and

flange width is known, the point at which these two lines

intersect is the section modulus from that particular

channel.

If the section modulus of the channel does not meet the

requirements, the channel should be reinforced in the

most applicable method following.

2. Channel Reinforcement (Table A). In order to provide

more strength, a channel of suitable thickness can be

added to the existing frame. The depth and flange width

of this channel should be chosen so it fits over the

existing frame. The section modulus of the needed

channel is obtained from Table A and should be added

to the section modulus obtained from the truck frame.

3. Angle Reinforcement (Table B). If the truck is

reinforced with an angle, refer to Table B for the data on

the added strength provided by the angle. Add this to the

section modulus of the channel obtained from Table A.

4. Fish Plate Reinforcement (Table C). The frame can be

strengthened by adding a fish plate of suitable thickness

and depth equal to the frame. The section modulus of

the fish plate can be obtained from Table C and this must

be added to the section modulus of the frame to obtain

the total section modulus.

5. Angle Under Reinforcement (Table D). This table lists

the section modulus of an angle with the flange under

the truck frame that is added to a frame with an angle

reinforcement already added. Add the section modulus

from Table D to the section modulus obtained from

tables A and B to determine total section modulus.

The edges of the reinforcing angles or channels are to be

flush with the edges of the frame.

Welding. Two rows of 1 in (25.4 mm) diameter plug welds

are to be placed in a staggered pattern of the web; the rows

to be spaced 5 in (127 mm) apart with welds at an interval of

4 in (102 mm). Do not weld on the flanges.

Where thickness, depth or flange width vary, interpolation

between tables or variables within a given table will provide

the strength for the section.

If you have any questions concerning frame strength or

reinforcing, contact National Crane before proceeding.

TABLE A

Section Modulus in

3

(cm

3

)

THICKNESS 3/16 in (4.76 mm) THICKNESS 1/4 in (6.35 mm)

2½ (64) 3 (76) 3½ (89) 4 (102) 2½ (64) 3 (76) 3½ (89) 4 (102)

8 (203)

9 (229)

10 (254)

11 (279)

12 (305)

13 (330)

14 (356)

15 (381)

5.3 (87)

6.3 (103)

7.3 (120)

8.4 (138)

9.5 (156)

10.8 (177)

12.0 (197)

13.4 (220)

6.0 (98)

7.1 (116)

8.2 (134)

9.4 (154)

10.6 (174)

11.9 (195)

13.3 (218)

14.7 (241)

6.7 (110)

7.9 (130)

9.1 (149)

10.4 (170)

11.7 (192)

13.1 (215)

14.6 (239)

16.1 (264)

7.5 (123)

8.7 (143)

10.0 (164)

11.4 (187)

12.8 (210)

14.3 (234)

15.9 (261)

17.5 (287)

8 (203)

9 (229)

10 (254)

11 (279)

12 (305)

13 (330)

14 (356)

15 (381)

6.9 (113)

8.2 (134)

9.5 (156)

11.0 (180)

12.5 (205)

14.1 (231)

15.8 (259)

17.5 (287)

7.8 (128)

9.2 (151)

10.7 (175)

12.3 (202)

13.9 (228)

15.6 (256)

17.5 (287)

19.3 (316)

8.8 (144)

10.3 (169)

11.9 (195)

13.6 (223)

15.3 (251)

17.2 (282)

19.1 (313)

21.2 (348)

9.7 (159)

11.4 (187)

13.1 (215)

14.9 (244)

16.8 (275)

18.8 (3.8)

20.8 (341)

23.0 (377)

THICKNESS 5/16 in (7.94 mm) THICKNESS 3/8 in (9.52 mm)

Fo

r

Reference

Only

Loading...

Loading...