SIDE SHIMMING OF BOOM SECTIONS 800D

7-16

Published 5-27-2018 Control # 039-06

before the chosen radius is reached or allows extension

beyond the chosen radius, adjustment is required. If the

system is activated before trip pressure is reached,

lower the load, remove acorn nut and loosen the locking

nut on the compensating pressure switch and turn the

setscrew clockwise to increase trip pressure.

5. When the gauge reaches trip pressure, turn the

setscrew counter-clockwise until the system solenoid is

deactivated and tighten the locking nut. Retract the

boom until the pilot pressure is reduced enough to

reactivate the system solenoid. The hydraulic capacity

alert indicator light will go out when the solenoid is

reactivated. Check the trip pressure setting by extending

the load until the chosen radius is reached. As the

chosen radius is reached, the system solenoid should

be deactivated and the indicator light should come on.

Readjust switch head if trip pressure is not correct.

6. Once proper adjustment is verified, return the boom to a

firmly supported position, stop the truck engine and

replace covers.

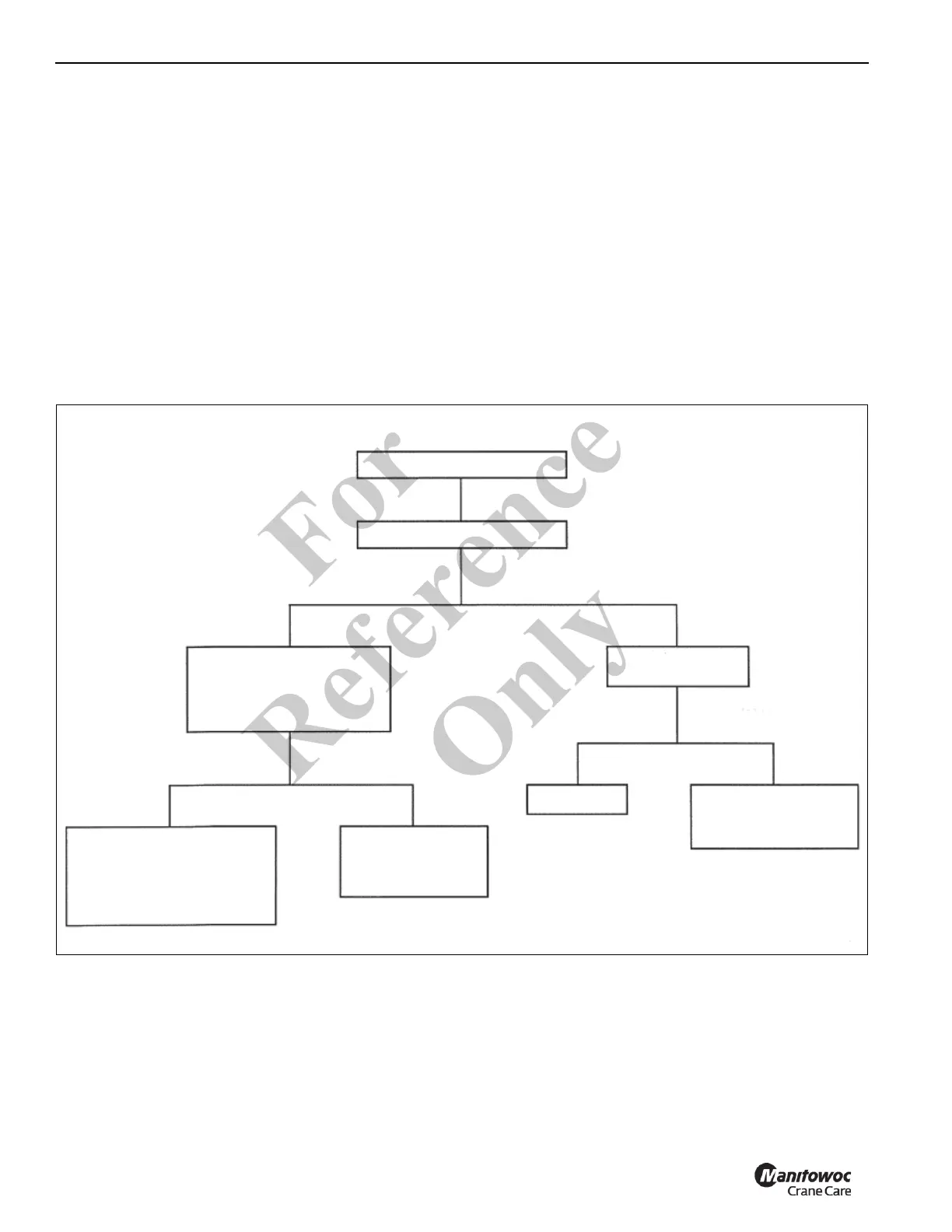

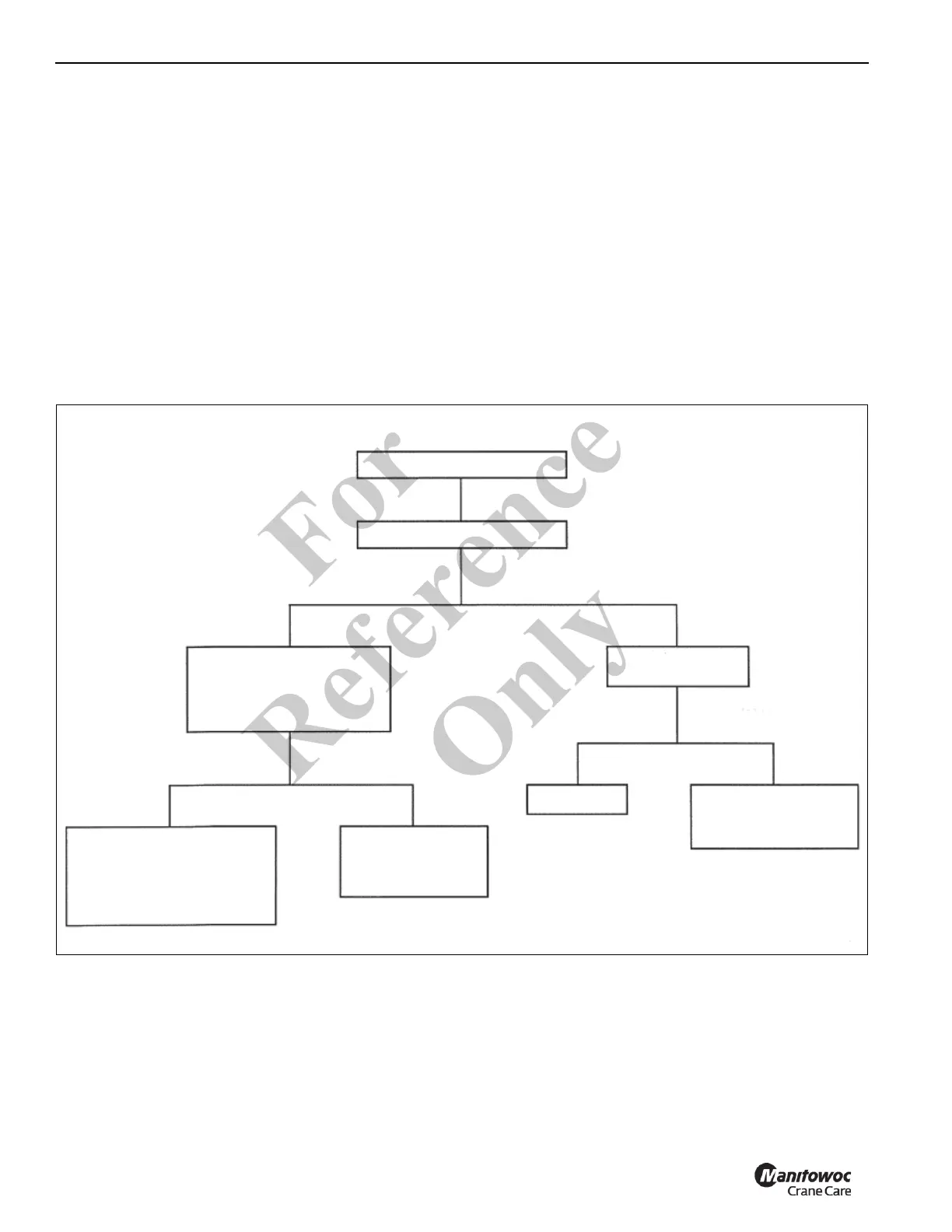

TROUBLESHOOTING

The following step-by-step analysis will be helpful in isolating

and correcting almost every service problem if followed in a

step-by-step systematic manner. Use this information with

the Hydraulic Schematic and the Illustrated Parts Catalog to

identify parts and follow flow paths. Start at top box and work

downward step by step - don’t try to start in the middle or skip

steps.

Boom Creeping Down

Control Valve Centered

YES NO

Cap Sensing Line Between

Counterbalance Valve and

Compensating Pressure

Switch

Control Valve in

Meter in Position

Control Valve in

Down Position

Normal Operation

Center Valve

YES NO

Replace

Compensating

Pressure Switch

Incorrect Counterbalance

Setting

Bad Counterbalance Valve

Leaking Cylinder Seals

Still Creeps Stops Creep

9423

Fo

r

Reference

Only

Loading...

Loading...