National Crane Published 5-27-2018 Control # 039-06 2-11

800D OPERATION

2. When Lifting Over the Front of the Truck and the Vehicle

is Equipped with a Front Stabilizer

A front stabilizer is required when loads are to be lifted

over the front of the vehicle. Before conducting any

boom operations, extend both outriggers until the

chassis weight is removed from the wheels. Level the

crane side-to-side using the level indicator located at

either control station as a reference. Then extend and

lower the rear stabilizers to level the crane front-to-

back. Again refer to the level indicator to insure that the

crane is properly leveled. After the crane is leveled side-

to-side and front-to-back, extend the front stabilizer

leg(s) until firm contact is made with the ground. Always

keep the load as close to the ground as possible.

3. Rear Mount Units Equipped with Rear Stabilizer A rear

stabilizer is required when loads are to be lifted over the

rear of the vehicle. Before conducting any boom

operations, extend both outriggers until the chassis

weight is removed from the wheels. Level the crane

side-to-side using the level indicator located at either

control station as a reference. Then extend and lower

the HO outriggers to level the crane front-to-back. Again

refer to the level indicator to insure that the crane is

properly leveled. After the crane is leveled side-to-side

and front-to-back, extend the rear stabilizer leg until firm

contact is made with the ground. Always keep the load

as close to the ground as possible.

Do not operate outrigger beams or legs unless they are

visible to either the operator or a designated signal

person to avoid crushing injury.

4. Check to ensure that the jib, if so equipped, is stowed

correctly on the first section boom.

BEFORE MAKING THE LIFT

1. Check all controls for proper operation by operating

each system through one complete cycle. This is

particularly important after the unit has been serviced or

repaired. If any abnormal operations are detected,

correct the condition before continuing.

2. During all operations, the controls should be metered

when beginning or terminating a movement to prevent

sudden starting or stopping which imposes undue shock

loads on the equipment. This metering can be

performed by metering the control lever and the foot

throttle.

3. Check the operating area for electric powerlines.

READING AND UNDERSTANDING THE

LOAD CHARTS

The structures and components of your unit are designed to

provide satisfactory service if the unit is not loaded in excess

of the maximum rated loads specified on the load chart.

Overloading can create serious potential safety hazards and

can also shorten the service life of your unit. It is important

that you know the weight and radius of any load that you are

attempting to handle. This should be done by use of a

dynamometer and tape measure or by contacting your

supervisor.

Overloading a crane can

cause many types of failure

depending on the

configuration and working

position of the crane, i.e.

structural damage to almost

any part of the crane hoist or

cable failure and tipping the

unit over.

The load chart shows the maximum rated loads including

load (weight being lifted), load handling equipment such as

slings, buckets, and downhaul weights, etc. which can be

handled by the crane and the hoist. The weight of the load

handling equipment and boom attachments must be

deducted from the maximum load rating shown on the load

chart to determine the payload which can be lifted. Additional

reduction may be necessary to make allowance for such

factors as the effects of freely swinging loads, wind, ground

conditions, out-of-level conditions and operating speeds.

The ratings shown on the outrigger full span load chart are

maximum loads and are based on the structural integrity of

the crane in shaded areas, the stability of the crane in

nonshaded areas. The stability or non shaded areas

represent a stability tipping factor of 85% when:

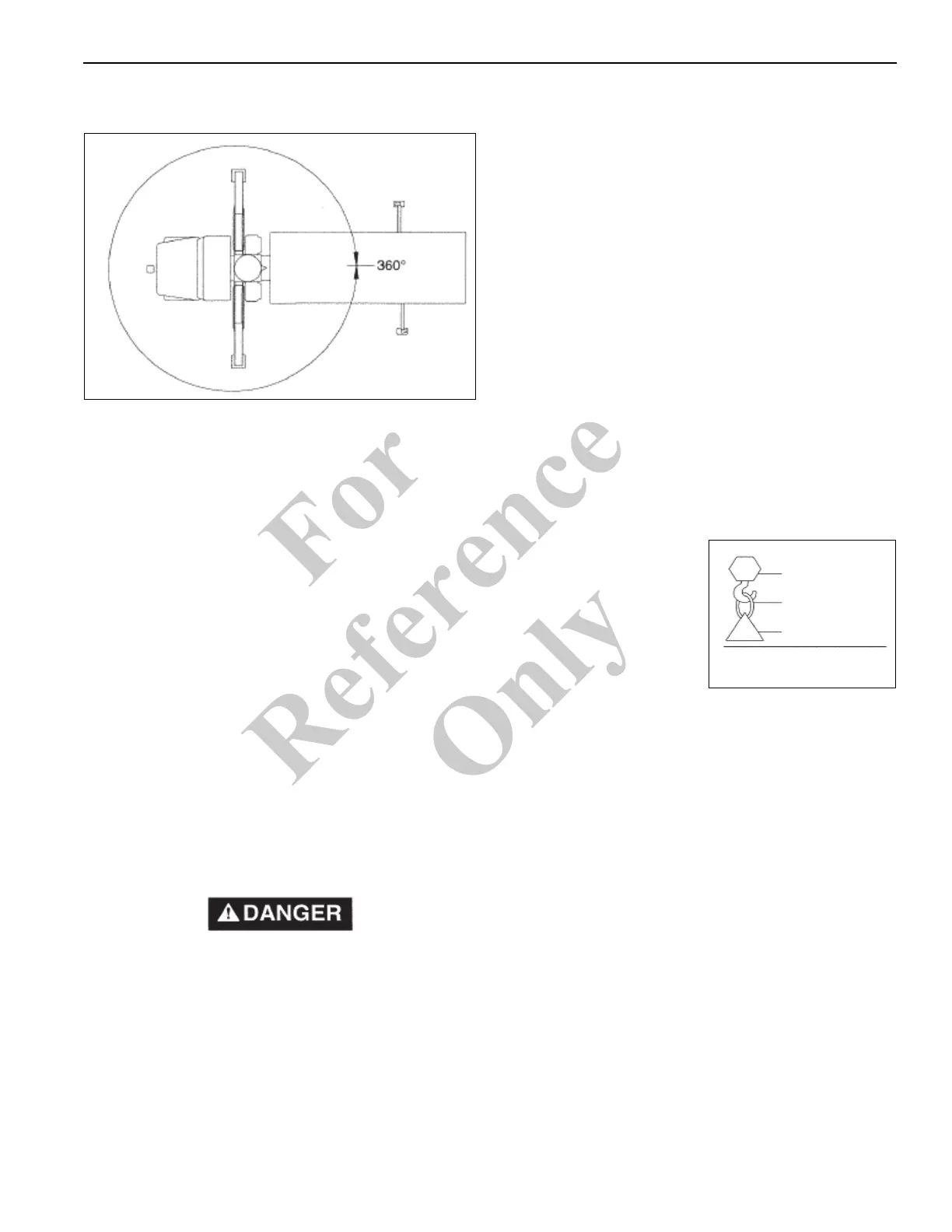

1. All outriggers are extended with positive contact on firm,

level surface, the tires are free of the ground and the

machine is level within 1°.

2. The proper amount of counterweight has been installed,

if required.

3. The unit is mounted in accordance with factory

instructions on a vehicle with proper specifications.

BLOCK

SLINGS

+

LOAD

+

TOTAL RATED LOADS

9348

Fo

r

Reference

Only

Loading...

Loading...