SIDE SHIMMING OF BOOM SECTIONS 800D

7-14

Published 5-27-2018 Control # 039-06

1. Disconnect the hose from one of the outrigger sections

and plug the port. This function can be used to test the

system pressure without the hoses or cylinder seeing

the higher pressure.

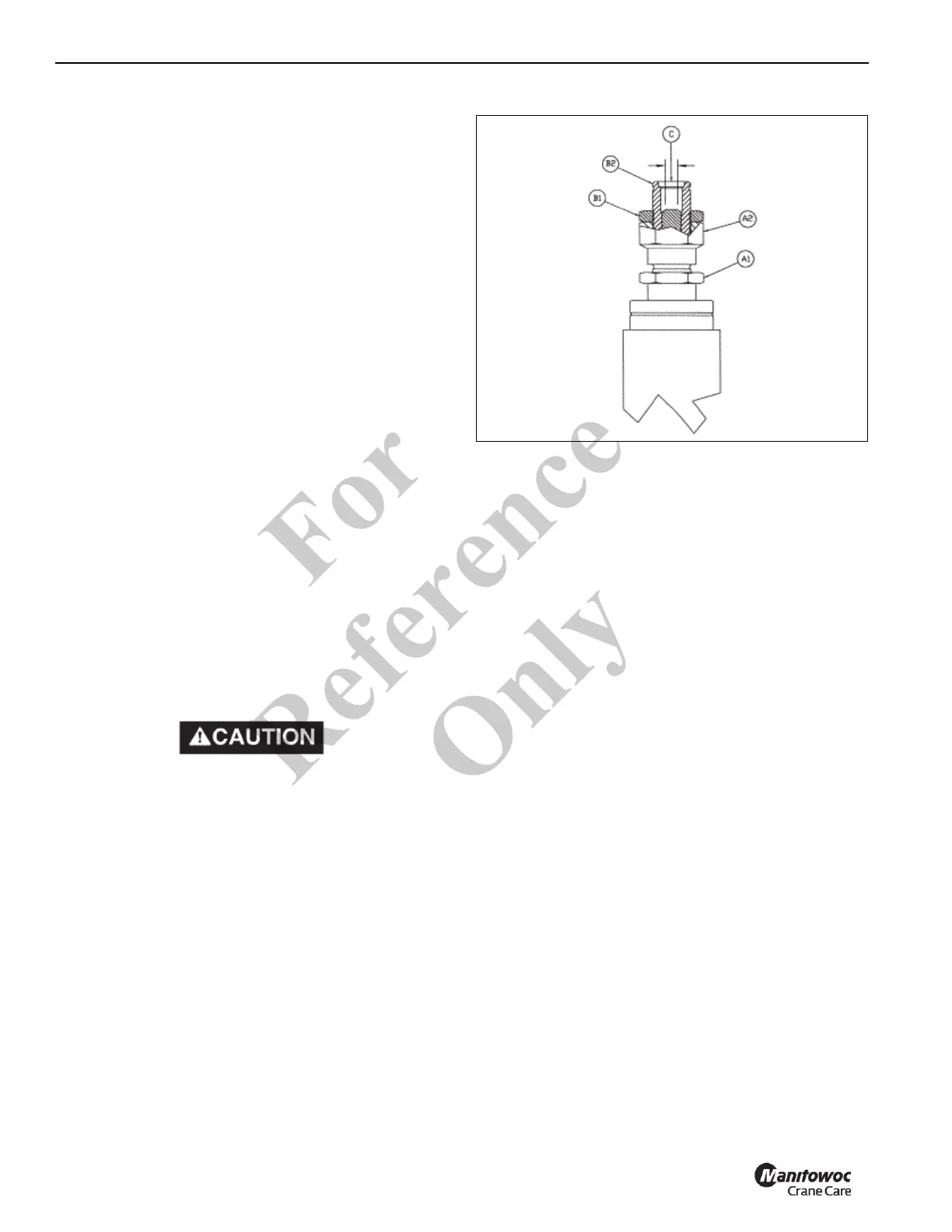

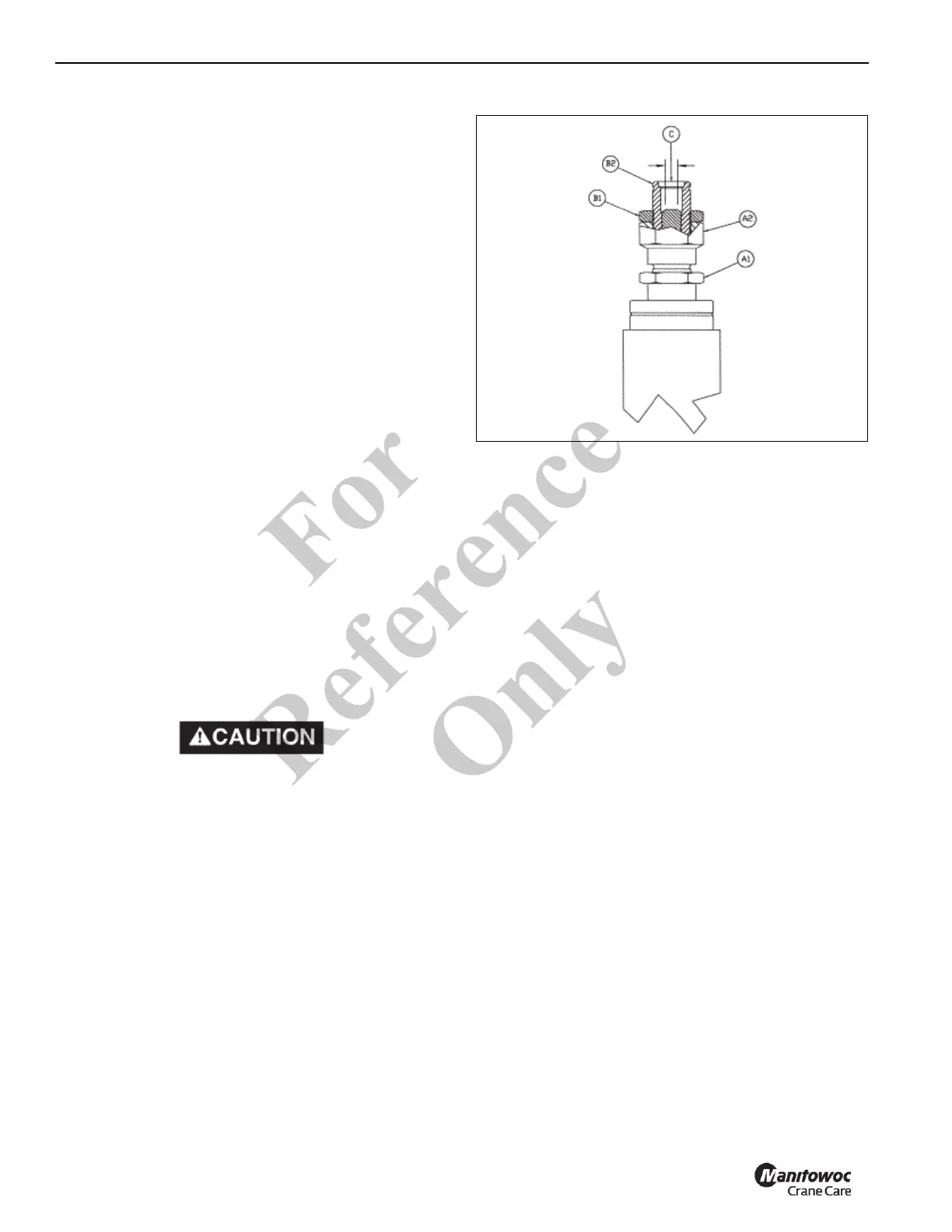

2. Remove the fitting from the relief valve at C.

3. Insert a plug with a diameter of 0.31 in (7.9 mm) and a

length of 0.31 in (7.9 mm) in the cavity at C.

4. Screw a SAE -4 fitting into the port at C until it is tight.

5. Loosen jam nut B1 and with a wrench on the two wrench

flats at B2 either screw the threaded body in or out.

Screwing the body in increases the pressure setting.

Screwing the body out reduces the pressure setting. The

pressure can be read on the gauge on the console

during adjustment. Correct pressure is listed above.

6. Once the correct pressure is attained, tighten jam nut B1

while holding the body with the wrench at B2.

7. Recheck the pressure on the console gauge to ensure

that tightening the jam nut has not changed the pressure

setting. Never set pressure above recommendations.

8. Remove the SAE -4 fitting and plug from location C.

9. Reattach the hydraulic line at C and check for leaks.

10. Reconnect hose to outrigger function.

Some valve sections include work port reliefs. The work port

reliefs are shim adjustable. Adjustment is made by adding or

taking out shims. Adding a 0.010 shim will increase pressure

100 psi (0.68 MPa). See “Specifications” section for correct

pressure settings. Never set pressure above

recommendations.

If the machine does not perform properly at these

pressures, the problem is not the relief valve and no

attempt should be made to readjust the setting. If the

relief valves are set to higher pressures than those

listed above, the warranty on the machine is void. Also

the machine could operate in a manner such as to

endanger personnel safety.

UNLOADER DUMP VALVE – AIR PURGING

INSTRUCTION

When a crane sits for a long period, the oil can drain back to

the reservoir and air could get into the pilot lines of the

unloader dump valves. This is likely to be more of a problem

in colder weather as the oil will not flow back into the

unloaders as easily when the crane is started. If the unloader

pilot tubes have air in them, the dump functions will not work

correctly. They might appear to be dumping the flow even

though the ATB or overload switch has not been tripped. If

this is suspected when checking the systems during start-up,

first try to purge any air that may be in the system.

Purposely trip the ATB switch to open the dump solenoid.

Engage each function that is being dumped (telescope out,

hoist up, and boom down) separately at full throttle for about

a minute, longer if the oil is cold. Then engage all three

simultaneously. Remove the two-block condition and check

performance of each function. If there is no change, the

procedure may be repeated. If again there is no

improvement, follow the troubleshooting steps outlined for

checking and inspecting the ATB solenoid and work port

unloaders.

HYDRAULIC SYSTEM DESCRIPTION

The hydraulic system of this machine is an open center type

consisting of a fixed displacement three section high

pressure pump which supplies oil to a main control valve and

a hoist control valve. The main control valve is equipped with

a main inlet and a mid inlet. The main inlet supplies oil to the

turn function, the mid inlet supplies the remainder of the

crane function requirements. The main control valves

contain inlet section reliefs or port reliefs which limit pressure

in the hydraulic system to acceptable levels and control

Fo

r

Reference

Only

Loading...

Loading...