REPAIR 800D

6-2

Published 5-27-2018 Control # 039-06

CYLINDER DISASSEMBLY AND REPAIR

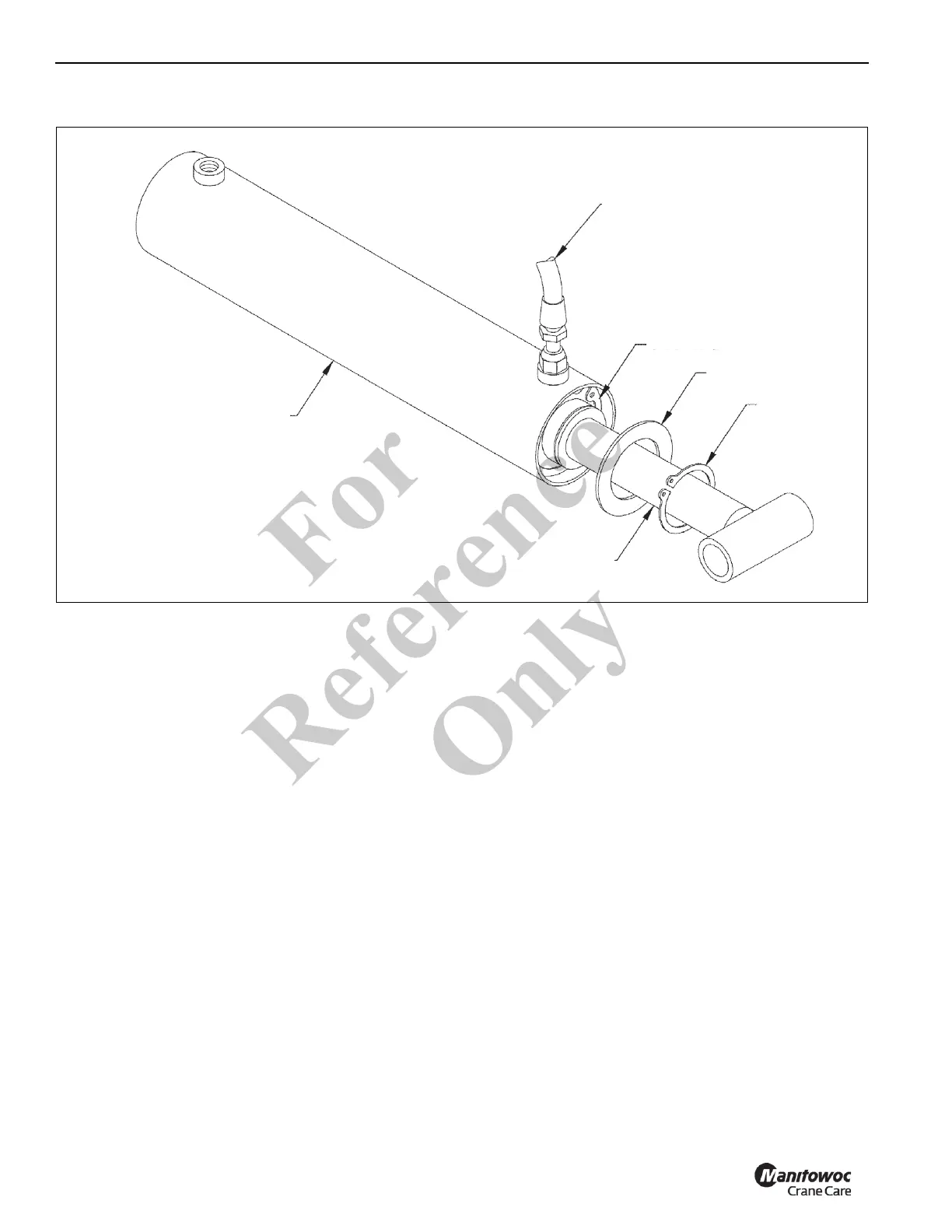

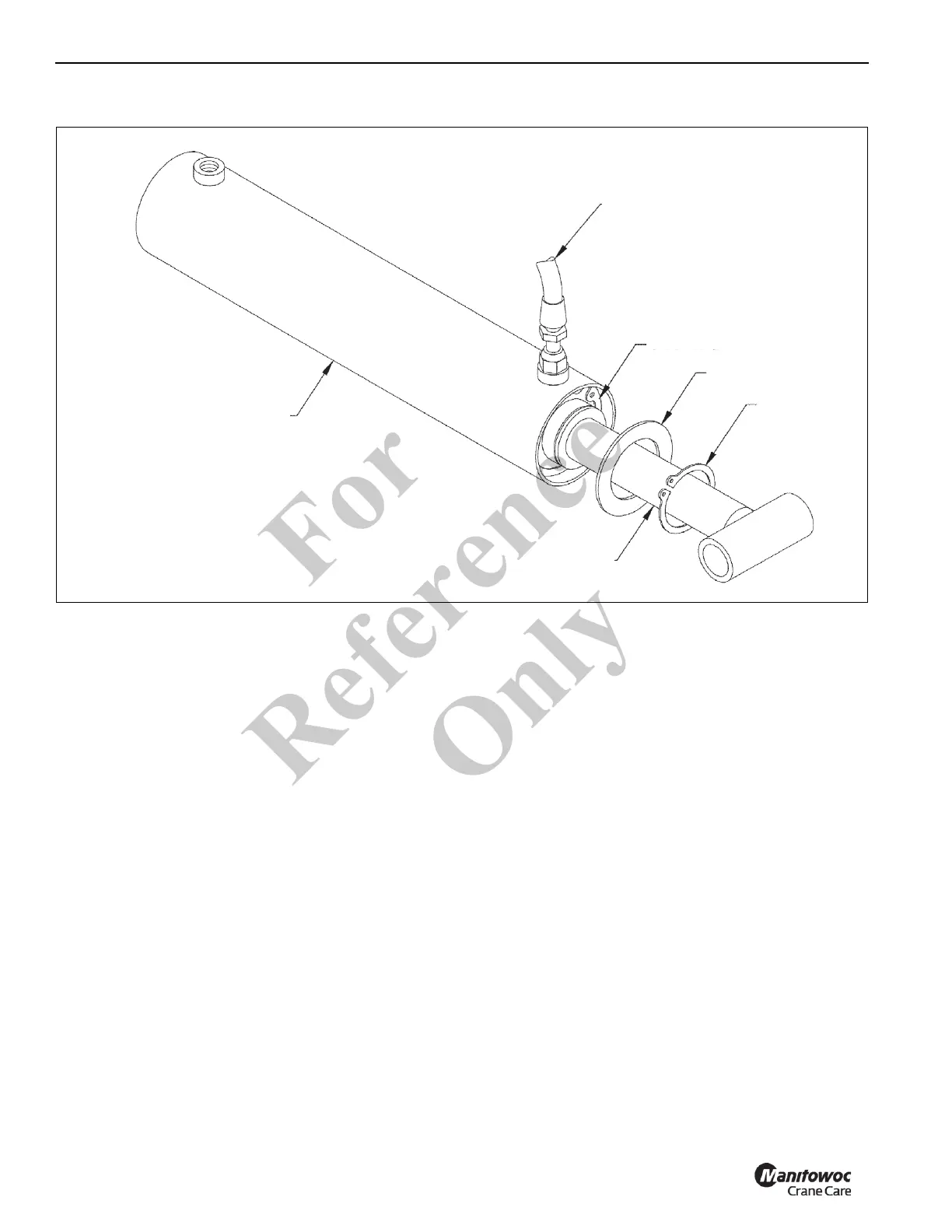

1. Disconnect shaft end of cylinder from machine.

2. Retract cylinder shaft with oil from the hydraulic system

until about 12 in (30 cm) of shaft is extended. The barrel

must be filled with oil to prevent a compressed air

chamber being formed which could result in injury at

disassembly.

3. Remove the cylinder from the machine and place on

supports with an oil pan directly beneath the cylinder

head area.

4. Using the proper size of internal snap ring pliers,

compress the snap ring completely and remove from

groove.

5. Attach a porta power hand pump or hydraulic line from

crane circuit valve to the shaft end of the cylinder. Debur

snap ring groove edge. Failure to do so will damage

barrel or packing gland.

6. Operate hand pump or crane circuit valve, preferably the

boom telescope circuit, to force packing gland out of

barrel.

7. Remove the shaft and piston assembly by hand.

8. Disassemble the piston set by removing nut, replace

worn or damaged parts. Note: Loctite® 680 is used

during original assembly to secure nut to shaft. If

necessary, heat nut to 400-500°F (204-260°C) to

facilitate removal. If heat is necessary for removal,

discard nut and replace with new equivalent nut as well

as worn or damaged parts.

9. Wipe and inspect cylinder barrel for internal damage.

10. Wipe and inspect cylinder shaft for damage.

11. Remove shaft packing by removal of internal snap ring

from packing gland. If spiral rings are used, they will

have to be replaced each time they are removed.

Replace parts as required.

12. Lubricate piston head snap ring at O-ring seal area

removing all nicks that have been formed at the snap

ring area that would damage the O-ring before

installation.

13. Reassemble shaft and piston set assembly. Apply

Loctite® to nut and onto shaft using type 680 according

to Loctite® recommendations.

14. Reinstall shaft and head assembly being sure that snap

ring expands completely and properly into the snap ring

head groove.

PRESSURE LINE FROM PORTA-

POWER OR HYDRAULIC LINE FROM

CRANE CIRCUIT VALVE

READ PARAGRAPH 5 & 6 BEFORE

PERFORMING THIS STEP

SNAP RING

WASHER

SNAP RING

SHAFT EXTENDED

CYLINDER BARREL

Fo

r

Reference

Only

Loading...

Loading...