OPERATION 800D

2-22

Published 5-27-2018 Control # 039-06

7. With power on and stabilizer beam fully extended,

ensure LED (6, Figure 2-9) on proximity switch

illuminates. Retract stabilizer beam and ensure LED is

not illuminated.

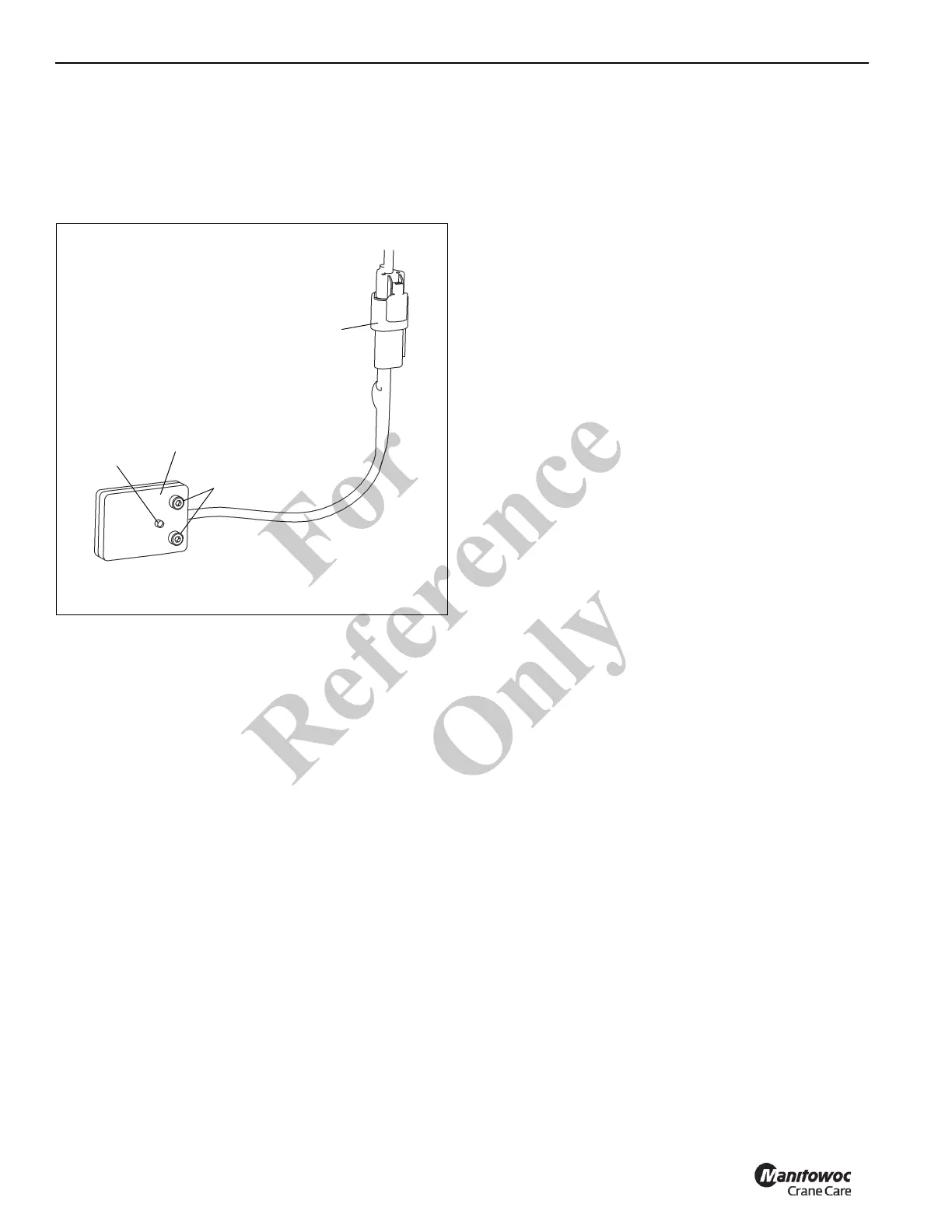

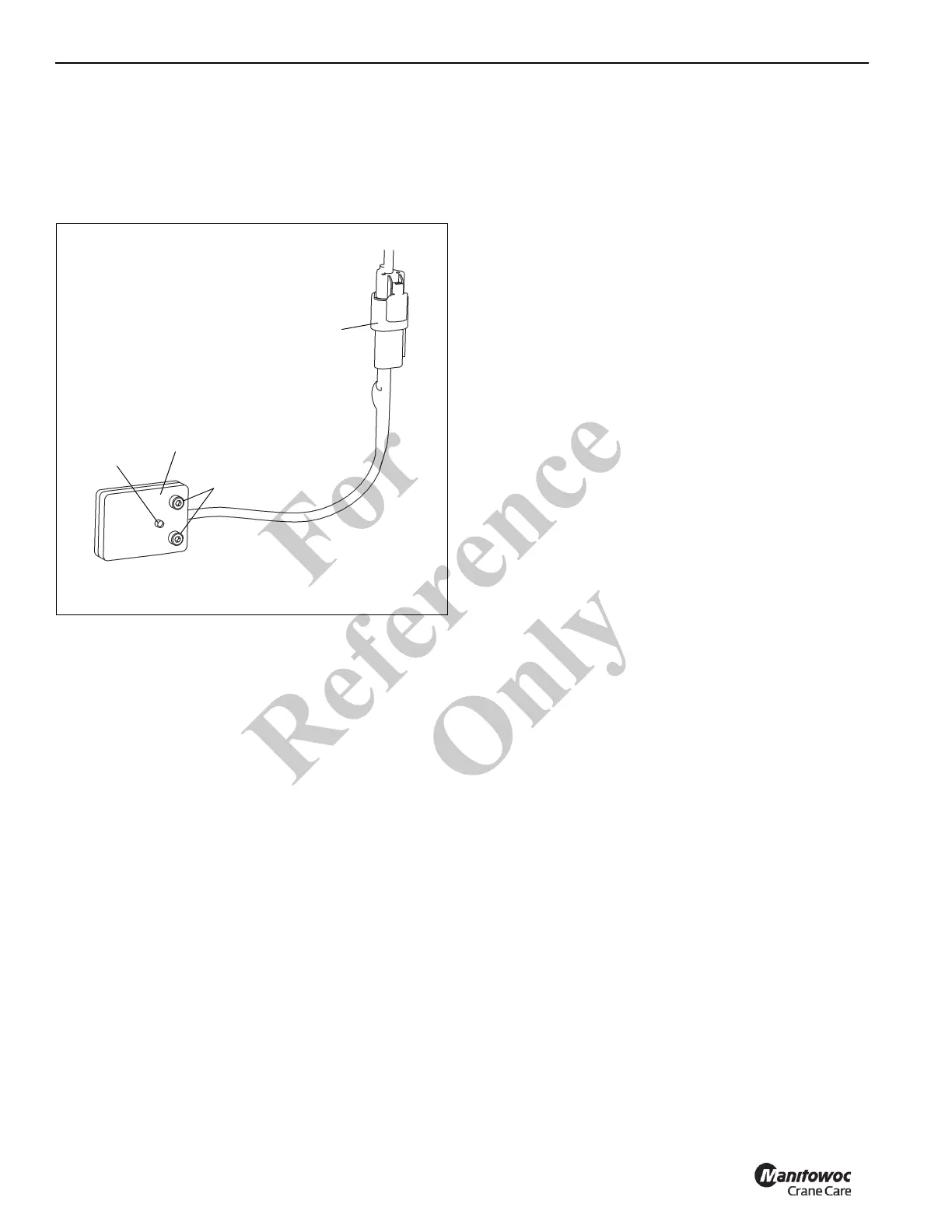

Stabilizer Proximity Switch (version 2)

Remove

1. Disconnect electrical connector (1, Figure 2-10) at

switch.

2. Remove the two screws (2, Figure 2-10) securing the

switch (4) to the stabilizer box. Remove switch.

Install

1. Fully extend stabilizer beam (horizontally).

2. Using two screws (2, Figure 2-10) secure the switch (4)

to stabilizer box.

3. Connect electrical connector (1, Figure 2-10) to switch.

4. With power on and stabilizer beam fully extended,

ensure LED (3, Figure 2-10) on proximity switch

illuminates. Retract stabilizer beam and ensure LED is

not illuminated.

ANTI-TWO BLOCK SYSTEM

Description/Operation

With untrained or inexperienced or distracted operators, two

blocking the hoist cable is a very real possibility. When the

hoist cable and end attachments contact the underside of the

sheave case, whether by hoisting up or extending the boom

without paying out the hoist cable, the hoist cable can be

damaged by crimping or over tensioning.

The anti-two-block system provided on your National Crane

can help prevent cable damage by sensing the position of

the hoist cable end attachments with respect to the sheave

case and disabling the functions that can cause a two block

condition.

The anti-two-block system consists of normally open, work

port unloader valves in the main and hoist control valves.

When the cartridge solenoid is energized, the crane

functions normally, when de-energized, the oil to the boom

extend, boom down, and hoist up crane functions are

diverted to tank. These solenoids are controlled by a limit

switch, which is attached to the boom or jib sheave case.

This switch is held in the closed position by a chain

suspended weight. The weight, which is looped around the

hoist cable, causes the contacts to remain closed until the

hoist cable end attachments contact the weight and release

the tension on the switch. At this point the contacts in the

switch open, breaking electrical continuity through the circuit

provided by the internal anti-two-block cord routed with a reel

or through the boom. When this continuity is broken, the

unloader cartridges de-energize and divert the function oil to

tank.

An audible and visual warning of the two block condition is

provided by the display console of the RCL system. See RCL

operators handbook for additional information.

If the machine is equipped with an optional Hydraulic

Capacity Alert (HCA) system, an indicator light provided on

the console will alert the operator when a two block condition

is detected.

Normal functioning is restored by hoisting down (or retracting

boom) until the weight is once again suspended freely.

Occasionally if the hoist up and boom extend functions are

operated at maximum speed in the dump mode, the back

pressure induced in the circuit will cause the hoist up or

boom extend functions to creep slightly (with no load on the

hook). Such a condition is not cause for alarm, as the back

pressure is not of sufficient magnitude to damage the cable

or end connections.

Fo

r

Reference

Only

Loading...

Loading...