McHale C430/C460/C470/C490 Bale Chopper

45

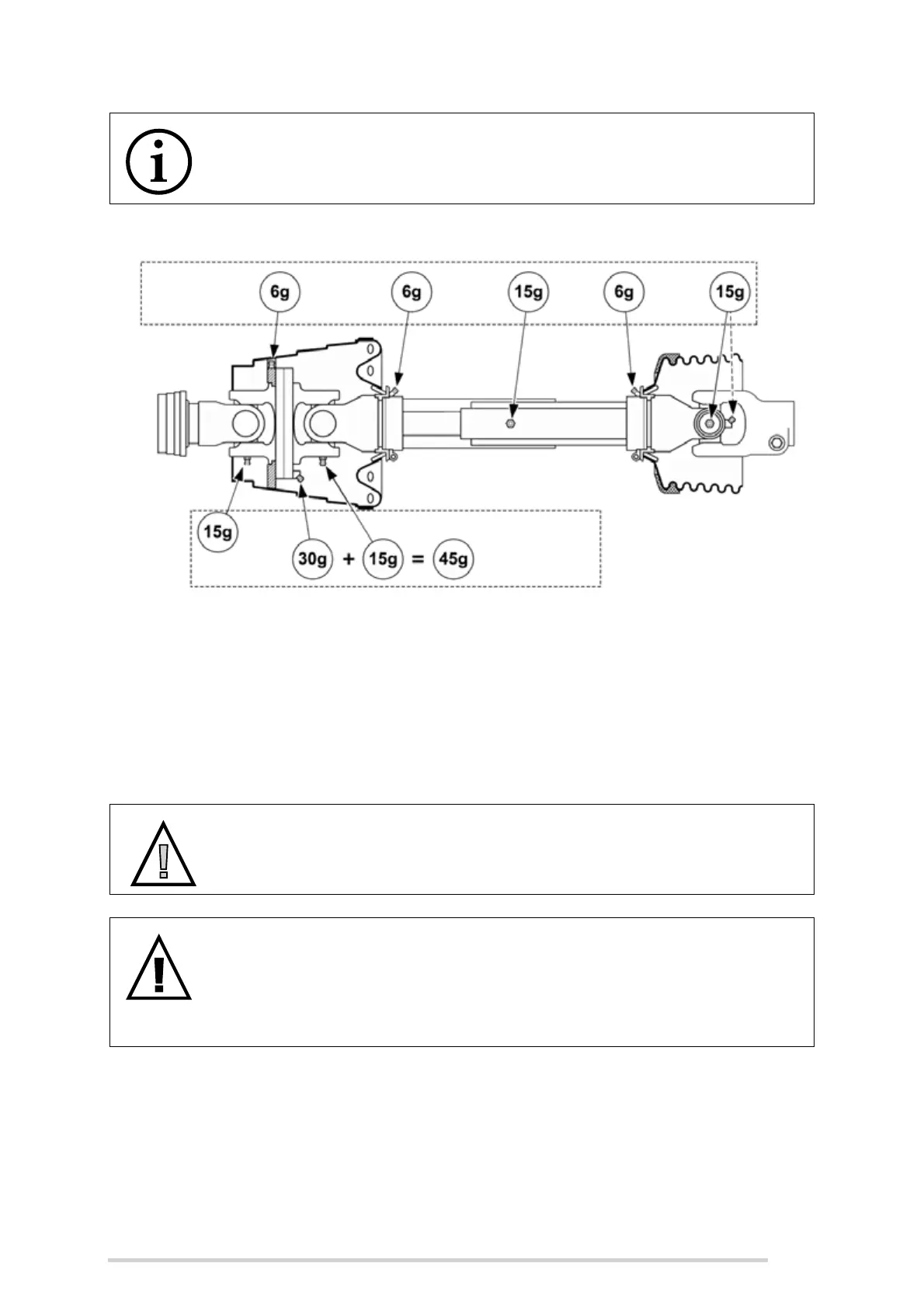

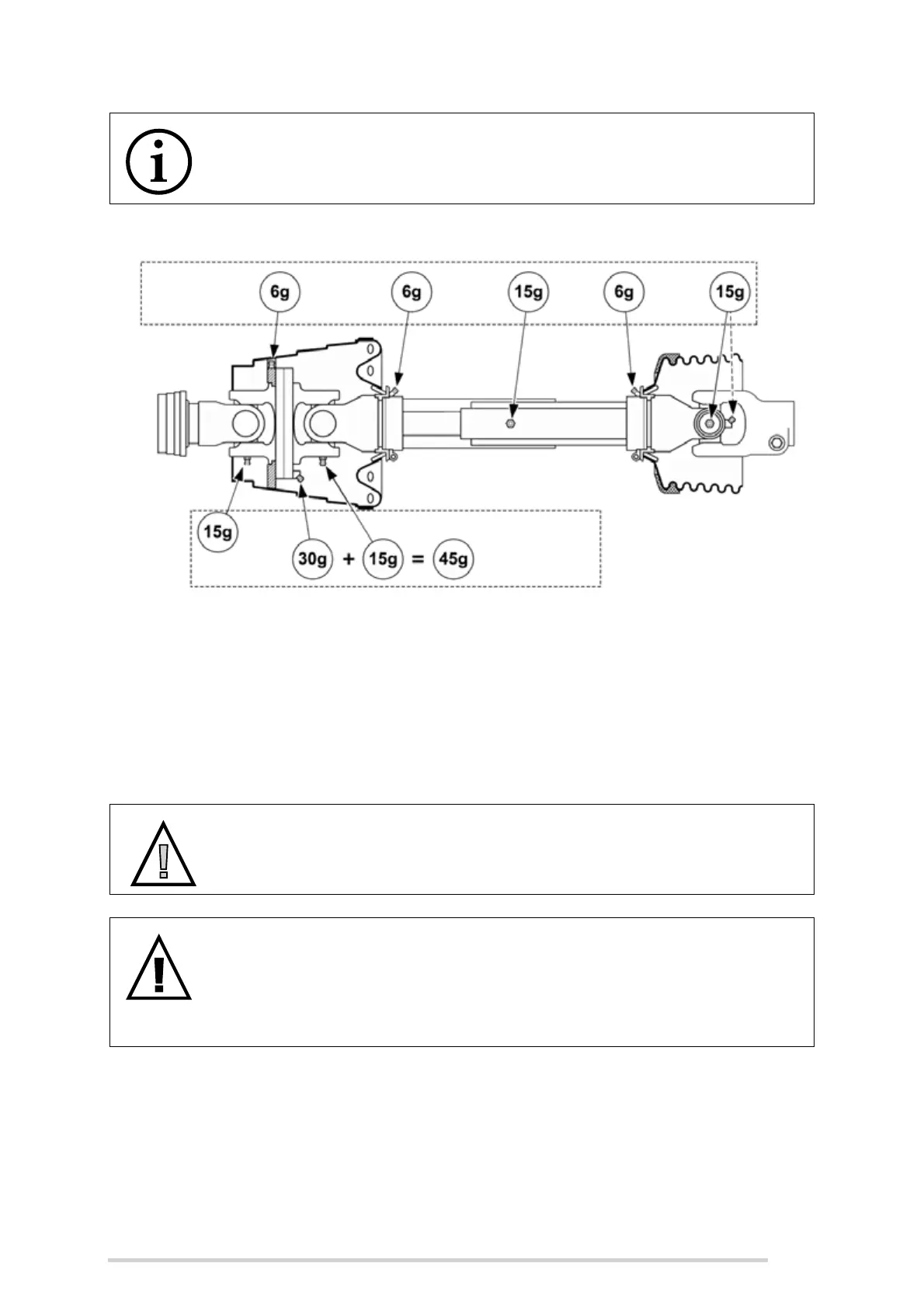

The recommended quantities of grease in grams for each grease point are shown.

For the C430 linkage machine, the PTO shaft must be altered to suit the tractor

combination it's being fitted to. After measuring carefully, the PTO shaft halves should

be cut equally so that the PTO shaft assembly is kept as long as possible, whilst just

allowing enough room for its removal, when in a horizontal position. This will ensure

that a maximum overlap (ideally 200 mm minimum) is maintained, when extended, as

the machine is lowered fully. The angle of operation should never exceed 25°

misalignment, otherwise permanent damage will result. (See ‘Adjusting the PTO shaft

to the tractor’)

NOTE: Grease point intervals

The lower 3 PTO shaft grease points are to be greased at 8 hour

intervals. All other grease points are to be serviced at 60 hour intervals.

CAUTION: Ensure safety chains are attached to machine and tractor

Ensure the safety chains on the PTO cover sleeves are attached to both

machine and tractor to prevent them from spinning.

WARNING: Ensure PTO guarding is in good condition

Never use the machine if the PTO guarding is missing or damaged.

Entanglement in rotating drive line can cause serious injury or death.

Always stop the engine and ensure that driveline has stopped before

making connections, adjustments or cleaning out PTO driven equipment.

Grease at

60 hour

intervals

Grease at

8 hour

intervals

Loading...

Loading...