McHale Fusion Vario Baler & Wrapper

130

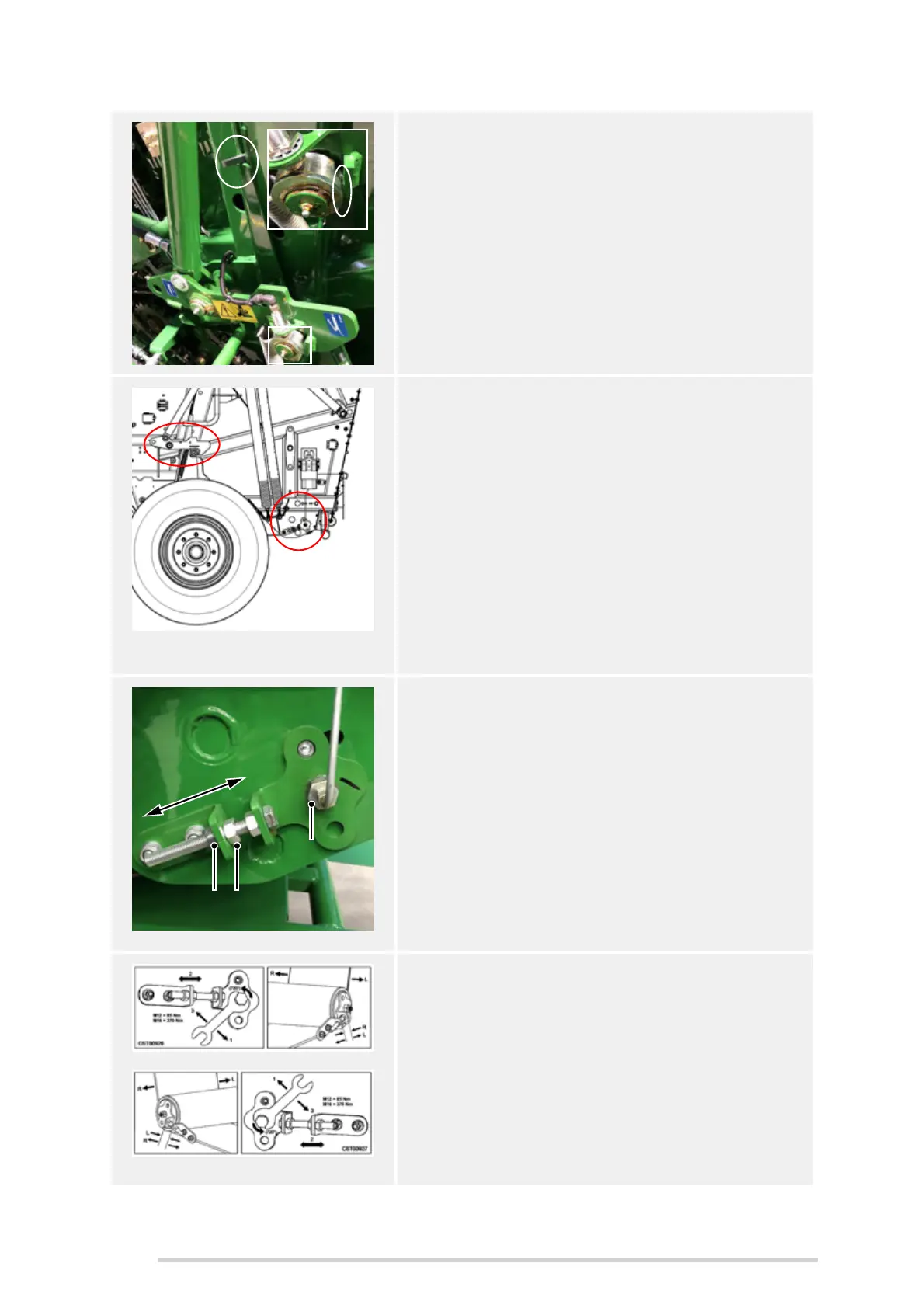

2. With the chamber door pressurised closed,

check that the door pin rollers are tight

against the door lock hooks. If not, then the

chamber door must be wedged back, until full

contact is established. A thin wedge can be

hammered into the gap, as shown, to ensure

the chamber door pin rollers are tight against

the door lock hooks. This should be repeated

on both sides as it simulates the working

conditions while baling.

3. Restart the tractor and run the machine.

Check the direction (right or left) in which the

belt(s) have moved. This is most clearly seen

on either the top tension arm roller or the

tracking roller itself. The belt(s) can be

aligned by adjusting the belt tracking roller

which is located at the lower back corner of

the tailgate.

WARNING: Before approaching the

machine, make sure that the tractor is shut

down, with the hand brake applied and the

ignition key removed.

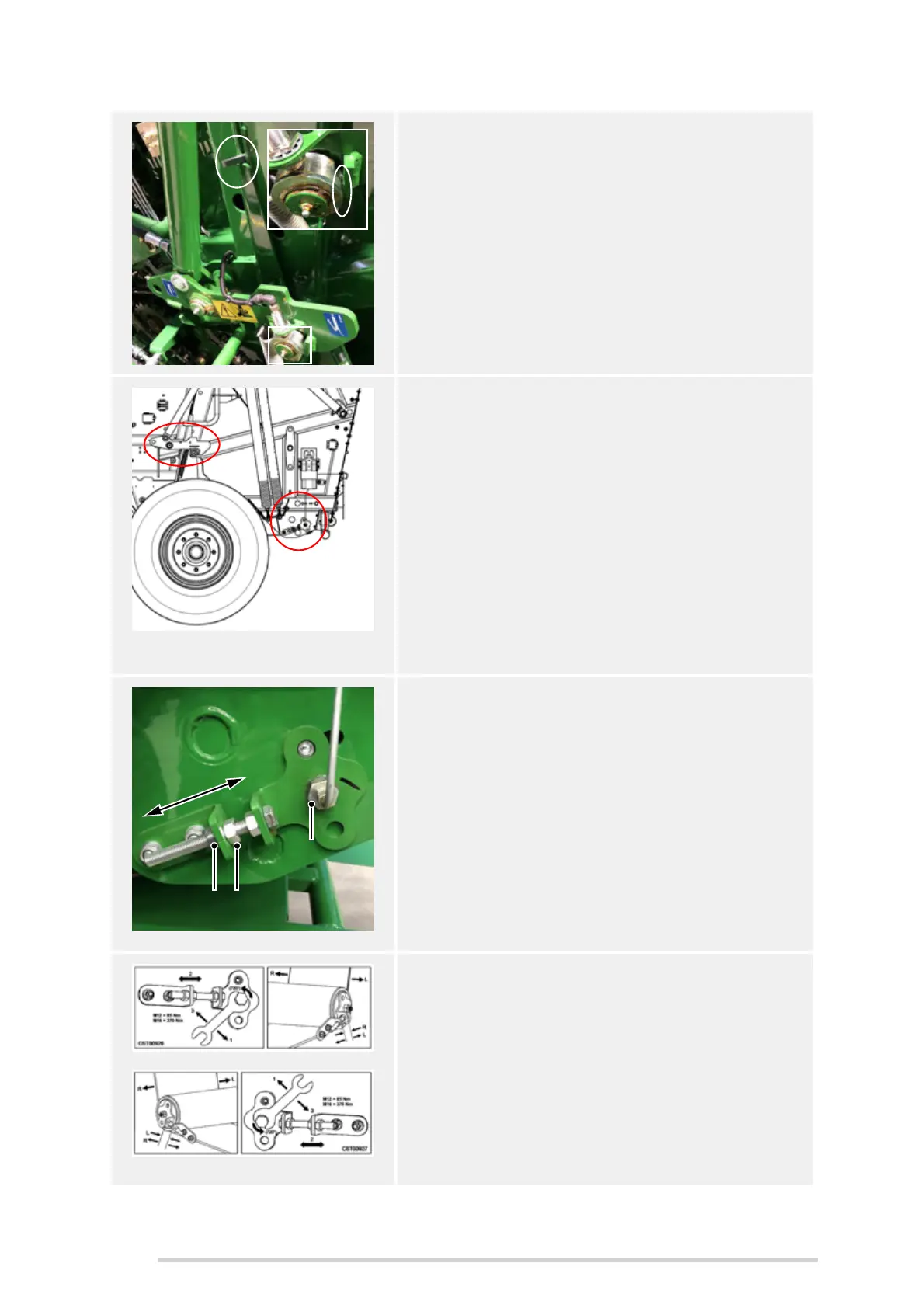

4. Adjustment should only be necessary on one

end of roller (i.e. either left or right-hand side).

First, the grease pipe fitting must be

disconnected from bolt (B).

Next, loosen bolt (B) using a 24 mm A/F

socket or spanner and back off just a few

millimetres (a maximum of 2 full turns)

Using a 19 mm open-end spanner, back off

locknuts (C & D), as shown.

5. By adjusting locknut (C or D), the roller centre

can be moved either rearwards (R) or

forwards (F). Moving the roller end forwards

will encourage the belt(s) away from the side

being adjusted and moving the roller end

rearwards will encourage the belt(s) towards

that side.

Make very fine adjustments as a very small

amount can make a noticeable difference.

Loading...

Loading...