38 TORKEL 900-SERIES ZP-CS01E CS033663DE

9 OPTIONAL EQUIPMENT

The other parts of the BVM system: AC Adapter, Power and

Signal Connector and cables.

Power & signal connector unit

The BVM units require external 24 DC power and RS-

485 data communications for operation. These func-

tions are provided by a combination of an external DC

power supply and a Power & signal connector unit”.

The Power & signal connector conversion is performed

within a single moulded plug that connects directly to

the laptop computer or other data acquisition device.

The Power & signal connector has an RJ-45 connector

that provides a connection to the first BVM unit in the

chain, and this connection provides RS-485 data and

power to all BVM units in the BVM string.

Test with BVM and TORKEL

WARNING

See the chapter "Safety" for safety pre-

cautions.

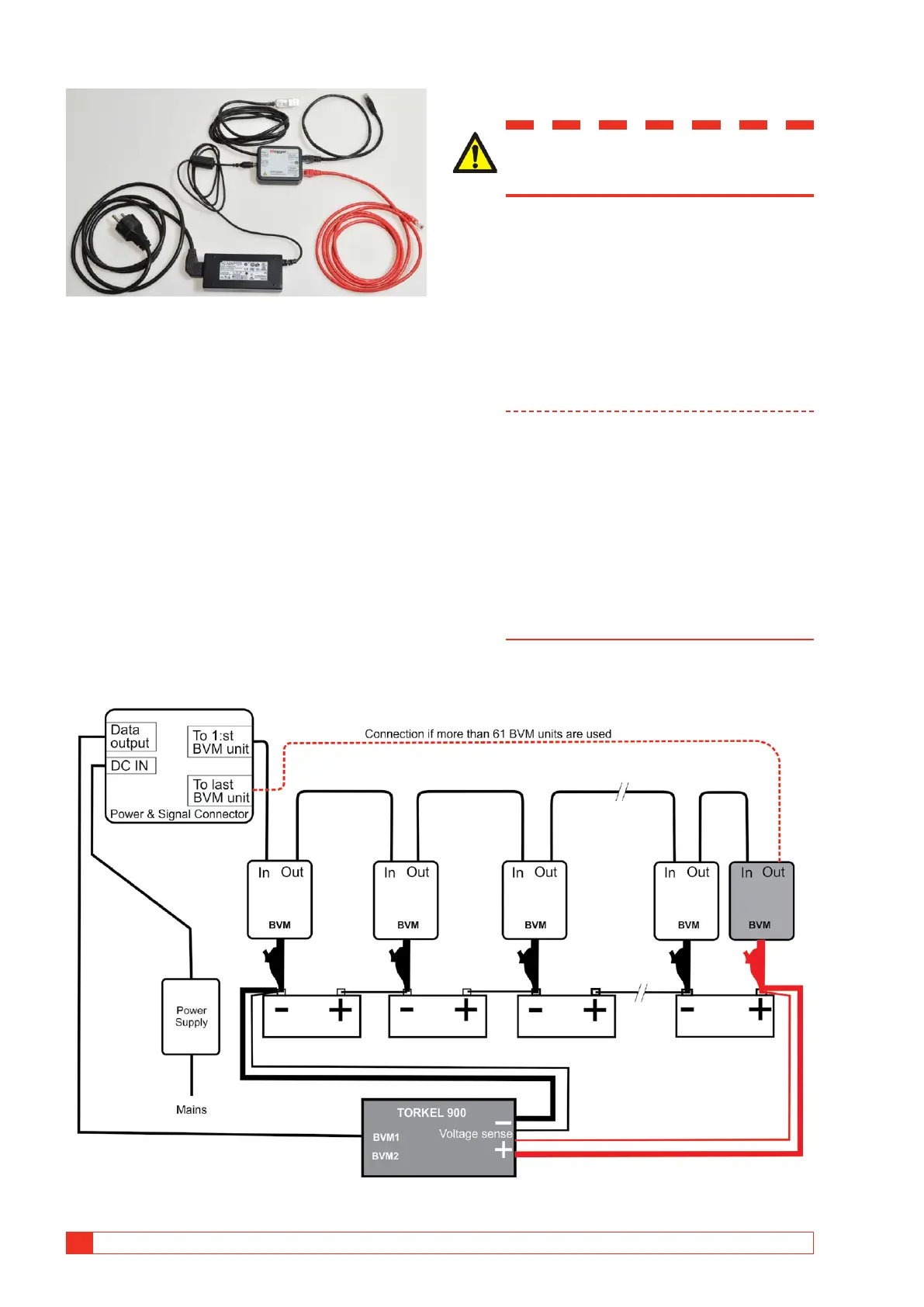

1] Connect the BVM units as shown in the con-

nection diagram, see below.

Each BVM is identical and can be connected

in any battery test position. Up to 120 BVMs

can be daisy-chained in a single battery bank

under test.

If you need more than 120 BVMs they must

be connected in two loops, see connection

diagram on next page.

Note The BVM units must be connected following

the battery cell sequence order. The BVM

connected to the “To 1:st BVM unit” port of

the Power and Signal connector must be con-

nected to the most Negative pole of the bat-

tery. The red dolphin clip shall be connected

to the most Positive pole of the battery. The

connection is the same regardless of the cell

numbering selected in TORKEL.

If more than 61 BVM units are connected

an extra cable is needed. See the connection

diagrams.

Fig.9.1 The BVM units must be connected following the battery cell sequence order. The red dolphin clip shall be connected

to the most Positive pole of the battery.

Loading...

Loading...