kajaaniMCA

i

– Installation, Operating & Service - 9.1 - W4610201 V2.5 EN

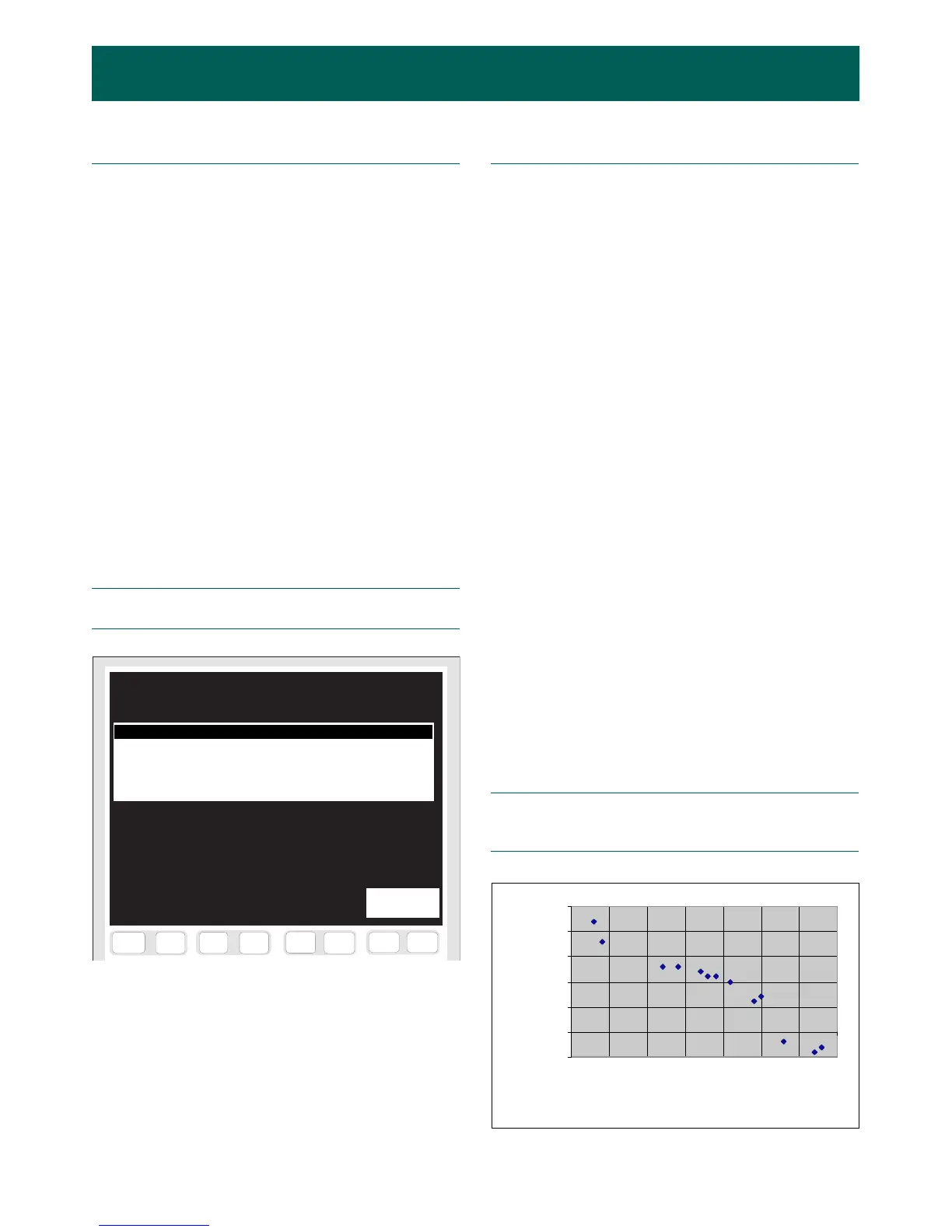

9. Special Functions

9.A. Special Functions

Go from M

AIN MENU => SELFDIAGNOSTICS => SPECIAL

FUNCTIONS

(Fig. 9.1).

The “Special functions” menu contains functions

for chemical content and temperature compensation,

filler content, sampling, recipes, and sensitivity coeffi-

cient.

• Chemicals compensation is needed if large varia-

tions occur in the chemicals content of the process.

• Temperature compensation can be applied to correct

the measurement, section by section, using a linear

curve. This correction is needed if the process

temperature may go below 30°C (86°F).

• The filler content information can be connected to

the sensor as an analog signal, the sampling infor-

mation as a binary signal.

• The recipe function can be used in cases when the

process conditions vary so much that one calibration

cannot cover the entire range.

• The sensitivity coefficient function can be applied to

change the Cs sensitivity of the MCAi sensor.

The last two functions are mainly needed in applica-

tions outside the pulp & paper industry.

NOTE: The last two functions are normally not visible in

the menu – to display them, press 0 (zero)!

9.B. Chemicals compensation

9.B.1. Principle

Large variations in the chemicals content of the pulp

affect the measurement of microwave propagation time.

As a result, the MCAi will show a too high reading

when the chemicals content increases. Chemicals also

affect the attenuation of the microwave signal, causing

a lower signal level result (u). Thus there is a correlation

between the consistency error (MCAi – Lab. value) and

the measured signal level. Based on this correlation, the

Cs measurement error caused by the chemicals content

can be eliminated by applying the correct chemicals

compensation factors.

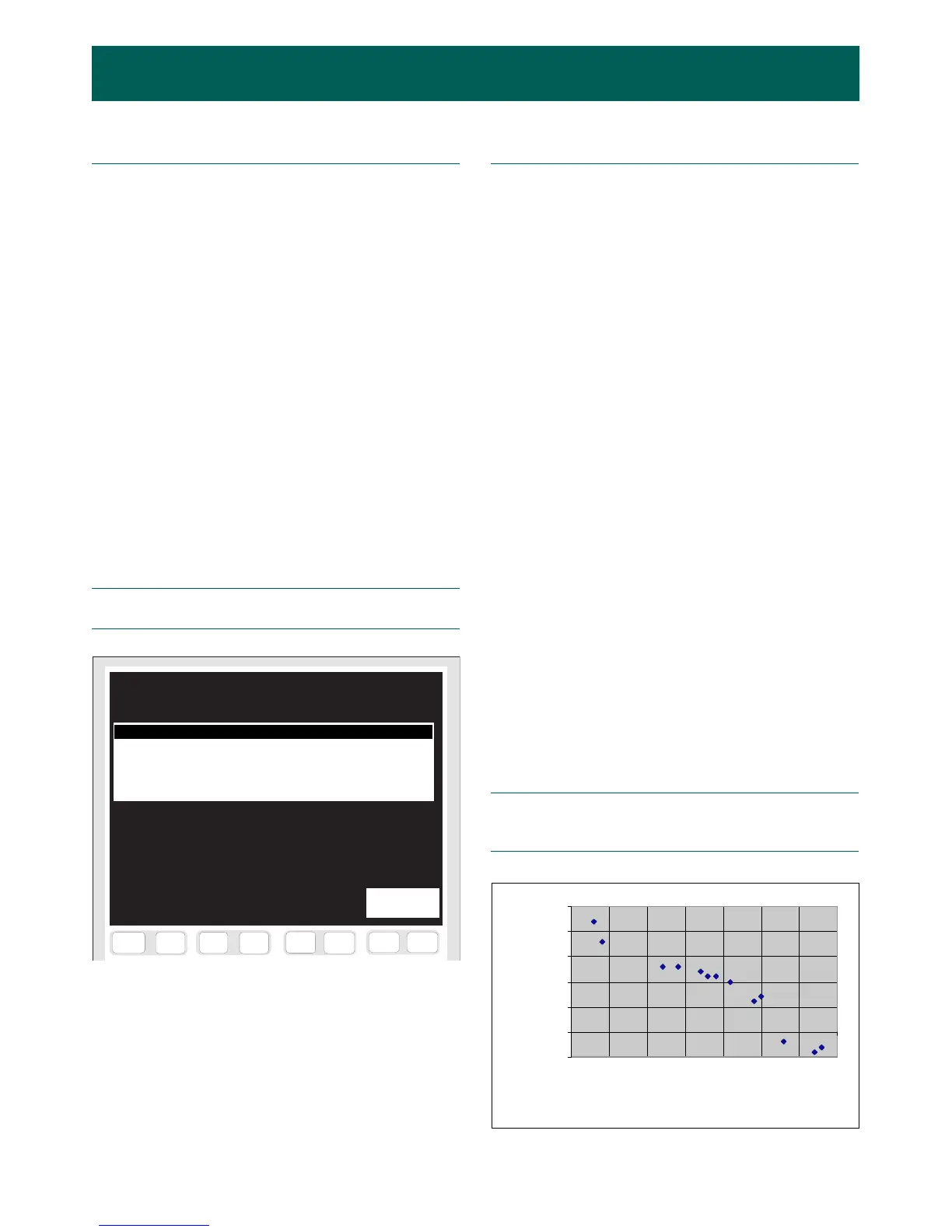

If large variations occur in the chemicals content of

the process, the consistency, signal level and tempera-

ture measured by the MCAi should be included in the

laboratory follow-up, as well as the conductivity and

consistency measured in laboratory. Based on the col-

lected data, the signal level measurement can be cor-

rected by chemicals compensation if needed. Fig. 9.2

shows an example graph based on laboratory follow-up

results; in the graph the consistency error (MCAi –

Lab.) is on the Y-axis, signal level on the X-axis. Mlev

is the abbreviation used for the MCAi signal level.

As the graph shows, the consistency error (MCAi –

Lab) correlates with the signal level. This indicates that

the error is caused by chemicals and thus it can be

eliminated by chemicals compensation. To make sure,

we can make a graph with conductivity (reflecting the

chemicals content) is on the X-axis. The graph should

then be a rising straight line; the error (MCAi – Lab.)

grows when conductivity increases.

Chemicals compensation is determined by means of

two-point calibration.

NOTE: Select the calibration points so that the differ-

ence between their chemicals contents and signal levels

is as great as possible.

F7

F6

F5

F4

F8

F3

F1

F2

F9

F10

F11

F12

F13

F14

F15 F16

i

Special functions

Chemical compensation

Temperature compensation curve

Filler contents: analog input

Sample taking: binary input

Recipes

Sensitivity coefficient

ENTER =

Open

Fig. 9.1. “Special functions” menu.

Fig. 9.2. Correlation of Cs error to signal level.

-0.05

0

0.05

0.1

0.15

0.2

0.25

35 40 45 50 55 60 65 70

Mlev (u)

MCAi - Lab (%)

Loading...

Loading...