kajaaniMCA

i

– Installation, Operating & Service - 11.1 - W4610201 V2.5 EN

11. Troubleshooting & Service

NOTE: Before detaching a sensor or the antenna of a

flow-through model, make sure that the process pipe-

line is empty and unpressurized, and that the work can

proceed safely!

The kajaaniMCAi does not require any regular main-

tenance. This chapter contains instructions for possible

fault situations.

11.A. Troubleshooting

The sensor contains a process measurement channel, an

internal reference channel, and a process temperature

measurement. All of these measurements are moni-

tored by the sensor’s self-diagnostics. When an error or

fault is detected, the self-diagnostics will give an error

message. However, it cannot precisely locate the unit or

module where the fault originated. To locate the origin

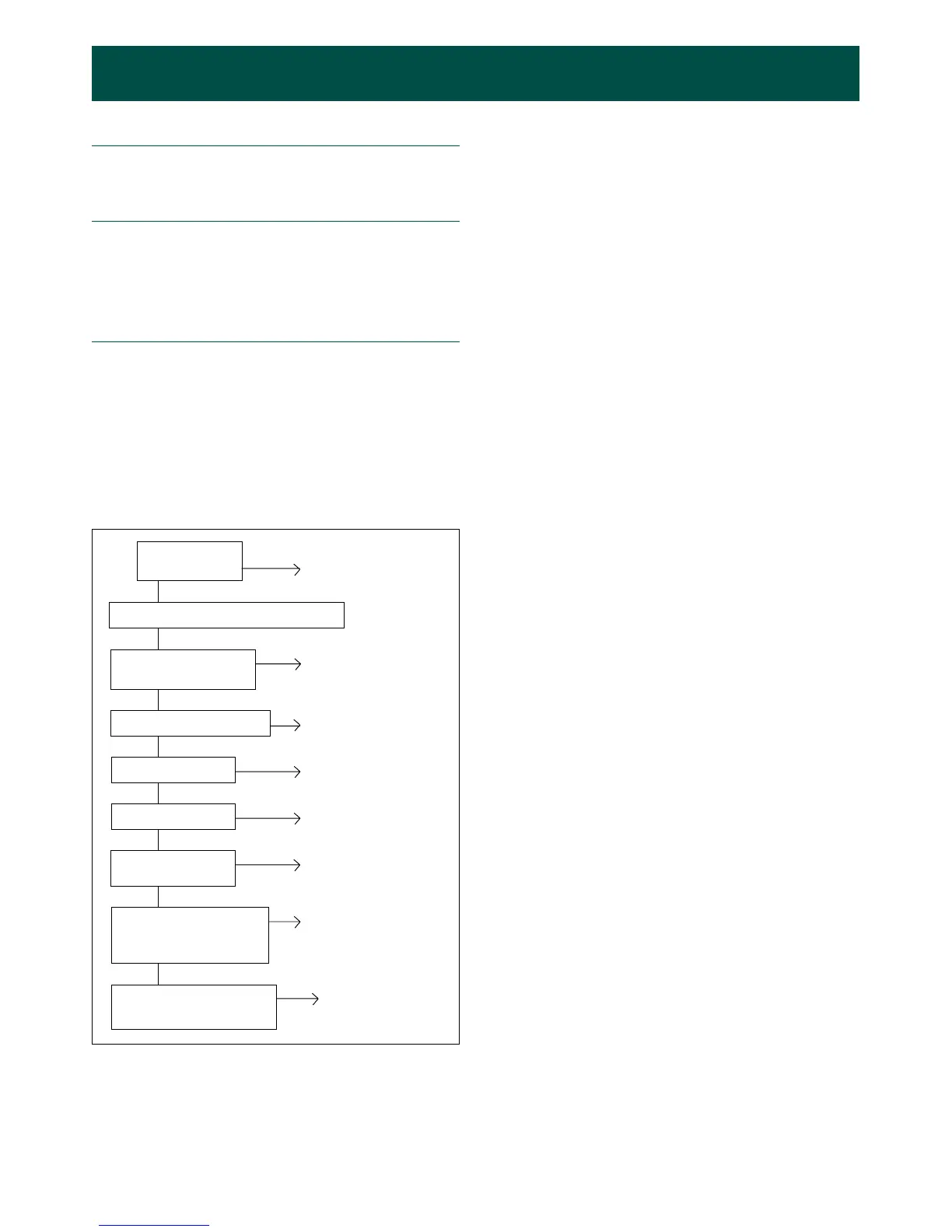

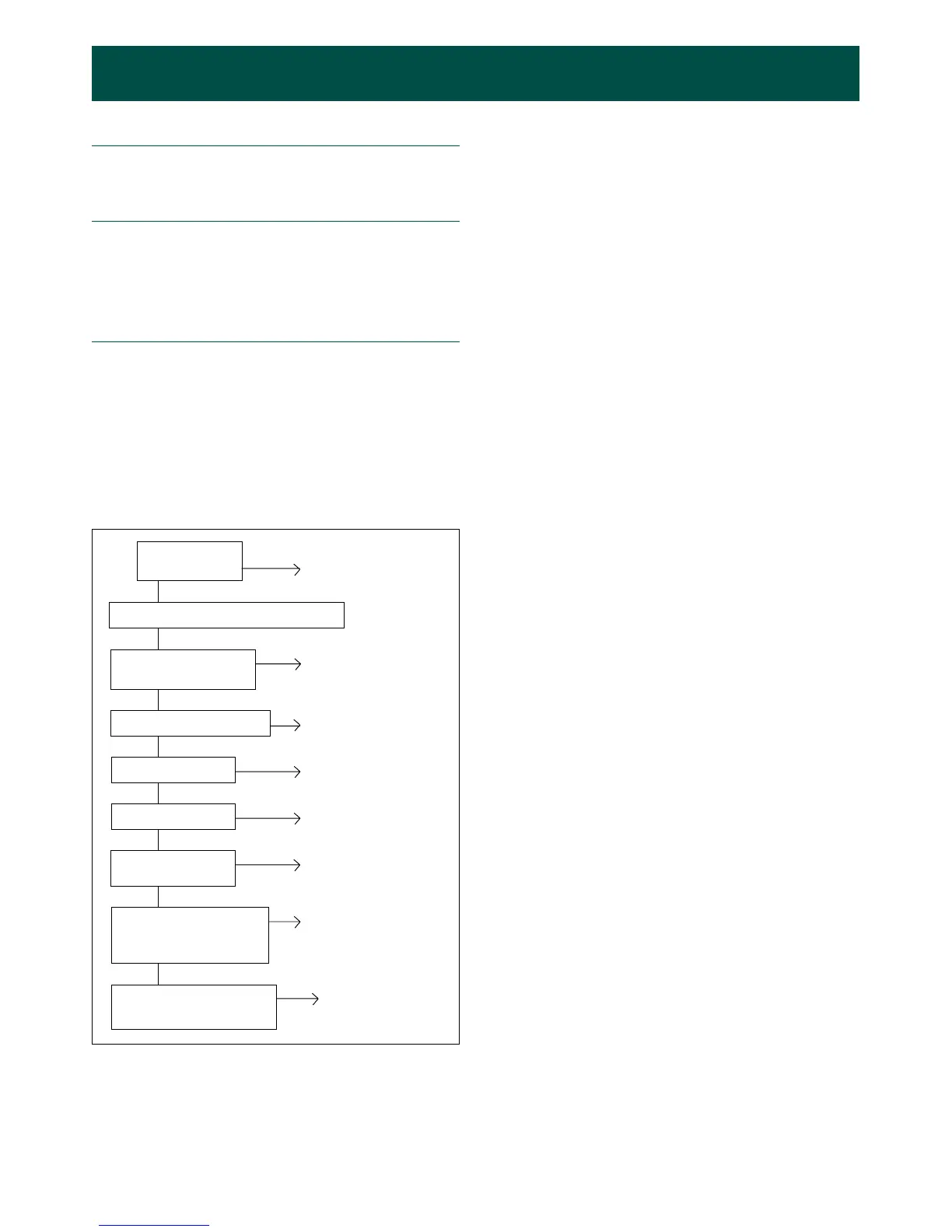

of a fault, follow the diagram shown in Fig. 11.1.

11.A.1. Chemicals content

Chemicals dissolved in the process attenuate the micro-

wave signal. A substantial increase in the chemicals

content may attenuate the signal level below the low

limit set for the self-diagnostics. The signal level can be

increased by performing a new start-up (section 6.A) at

the new, higher signal level.

Large variations in the chemicals content may also

cause error in the measurement, even if the signal level

stays within the operating range. In this case, use

chemicals compensation to eliminate the error; see

instructions in section 9.B or 12.C.1 (HART communi-

cator).

11.A.2. Temperature

Water temperature affects the propagation velocity of

microwaves. A substantial drop in process temperature

may attenuate the signal level below the low limit set for

the self-diagnostics. The signal level can be increased

by performing a new start-up (section 6.A) at the new,

higher signal level.

If the signal level stays within the correct operating

range but the measurement shows a temperature effect,

use temperature compensation to eliminate the error;

see instructions in section 8.C or 12.C.2 (HART com-

municator).

11.A.3. Air

Air in the process is a disturbing factor that increases the

consistency reading. To eliminate this, the minimum

process pressure specified for the MCAi is 1.5 bar (21.8

psi). At pressures above this limit the contained air is

dissolved in the water and thus will not disturb the

measurement.

Large air bubbles do not dissolve in water, and thus

it is not possible to give precise pressure specifications

for eliminating them. Large bubbles are generated e.g.

when pulp is dropped into a chest while the level is low,

and especially if pulp is dropped to the intake side of a

pump. The resulting air bubbles have no time to disap-

pear and they will pass into the pipelines. Also strong

agitation while the level in the chest or tank is low may

generate a whirl that sucks air into the stock. Another

source of air in the pulp are possibly leaking joints at the

intake side of a pump.

11.A.4. Leak in microwave antenna

This problem will appear as a slow drift of the measure-

ment signal to one direction, most likely downwards.

The signal level may also decrease slightly. If a leak is

detected, replace the antenna with its antenna cable. To

check an antenna for leaks, open the antenna cable

casing, at the antenna end, and see if it contains water.

Fig. 11.1. Troubleshooting diagram.

Reference

channel fault

See section 11.B.

Check the process conditions

No

Chemicals content/

conductivity?

See section 11.A.1

Process temperature?

See section 11.A.2

No

Air?

See section 11.A.3

No

Antenna leak?

See section 11.A.4

No

Antenna

contamination?

See section 11.A.5

No

Strings or other

material accumulating

on fork-type sensor?

See section 11.A.6

No

Measurement channel

fault in electronics?

See section 11.A.7

No

Loading...

Loading...