kajaaniMCA

i

– Installation, Operating & Service - A5.2 - W4610201 V2.5 EN

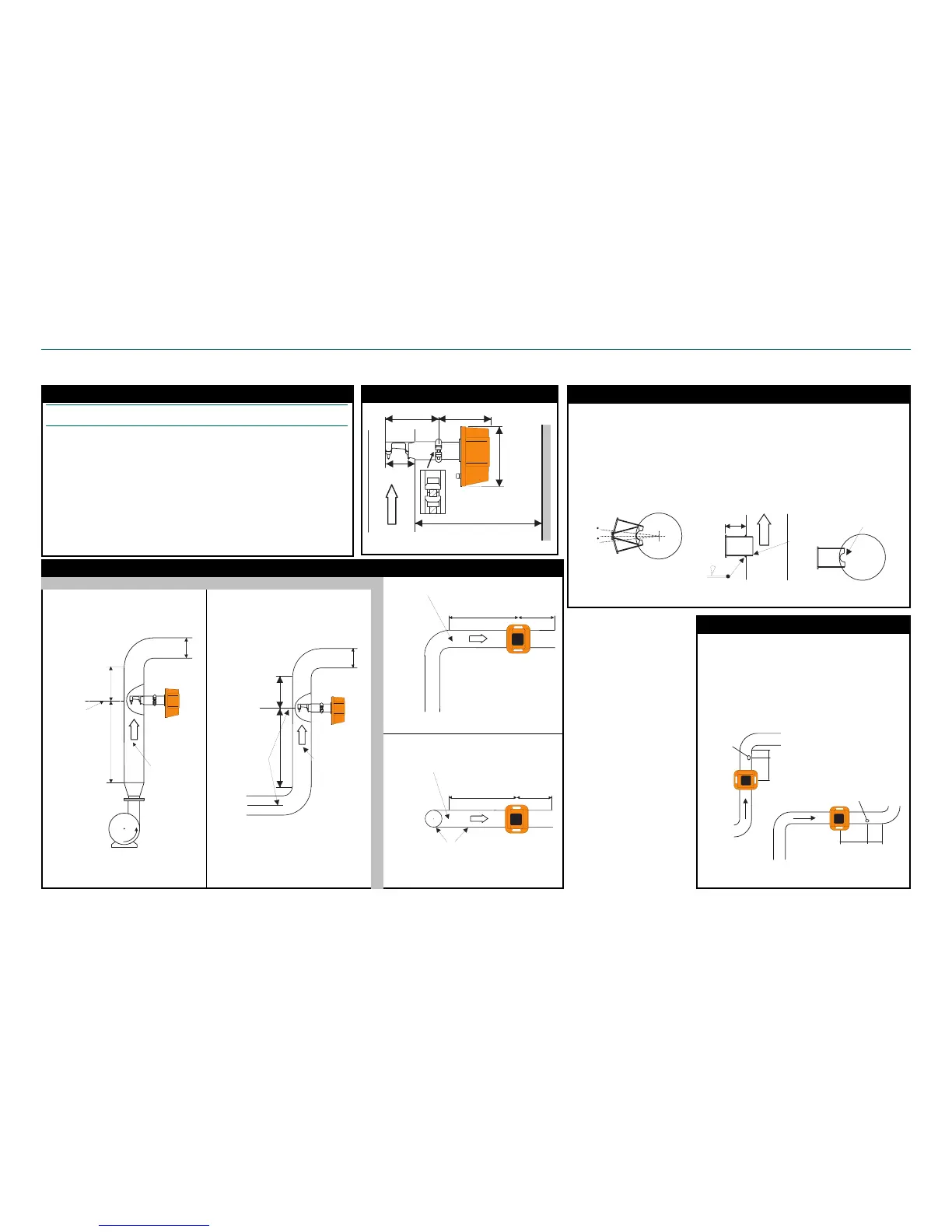

D

Min. 2 x D

(1 x D if Cs >8%)

Meas. line at a 90°

angle with regard to

pump axis

Min. 4 x D

(2 x D if Cs >8%)

Required straight

pipe section.

No valves or

other devices

protruding into

the pipeline.

FLOW

Installing an MCAi-F / MCAi-FS consistency sensor

NOTE: Before any installation work, make sure that the process pipeline is not pressurized

and that the installation will be safe!

1. Pay attention to the following requirements for the installation point:

- process temperature max. 100 °C (+212 °F)

- pH 2.5 – 11.5

- pressure 1.5–25 bar (22–363 psi)

- do not install the sensor to the suction side of a pump

- conductivity in accordance with the sensor specifications (see App. 1)

2. Make sure that the FLOW arrow on the sensor housing is aligned with the process

flow direction.

3. Make sure that the installation point and sensor position are in accordance with the

instructions.

4. Protect the sensor and Display Unit from direct heat radiation (sun).

5. Make sure that the clamping collar of the process coupling is properly tightened.

6. The sensors are ceramic – be careful not to damage them!

Installing (welding) the process coupling to a horizontal pipeline:

• Install to a horizontal pipe as shown below – the coupling must be within ±5º of the horizontal

plane.

• Notches on the coupling aligned with the pipeline, the smaller notch against the flow (label

on the coupling indicates the correct flow direction)!

Installing (welding) the process coupling to a vertical pipeline:

• Install to a vertical pipe as shown below – the coupling must be within ±5º of the horizontal

plane.

• Notches on the coupling aligned with the pipeline, the smaller notch against the flow (label

on the coupling indicates the correct flow direction)!

Installing to

horizontal pipeline

(view from the side)

VIRATUS

111 m m

(4 3/8")

a5

Installing to vertical pipeline

(view from the side)

Notches on coupling

aligned with pipeline

(view from

above)

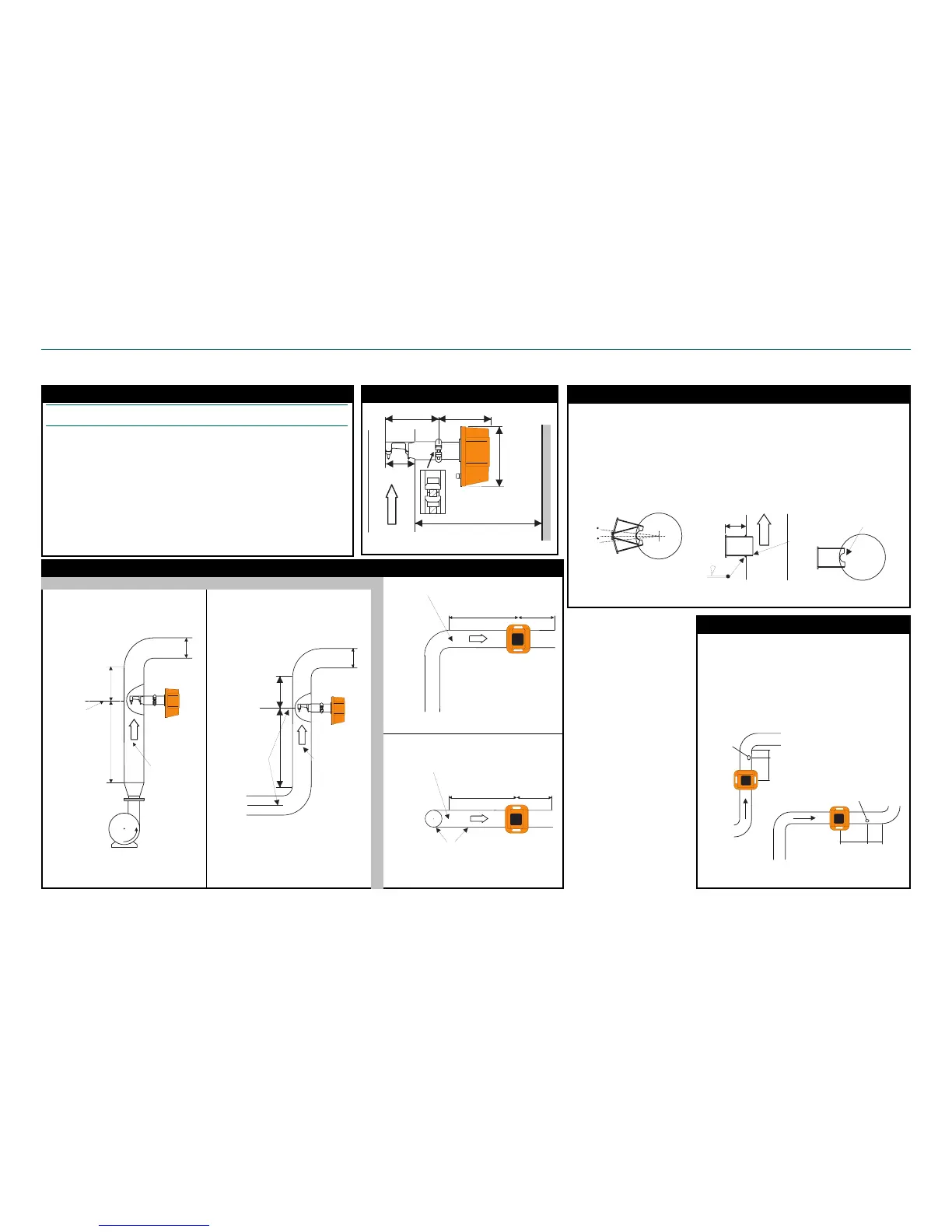

1. NOVE is usually installed after the MCA sensor. Make

sure that the distance between NOVE and MCA is ³ 2 x

D and ³1 x D of straight pipeline after the NOVE.

2. Install the NOVE at a 45° angle with respect to the MCA

measuring line.

3. If the NOVE cannot be installed after the MCA, install

it to the pipeline before MCA and make sure that there is

³4 x D of straight pipeline before the NOVE and ³1 x D

after it.

MCAi installation points

Check List for MCAi installation

MCAi-F &FS process coupling

D

FLOW

Meas. line

aligned with the

pipeline preceding

the bend.

Min. 4 x D

(2 x D if

Cs >8%)

Min. 2 x D

(1 x D if

Cs >8%)

Required straight

pipe section.

No valves or

other devices

protruding into

the pipeline.

Installation dimensions of the sensor

MCA

i

Required straight

pipe section.

No valves or

other devices

protruding into

the pipeline.

Min. 2xD

(1xD if

Cs>8%)

Min. 4xD

(1xD if Cs>8%)

FLOW

Vertical pipe

Horizontal pipe

MCA

i

Horizontal pipe

Required straight

pipe section.

No valves or

other devices

protruding into

the pipeline.

Min. 2xD

(1xD if

Cs>8%)

Min. 4xD

(1xD if Cs>8%)

FLOW

290 m m

(11 13/32")

272 m m

(10 23/32")

270 m m

(10 5/8")

m in. 600 m m (24")

161 m m

(6 11/32")

MCA

i

Nove

1xD

2xD

Vertical

pipeline

Installing a NOVE sampler

Loading...

Loading...