18 7 ND92F 70 en

The valve can now be unlocked.

5.6.5 LS status

LS shows the status of limit switches:

--- No LS active

CLO LS "Closed" active

OPE LS "Open" active

LSE LS Error, both switches activated

at the same time

5.7 Special displays

5.7.1 User interface locked

In order to prevent unauthorised access, the Local User

Interface may be locked. In this mode measurements

may be viewed but configurations and calibrations are

prohibited. You may lock and unlock the device only via

dip switch, see Fig.21. When the Local User Interface is

locked the lock symbol will be activated on the display.

5.7.2 Online-alarm active

If an online alarm has been detected the solid & symbol

is activated. This symbol will disappear after the recov-

ery from online alarm. You may view the reason for the

alarm by viewing the latest event while pushing the =

and - keys simultaneously or by using FieldCare soft-

ware where all events may be viewed.

5.7.3 Viewing of latest event

You may view the latest event by pressing the = and -

keys simultaneously in the measurement monitoring

view. The message is scrolled on the top row of the dis-

play twice. You may stop the scrolling by pressing the ?

key. By pressing the = key, the message will disappear.

For the list of events see Chapter 7.

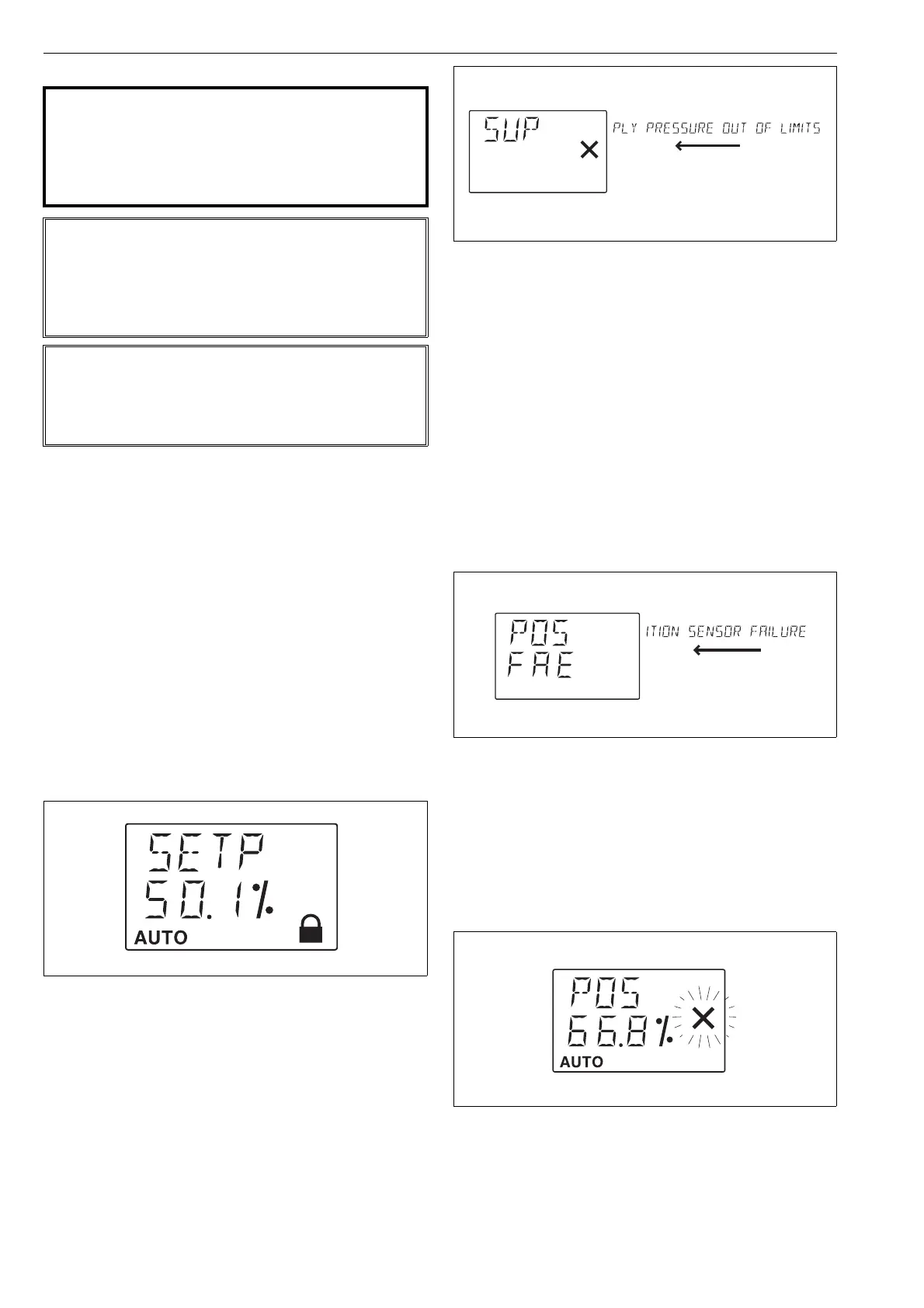

5.7.4 Fail-safe active

When the ND9200F detects serious device failure (set-

point, valve position and control signals) it enters fail-

safe mode, which drives the control valve into the posi-

tion defined in the parameter controller fail action (PFA).

Fail-safe mode is indicated by the display as seen in

Fig. 19. The error message is displayed until the cause

of error is eliminated and the ND9200F unit is restarted,

i.e. the power loop is momentarily disconnected.

5.7.5 Reduced Performance

When the ND9200F detects spool valve measurement

failure, it enters reduced performance mode. This is

indicated by the blinking & in the display, see Fig. 20.

In reduced performance mode valve control can not be

optimized. To correct the problem replace the spool

valve assembly and perform auto calibration.

WARNING:

Supply pressure can be connected to the valve

controller only after 1-point calibration is success-

fully completed. If supply pressure is connected to

the valve controller before successful 1-point cali-

bration, the valve may move and cause danger.

NOTE:

If an incorrect valve operation angle is given to the

valve controller during 1-point calibration, valve oper-

ation will be incorrect. In this case, you must perform

1-point calibration again with correct valve operation

angle value.

NOTE:

If the valve position is not stable (due to heavy vibra-

tion etc) during 1-point calibration, the calibration will

not end successfully. Check that the valve position is

fully stable during this operation.

Fig. 17 LUI locked

Fig. 18 Online alarm message

Fig. 19 Failsafe display

Fig. 20 Reduced performance display

scrolling text

scrolling text

Loading...

Loading...