7 ND92F 70 en 19

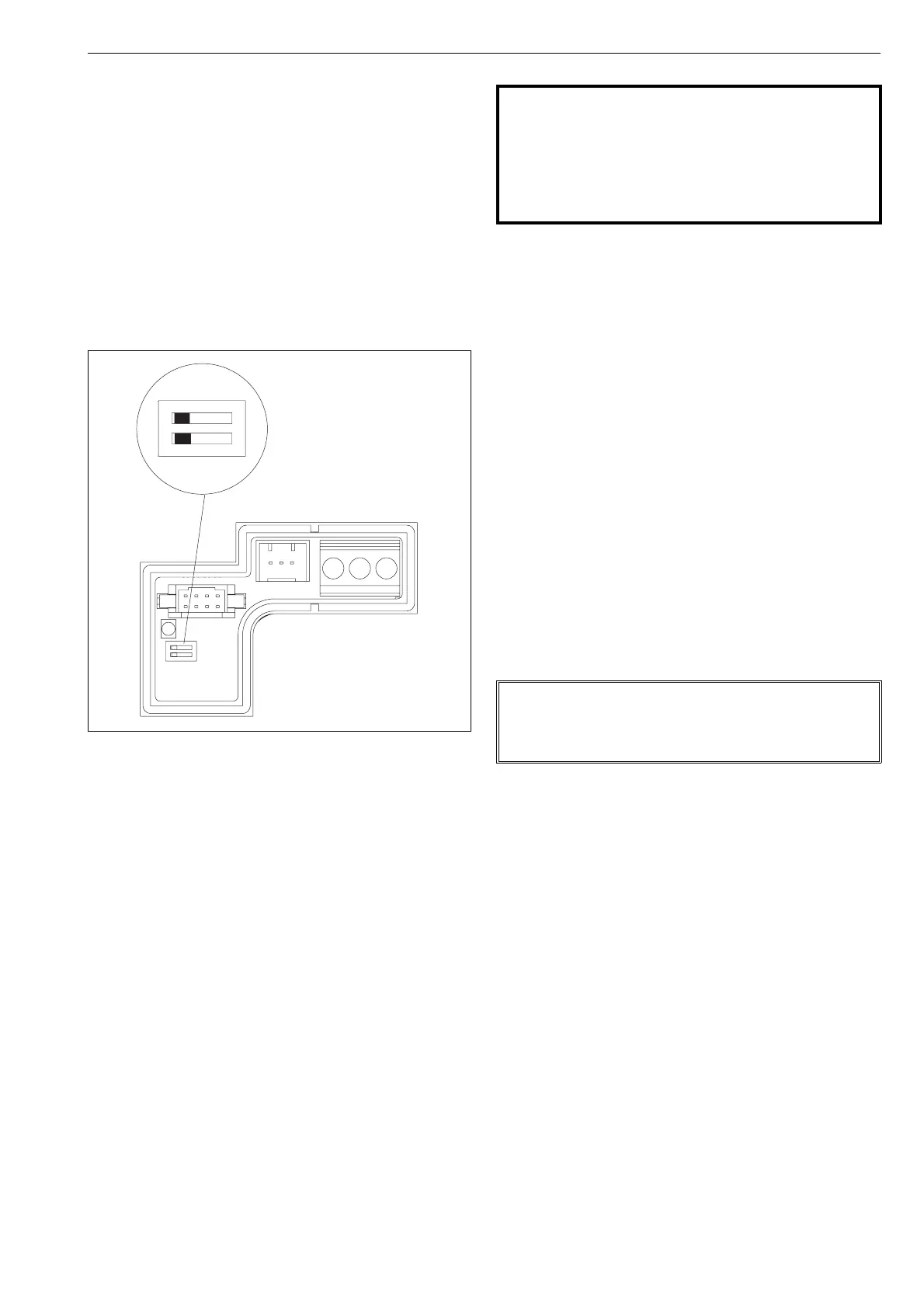

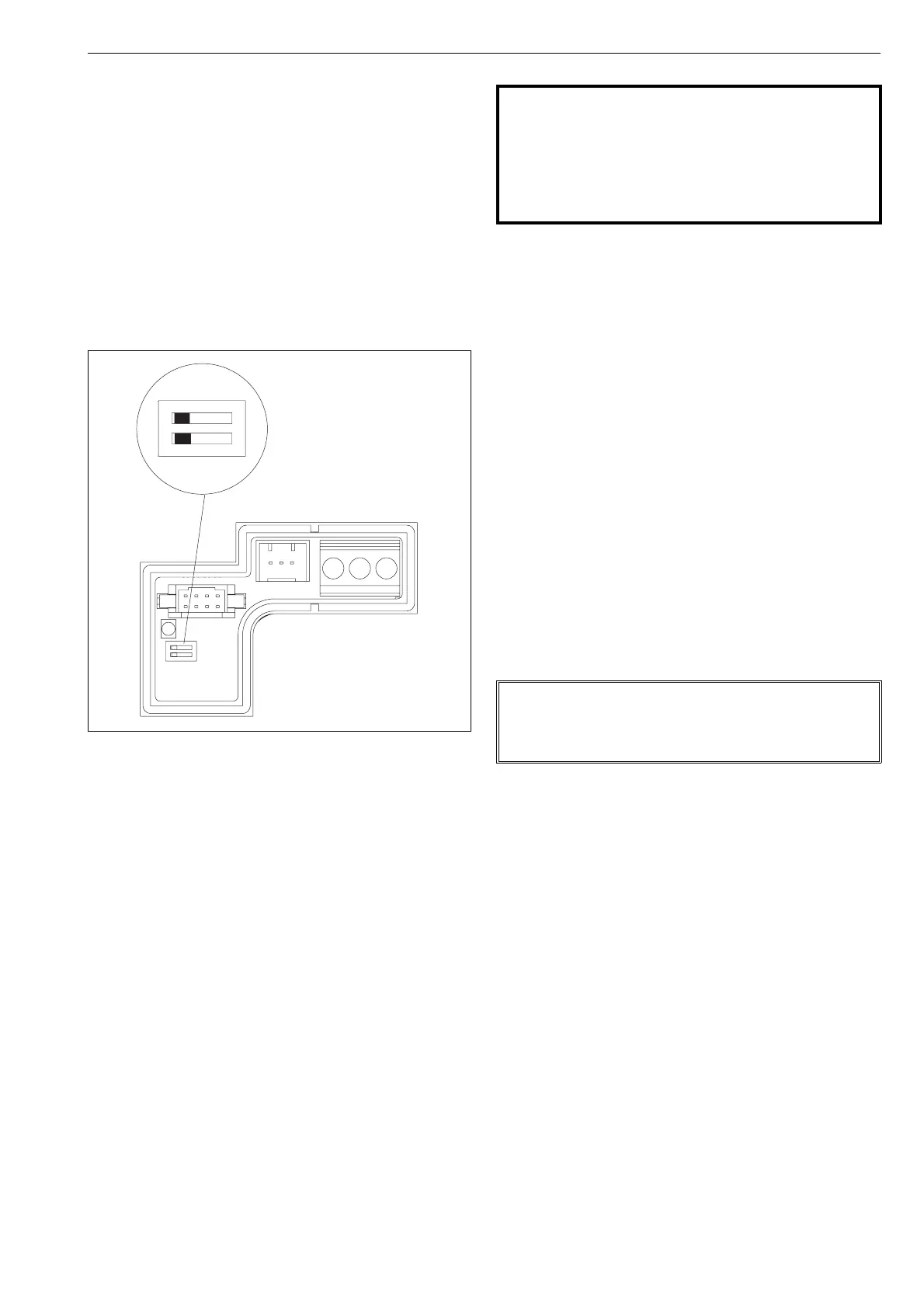

5.8 Write protection

The ND9200F is delivered from the factory with HW

write protection OFF as the default setting. Reading

and changing parameters is thus allowed. Write protec-

tion can be enabled with the switch (DIP1) located on

the circuit board (Fig. 21).

Write protection protects all write access to all writeable

parameters of the device. Changing the parameters

from the LUI or Fieldbus configurator is thus not

allowed.

The simulation switch is OFF as the default setting. A0

block simulation is thus disabled. The simulation can be

enabled with the switch (DIP2) located on the circuit

board (Fig 21).

6 MAINTENANCE

The maintenance requirements of the ND9200F valve

controller depend on the service conditions, for

instance, the quality of instrument air. Under normal

service conditions there is no requirement for regular

maintenance.

When maintaining the ND9200F ensure that the supply

air is shut off and pressure is released. In the following

text the numbers in brackets ( ) correspond to the part

numbers in the exploded view as shown in Chapter 11,

unless otherwise stated.

The ND9200F valve controller includes the following

interchangeable modules: prestage unit (120), spool

valve (193), communication circuit board with optional

position transmitter (215).

The spool valve is located on the bottom side of the

device while the other modules are located below the

covers (100) and (39). In the event of failure the whole

module must be changed. The module retrofit must be

assembled in a clean, dry environment. In reassembly

apply a thread-locking compound (for instance, Loctite

243) and tighten the screws firmly.

6.1 Prestage

6.1.1 Removal

❑ Loosen the M8 stop screw (110) in the position

indicator (109) and turn the position indicator

from the shaft (11). Remove the inner cover (39)

attached with M3 screws (42, 3 pcs).

❑ Unplug the prestage wire connector from the

spool sensor board (180). Unscrew the M4

screws (139, 2 pcs.) and lift up the prestage

module. Remove the O-ring (140).

6.1.2 Installation

❑ Place a new O-ring (140) into the groove in the

housing and press the prestage into place. Make

sure the nozzle is guided into the O-ring properly.

The screws guide the prestage body into the cor-

rect position. Tighten the screws (139) evenly.

❑ Push the prestage 2-pole wire connector into the

socket on the spool sensor board. The wire con-

nector can only be fitted in the correct position.

Replace the inner cover (39) and tighten the M3

screws.

Fig. 21 Write protection

12

ON

Ex d WARNING:

Service of the cylindrical flameproof joints is not

allowed.

This includes the diaphragm cover (part 171), flame

arrester plunger (part 200), their mating surfaces in

the housing (part 2) and the shaft assembly fixed in

the housing.

NOTE:

The prestage must be handled carefully. In particular

the moving parts of the prestage should not be

touched when the inner cover (39) is not in place.

Loading...

Loading...