4 7 ND92F 70 en

2 ND9200F INTELLIGENT VALVE

CONTROLLER WITH FOUNDATION

FIELDBUS COMMUNICATION

2.1 General

This manual incorporates Installation, Maintenance and

Operation Instructions for the Metso ND9200F intelligent

valve controller. The ND9200F may be used with either

cylinder or diaphragm type pneumatic actuators for

rotary or linear valves.

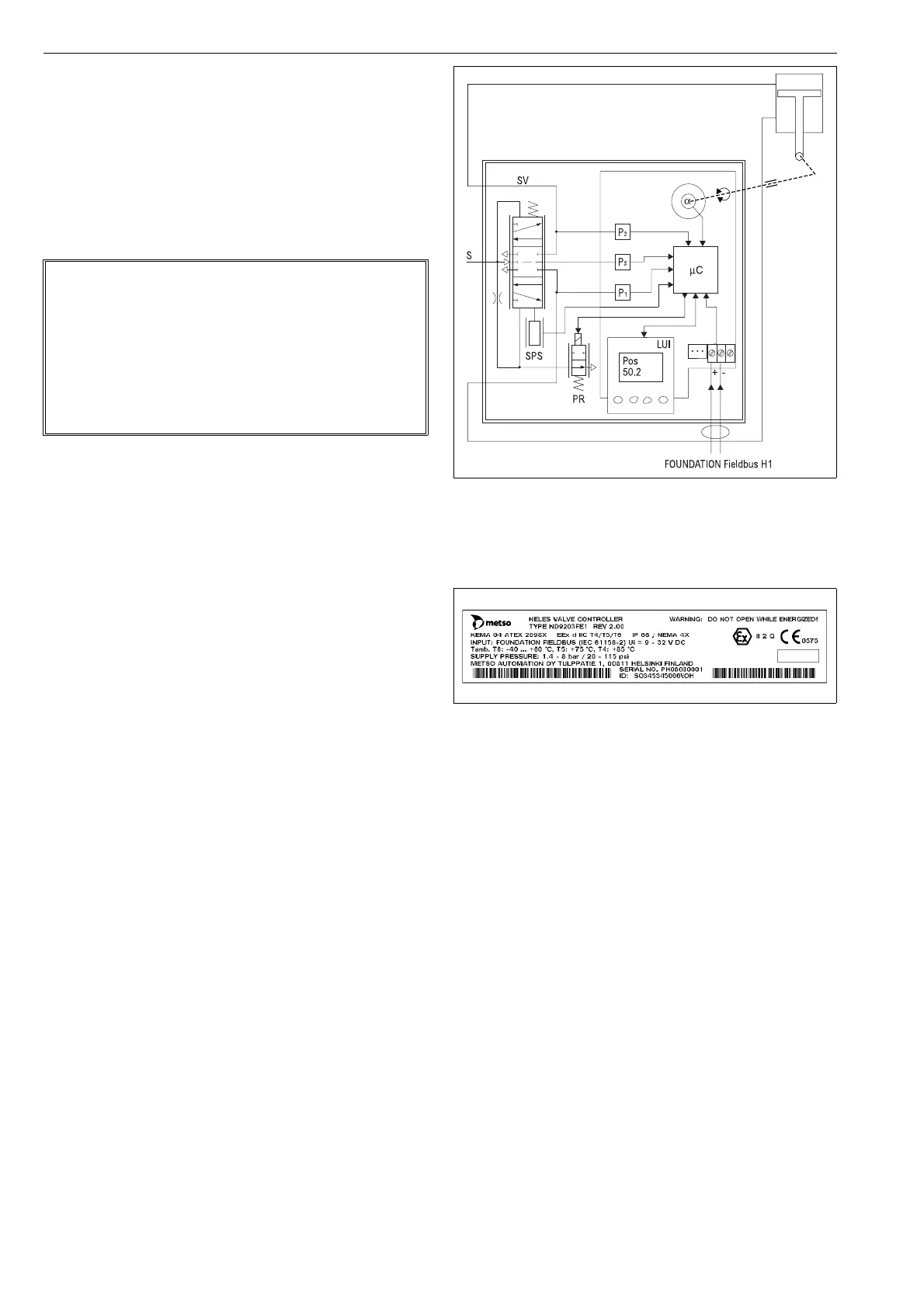

2.2 Technical description

The ND9200F is a fieldbus powered microcontroller-

based intelligent valve controller. The ND9200F configu-

ration can be done either using local push buttons or

FOUNDATION Fieldbus configurator.

The powerful 32-bit microcontroller controls the valve

position. The measurements include:

❑ Input signal

❑ Valve position with contactless sensor

❑ Actuator pressures, 2 independent measurements

❑ Supply pressure

❑ Spool valve position

❑ Device temperature

Advanced self-diagnostics guarantees that all measure-

ments operate correctly. Failure of one measurement

does not cause the valve to fail if the input signal and

position measurements are operating correctly. After

connections of electric signal and pneumatic supply the

micro controller (µC) reads the input signal, position sen-

sor (α), pressure sensors (Ps, P1, P2) and spool position

sensor (SPS). A difference between input signal and

position sensor (α) measurement is detected by the con-

trol algorithm inside the µC. The µC calculates a new

value for prestage (PR) coil current based on the infor-

mation from the input signal and from the sensors.

Changed current to the PR changes the pilot pressure to

the spool valve. Reduced pilot pressure moves the spool

and the actuator pressures change accordingly. The

spool opens the flow to the driving side of the double

diaphragm actuator and opens the flow out from the

other side of the actuator. The increasing pressure will

move the diaphragm piston. The actuator and feedback

shaft rotate clockwise. The position sensor (α) measures

the rotation for the µC. The µC using control algorithm

modulates the PR-current from the steady state value

until a new position of the actuator according to the input

signal is reached.

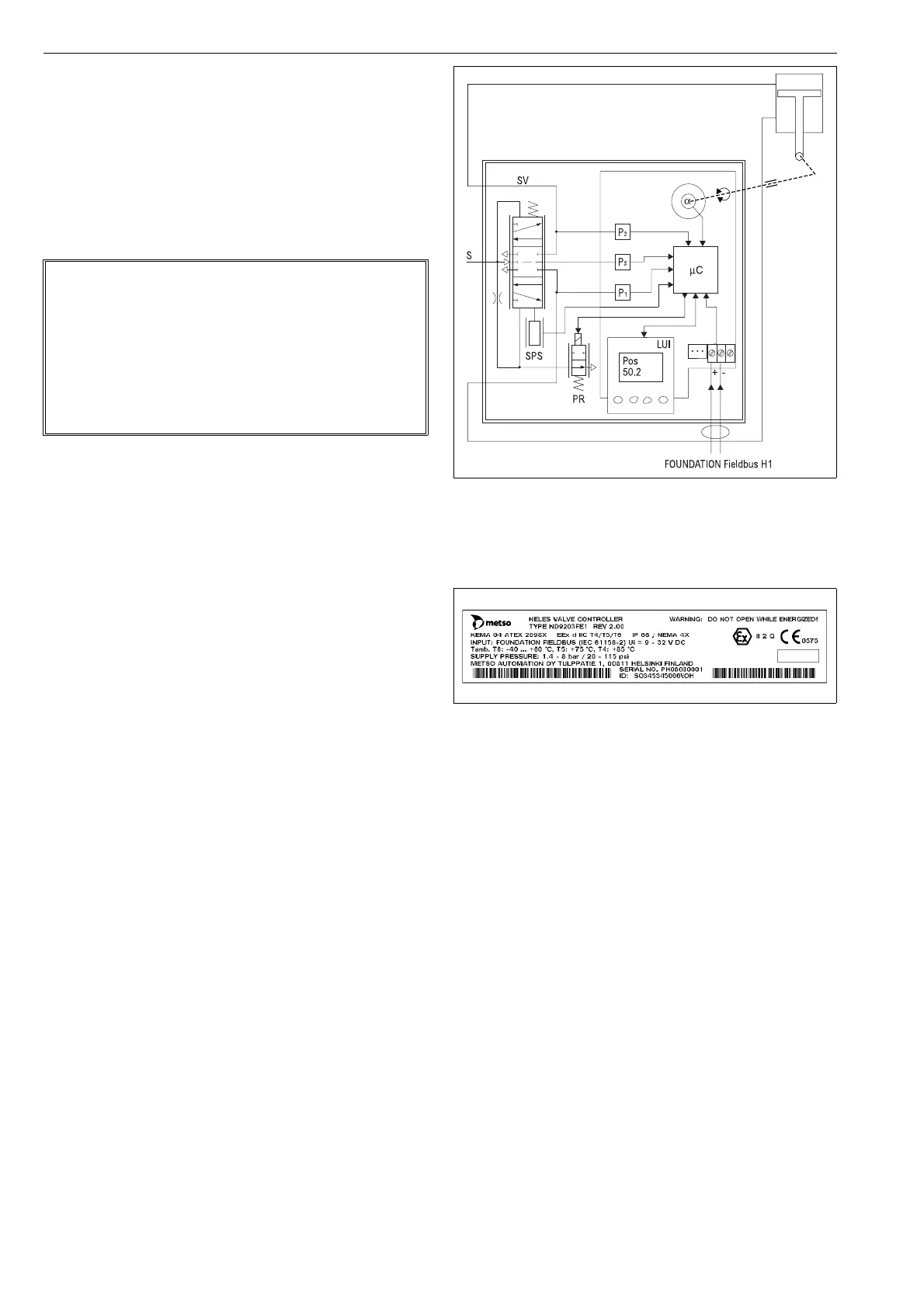

2.3 Markings

The valve controller is equipped with an identification

plate sticker (Fig. 2).

Identification plate markings from top to bottom include:

❑ Type designation of the valve controller

❑ Revision number

❑ Enclosure class

❑ Input signal (voltage range)

❑ Input resistance

❑ Maximum supply voltage

❑ Operational temperature

❑ Supply pressure range

❑ Contact details of the manufacturer

❑ CE mark

❑ Manufacturing serial number TTYYWWNNNN*)

*) Manufacturing serial number explained:

TT= device and factory sign

YY= year of manufacturing

WW = week of manufacturing

NNNN = consecutive number

Example: PH08011234 = controller, year 2008, week 1,

consecutive number 1234.

NOTE:

The selection and use of the valve controller in a specific

application requires close consideration of detailed

aspects. Due to the nature of the product, this manual

cannot cover all the likely situations that may occur when

installing, using or servicing the valve controller.

If you are uncertain about the use of the controller or its

suitability for your intended use, please contact Metso’s

Automation business for more information.

Fig. 1 The principle of operation

Fig. 2 Identification plate

Loading...

Loading...