1. Installation

1 - 7

1-1-6 Cable stress

<1> Sufficiently consider the cable clamping method so that bending stress and the stress from the

cable's own weight is not applied on the cable connection part.

<2> In applications where the servomotor moves, make sure that excessive stress is not applied on the

cable.

If the detector cable and servomotor wiring are stored in a cable bear and the servomotor moves,

make sure that the cable bending part is within the range of the optional detector cable.

Fix the detector cable and power cable enclosed with the servomotor.

<3> Make sure that the cable sheathes will not be cut by sharp cutting chips, worn by contacting the

machine corners, or stepped on by workers or vehicles.

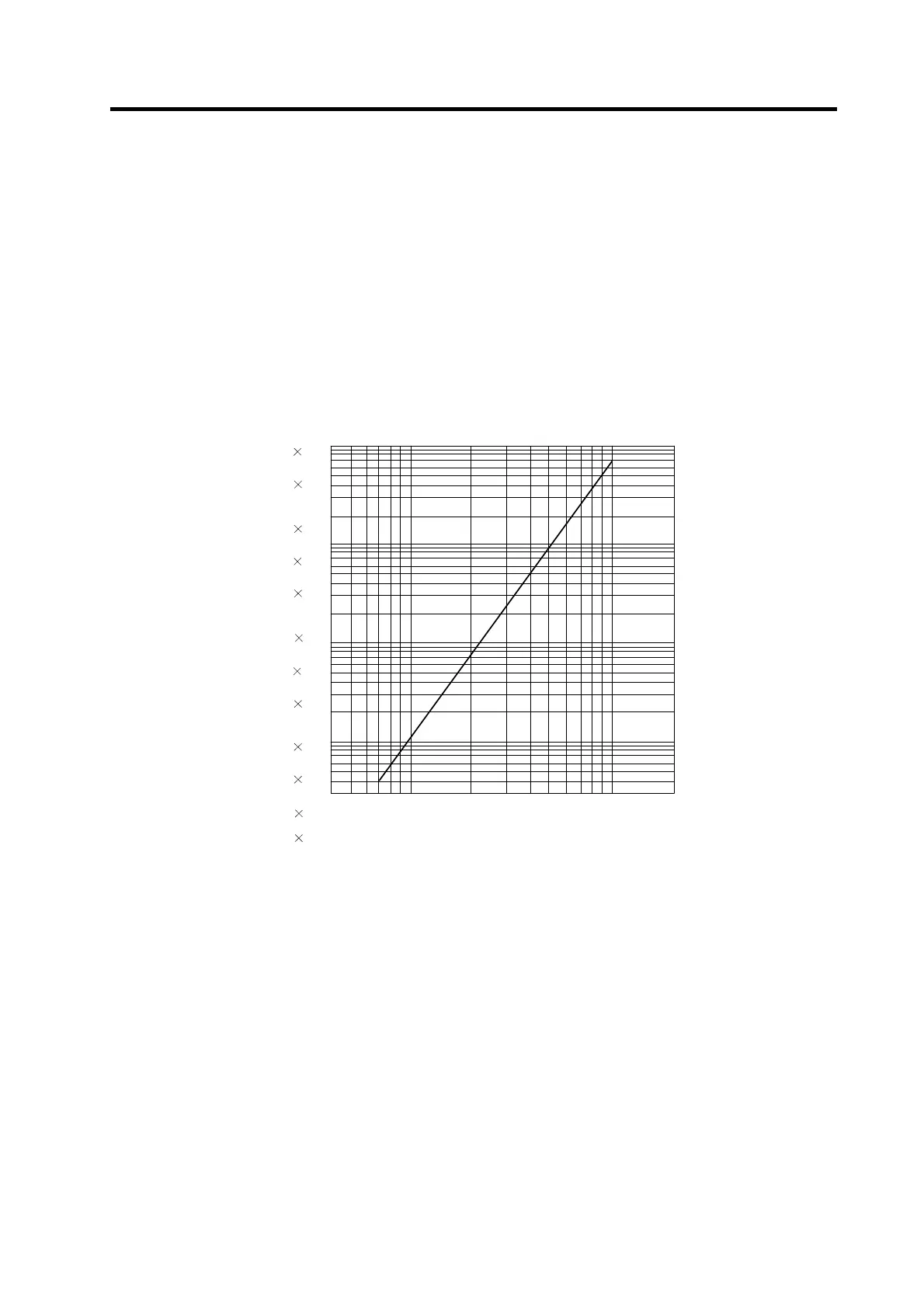

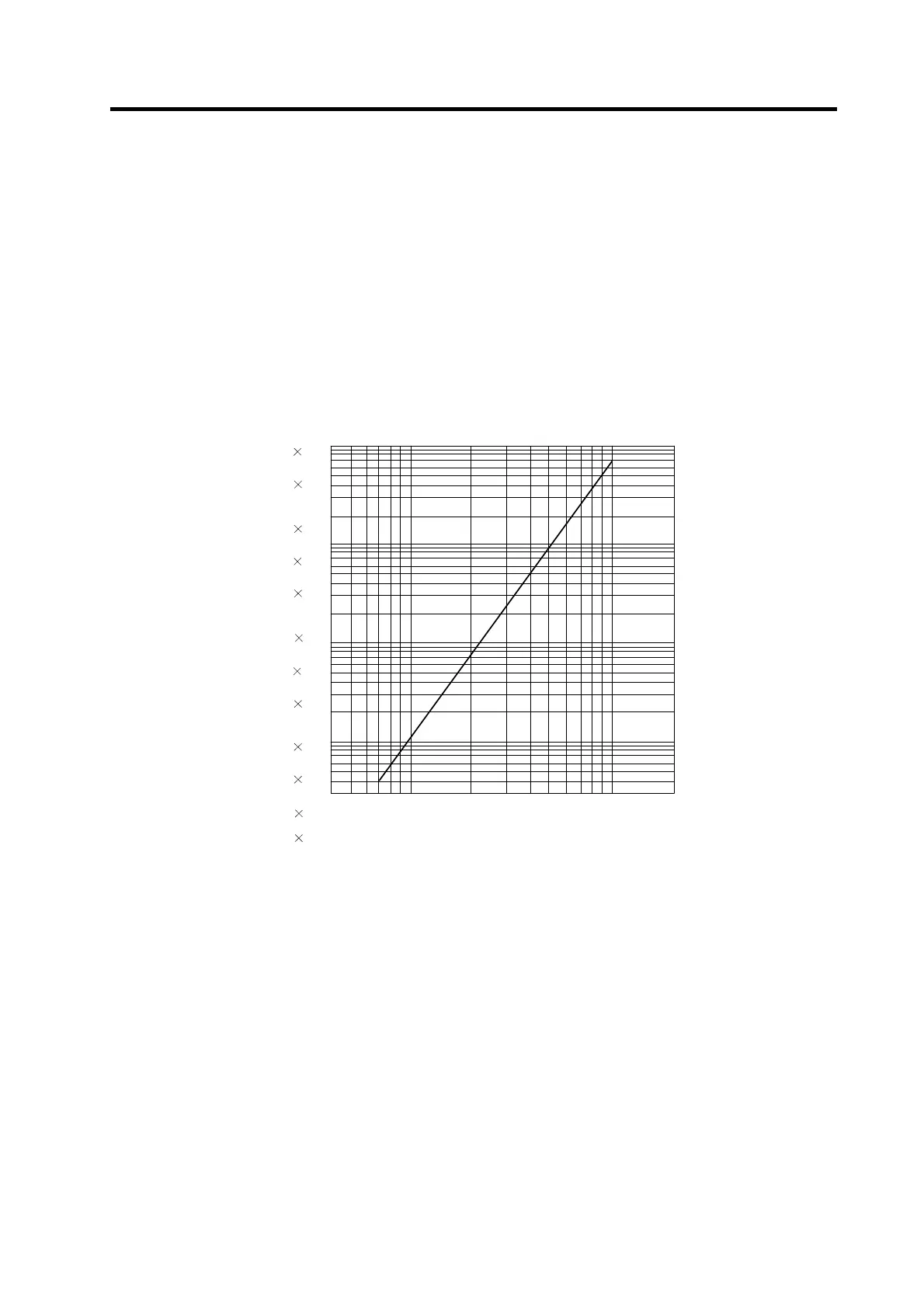

The bending life of the detector cable is as shown below. Regard this with a slight allowance. If the

servomotor/spindle motor is installed on a machine that moves, make the bending radius as large

as possible.

4 7 10 20 40 70 100 200

110

8

510

7

210

7

110

7

510

6

210

6

110

6

510

5

210

5

110

5

510

4

310

4

N

o

.

o

f

b

e

n

d

s

(

t

i

m

e

s

)

Bending radius (mm)

Detector cable bending life

(Mitsubishi optional detector cable and wire material: A14B2343)

Note: The values in this graph are calculated values and are not guaranteed.

Loading...

Loading...