Appendix 3. EMC Installation Guidelines

A3 - 7

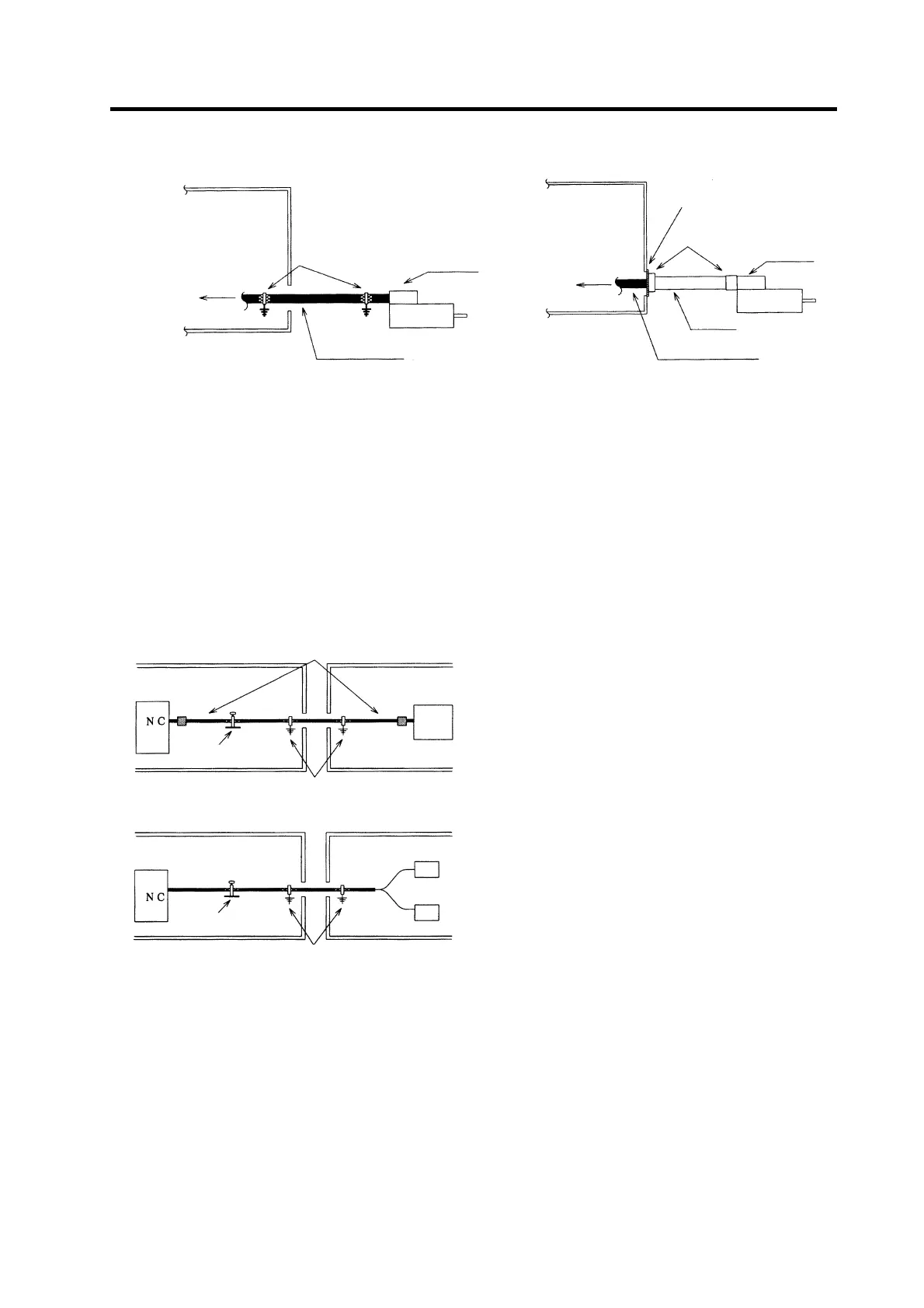

Appendix 3-5-5 Spindle motor power cable

Control panel

To drive unit

Earth with

P or U clip

Terminal

box

Shield cable

Spindle moto

Control panel

To drive unit

Conduit

connecto

Conduit

Cabtyre cable

Terminal

box

Earth with paint mask

Using shield cable Using conduit

(1) Use four wires (3-phase + earthing) for the power cable that are completely shielded and free from

breaks.

(2) Earth the shield in the same manner as the servomotor power cable.

(3) When not using a shield cable for the power cable, use a conventional cabtyre cable. Use a metal

conduit outside the cable.

(4) Earth the power cable on the control panel side at the contact surface of the conduit connector and

control panel side wall in the same manner as the servomotor power cable. (Mask the side wall of

the control panel with paint.)

(5) Earth at the conduit connector section in the same manner as the servomotor power cable.

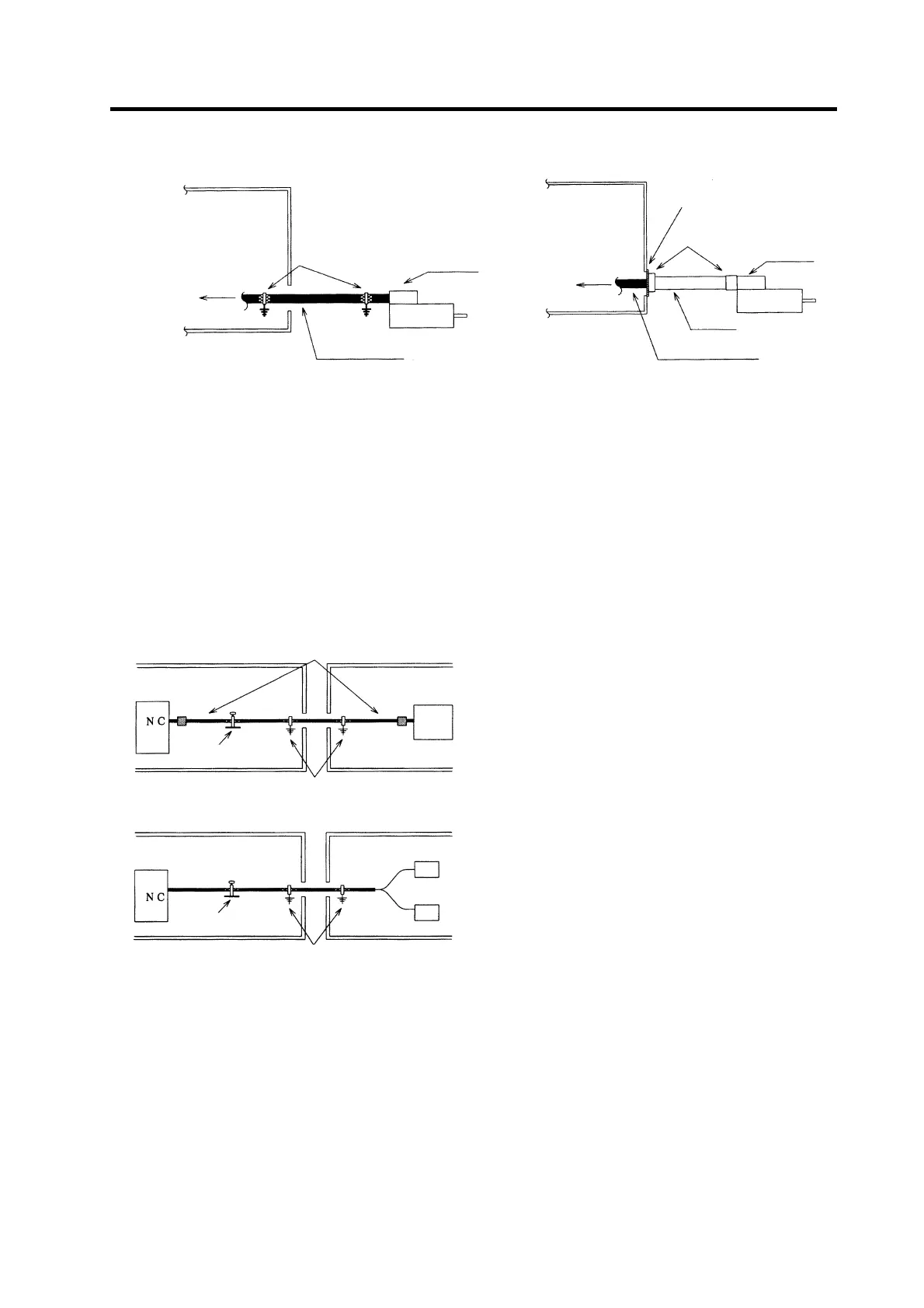

Appendix 3-5-6 Cable between control panel and operation board panel

Control

anel

Operation board panel

Clamp fitting

enclosed with NC

Board

SH11 cable (signal cable)

Ferrite core (Within 10cm from device)

Earth with P or U clip

Control

anel

Operation board panel

Clamp fitting

enclosed with NC

Board

PD05 cable (power supply cable)

Earth with P or U clip

(1) Use a shield cable for the cable between the

control panel and operation board.

(2) Earth the shield in the same manner as the

other cables.

(3) Insert a ferrite core in the SH11 cable at a

position within 10cm from the device.

(This provides a better effect.)

The PD05 cable is used with the MELDAS500

Series.

Refer to the EMC INSTALLATION GUIDELINES

for each NC for details.

Loading...

Loading...