5. Spindle Adjustment

5 - 16

5-3-2 Adjusting the acceleration/deceleration operation

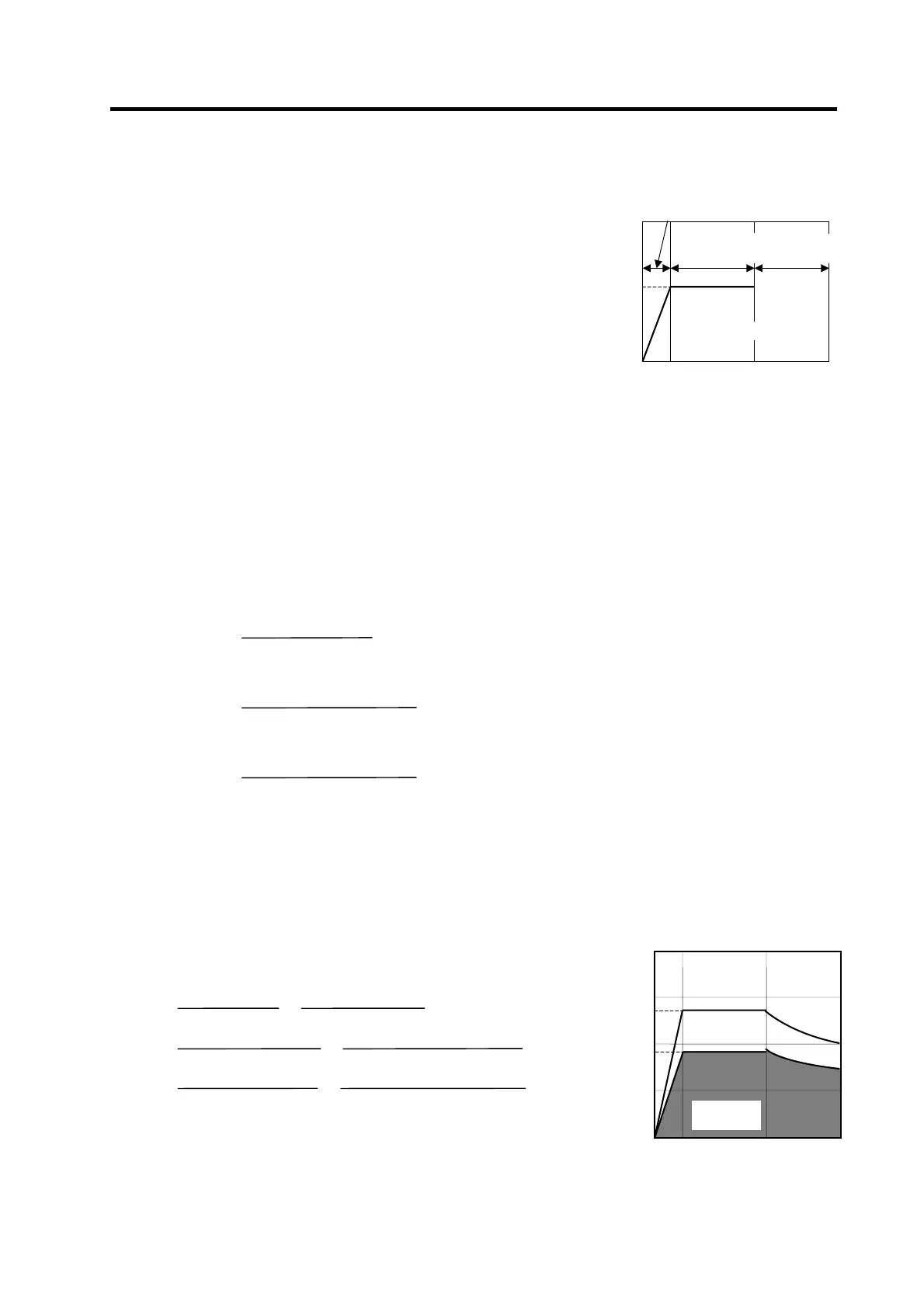

(1) Calculating the theoretical acceleration/deceleration time

The theoretical acceleration/deceleration time is calculated

for each output range based on the spindle motor output

characteristics as shown on the right. Note that the load

torque (mainly frictional torque) is assumed to be 0 in this

theoretical expression, so the time tends to be shorter than

the acceleration time with the actual machine.

1) Maximum motor output during

acceleration/deceleration: Po

During acceleration/deceleration, the motor can output at

120% of the short-time rating. Thus, the motor output Po

in the output range during acceleration/deceleration

follows the expression below.

Po = (Short-time rated output) × 1.2 [W]

2) Total load GD

2

: GD

2

GD

2

of the total load which is accelerated and decelerated follows the expression below.

GD

2

= (Motor GD

2

) + (motor shaft conversion load GD

2

) [kg•m

2

]

The acceleration/deceleration time for each output range is calculated as shown below, using

the values obtained in 1) and 2).

3) Acceleration/deceleration time for constant torque range: t1

t1 =

1.03

GD

× N1

375 × Po

[s]

4) Acceleration/deceleration time for constant output range: t2

t2 =

1.03

GD

× (N2

- N1

)

2 × 375 × Po

[s]

5) Acceleration/deceleration time in deceleration output range: t3

t3 =

1.03

GD

× (N3

- N2

)

3 × 375 × Po × N2

[s]

Based on the above expressions, the acceleration/deceleration time: t from 0 to N3 [r/min] is:

t = t1 + t2 + t3 [s]

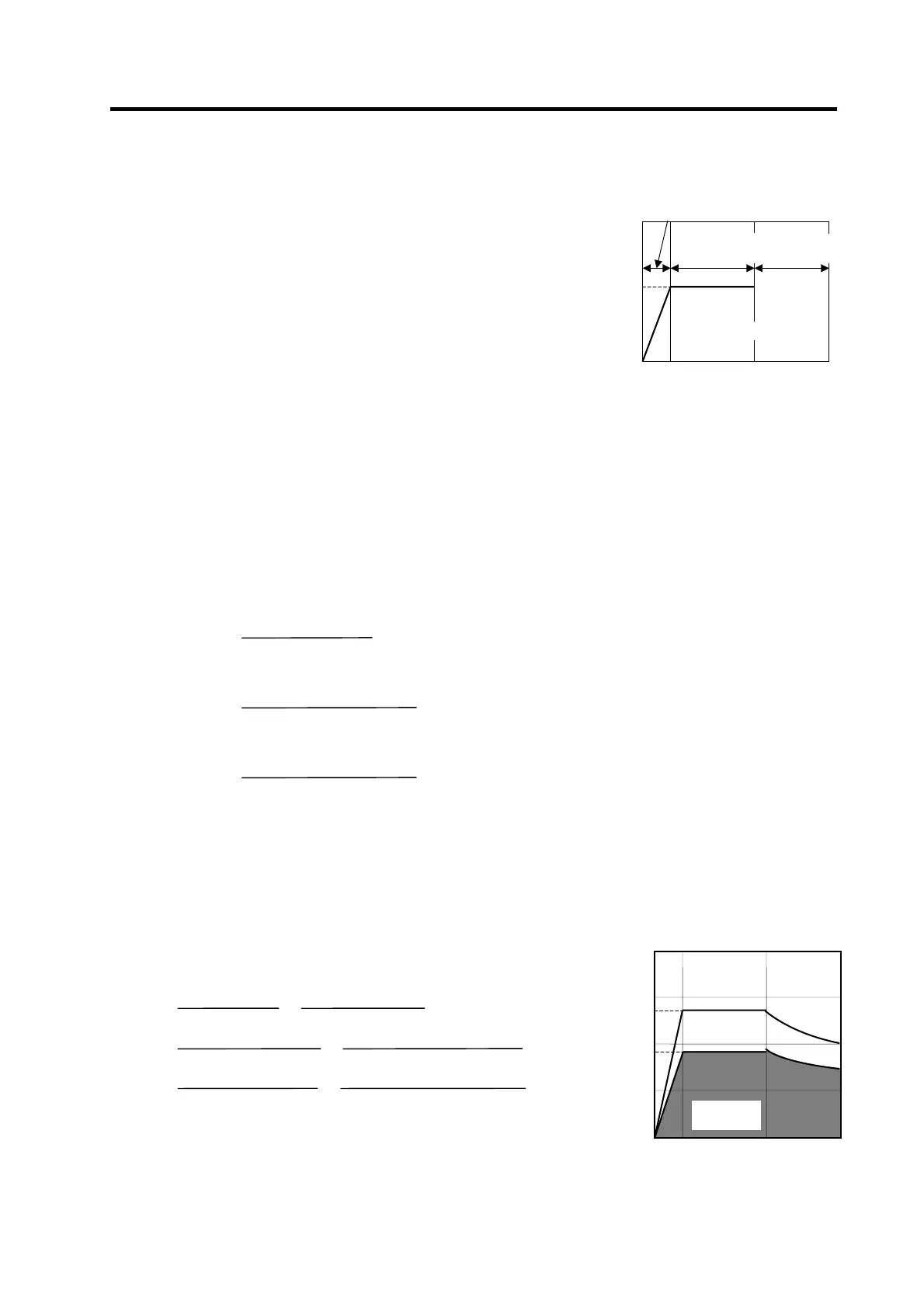

[Calculation example]

Calculate the acceleration/deceleration time from 0 to 10000[r/min] for an SJ-V5.5-01 motor having

the output characteristics shown on the right, when the motor shaft conversion load GD

2

is

0.2[kg

•m

2

].

Po = (Short-time rated output) × 1.2 = 5500 × 1.2 = 6600 [W]

GD

2

= (Motor GD

2

) + (load GD

2

) = 0.059 + 0.2 = 0.259 [kg•m

2

]

t1 =

1.03

×

GD

×

N1

375

×

Po

=

1.03

×

0.259

×

1500

375

×

6600

= 0.063[s]

t2 =

1.03

×

GD

×

(N2

- N1

)

2

×

375

×

Po

=

1.03

×

0.259

(6000

- 1500

)

2

×

375

×

6600

= 0.471[s]

t3 =

1.03

×

GD

×

(N3

- N2

)

3

×

375

×

Po

×

N2

=

1.03

×

0.259

(10000

- 6000

)

3

×

375

×

6600

×

6000

= 1.216[s]

Thus,

t = t1 + t2 + t3 = 0.063 + 0.471 + 1.216 = 1.75 [s]

0

N1

N2

0

Output [W]

N3

Po

Rotation speed [r/min]

Output characteristics for

acceleration/deceleration

Short-time rating

1.2

Constant

output range

Constant out

ut ran

e

Deceleration

range

0

1500

6000

0

2.0

6.0

8.0

4.0

Output [kW]

10000

15-minute

ratin

3.7

5.5

4.1

Continuous

rating

Rotation speed [r/min]

SJ-

5.5-01 out

ut characteristics

2.8

Loading...

Loading...