2. Wiring and Connection

2 - 46

2-11-3 Example of emergency stop circuit

(1) Outline of function

The power supply unit's external emergency stop can be validated by wiring to the CN23 connector,

and setting the parameters and rotary switch. If the emergency stop cannot be processed and the

external contractor cannot be shut off (due to a fault) by the CNC unit, the external contactor can be

shut off by the power supply unit instead of the CNC. At this time, the spindle motor will coast and

the servomotor will stop with the dynamic brakes.

EN60204-1 Category 1 can be basically complied with by installing the external emergency stop

switch and contactor.

CAUTION

1. The power supply unit external emergency stop function is a function that

assists the NC emergency stop.

2. The emergency stop signal input to the CNC side cannot be used as a

substitute for the external emergency stop function (CN23).

3. It will take 30 seconds for the external contactor to function after the

emergency stop is input to CN23. (This time is fixed.)

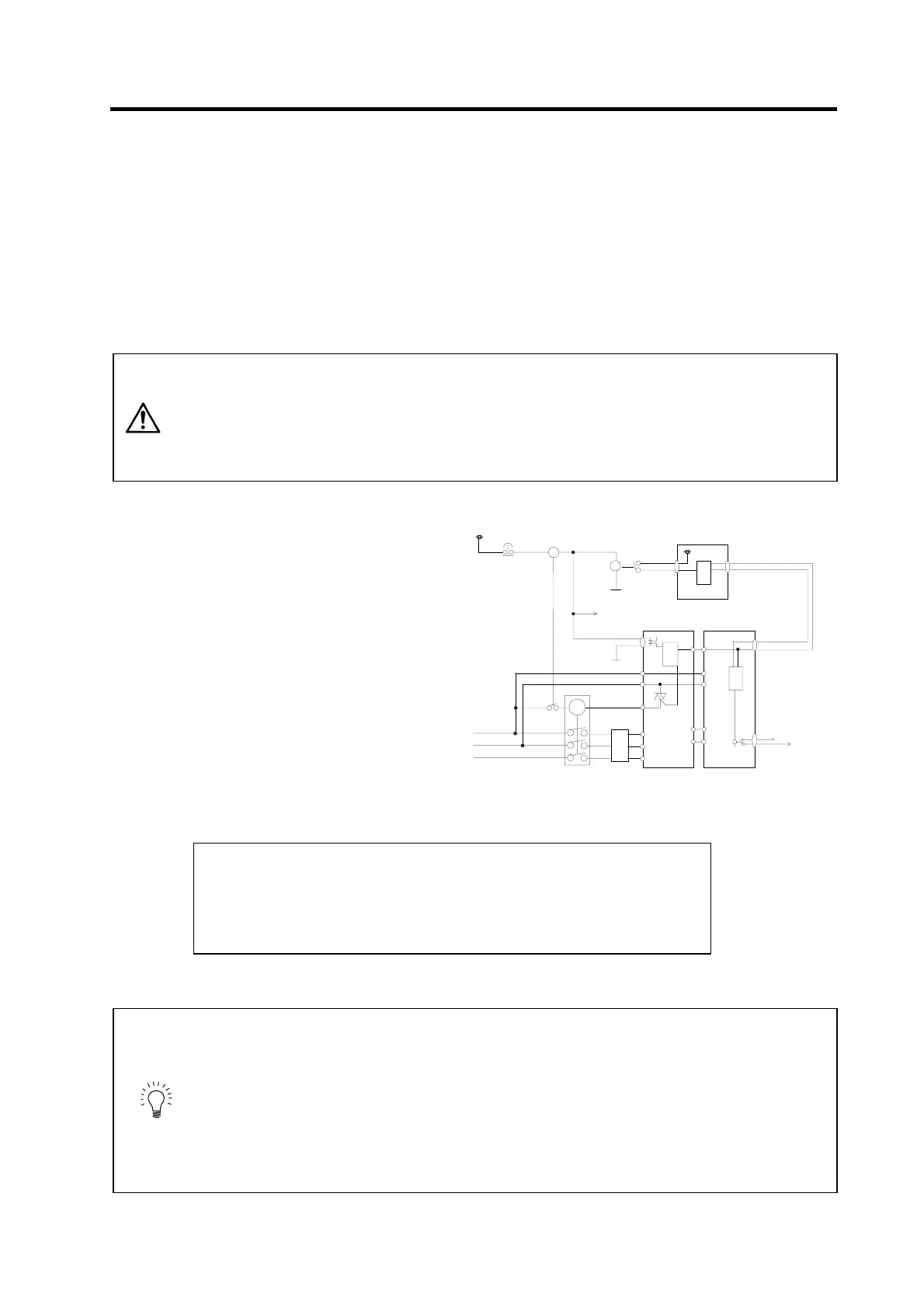

(2) Example of emergency stop circuit

The emergency stop is a signal used to

stop the machine in an emergency. This

is connected to the CNC unit. Wire to the

power supply unit when necessary.

The servo/spindle unit will be decelerated

and controlled by the software according

to the deceleration stop command issued

from the CNC unit.

The diagram on the right shows an

example of the emergency stop circuit

(EN60204-1 Category 0 stop) in which an

off delay timer (TM1) is installed as a

power shutoff method independent from

the NC emergency stop input. The

required safety category may be high

depending on the machine and the Safety Standards may not be met. Thus, always pay special

attention when selecting the parts and designing the circuit.

Setting the off delay timer (TM1) time

Set the TM1 operation time so that it functions after it has been confirmed that all axes have

stopped.

If the set time is too short, the spindle motor will coast to a stop.

tm

≥ All axes stop time

Provide a mechanism that shuts off the power even if the CNC system fails.

POINT

Stop Categories in EN60204-1

• Category 0: The power is instantly shut off using machine parts.

• Category 1: The drive section is stopped with the control (hardware/software

or communication network), and then the power is instantly shut

off using machine parts.

(Caution) Refer to the Standards for details.

Refer to Section 9.2.5.4.2 in EN60204-1: Safety of Machinery

Electrical Equipment of Machines – Part 1.

GND

R

R

GND

External

Emergency

Switch

TM1

RA1

MBR*

EMG

CUP

&

ASIC

SV1/2

CN23

Hardware Emergency

Software Emergency

NC Unit

Power Supply

Unit

Servo/Spindle

Drive Unit

CN1A/B

CUP

&

ASIC

CUP

&

ASIC

MC-OFF*

MC1

L1

L2

L3

L21

L11

CN4

CN4

CN20

MBR*

Motor

Brake

AC Reactor

External

Contactor

MC

L21

L11

P

N

Loading...

Loading...