10 - 4

10.1 General Safety Requirements

10

LOADING AND INSTALLATION

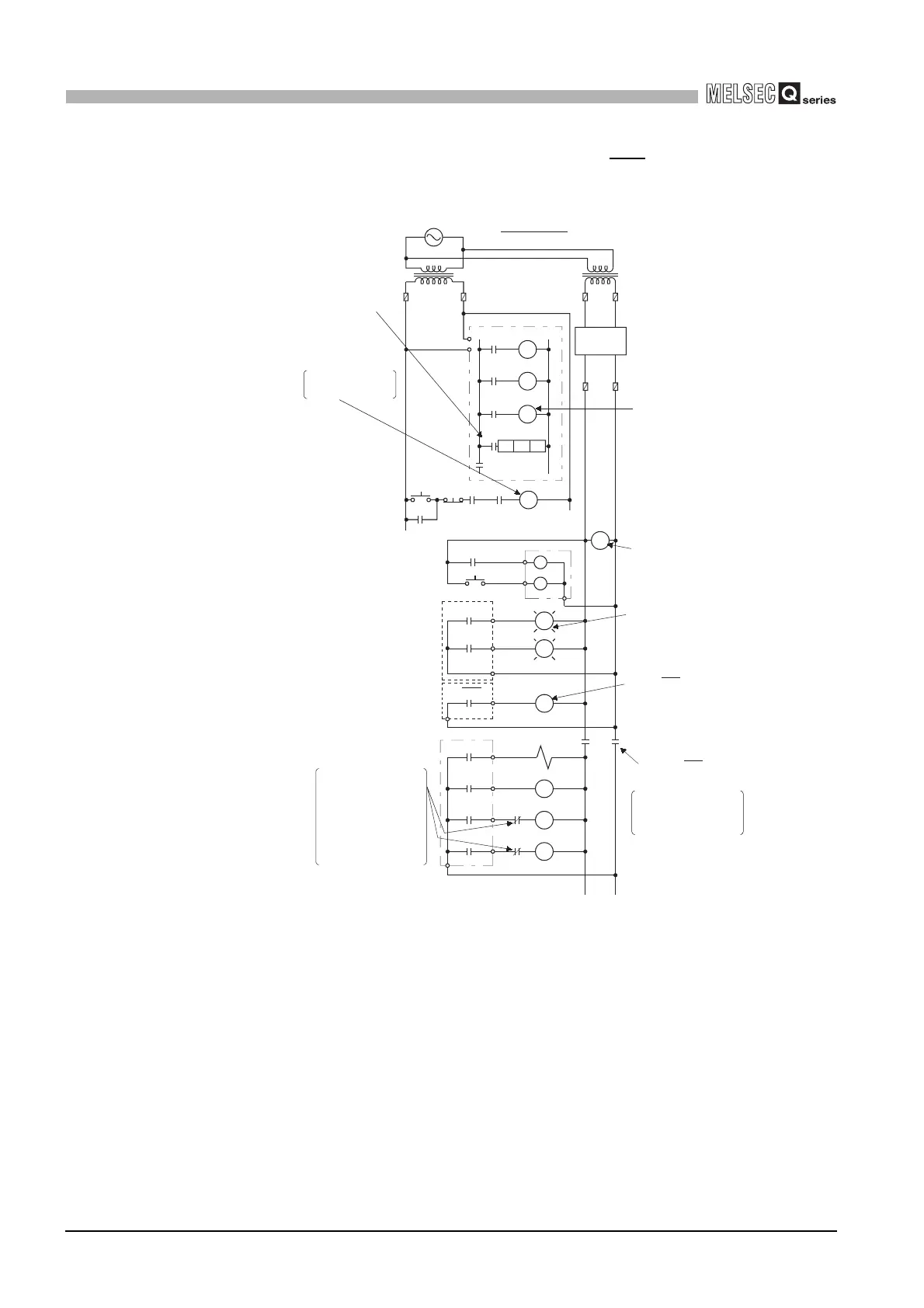

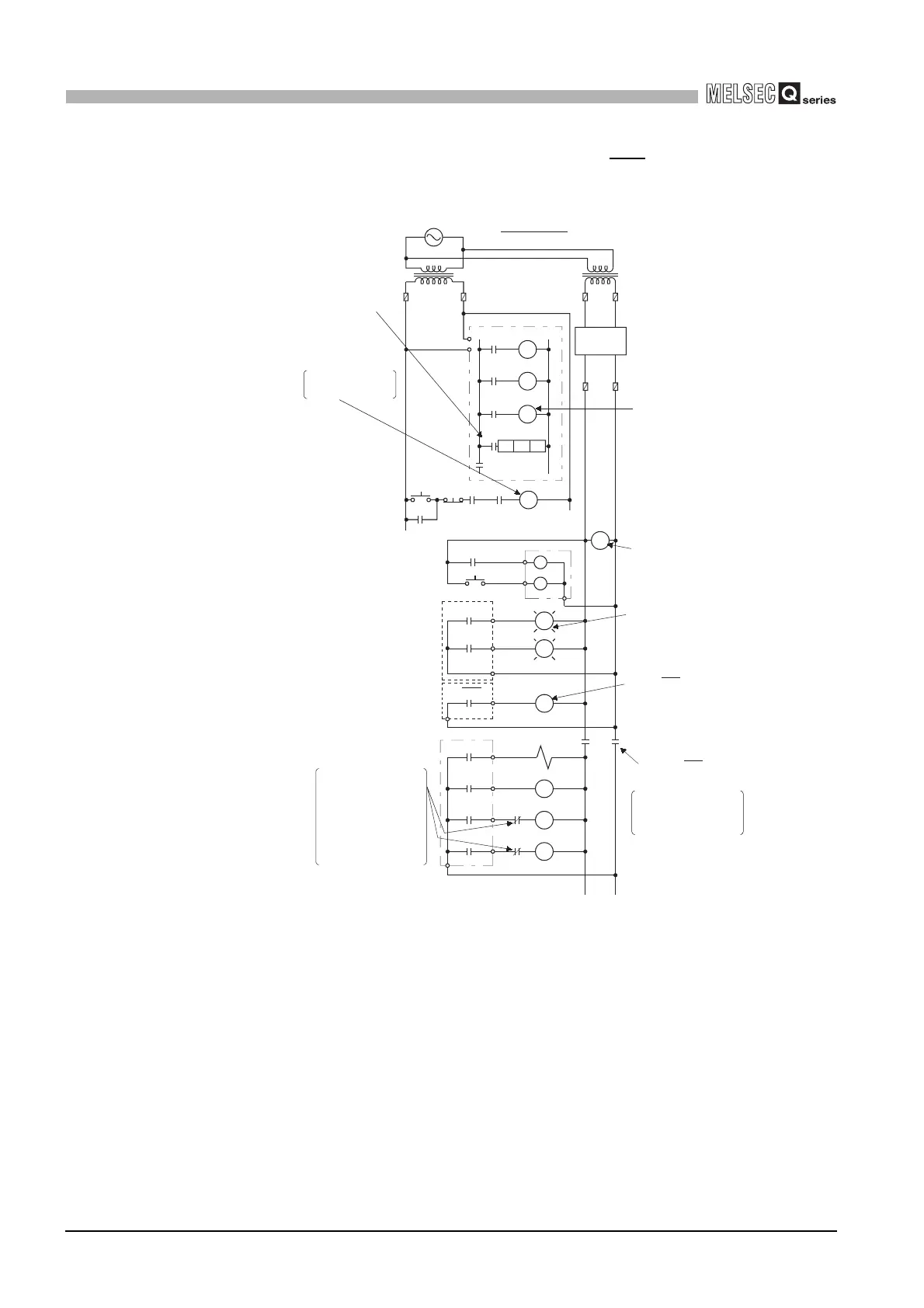

(2) System design circuit example (when using ERR terminal of power

supply module)

Diagram 10.2 System design circuit example

The power-ON procedure is as follows:

For AC/DC

1) Turn power ON.

2) Set CPU to RUN.

3) When DC power is established, RA2 goes ON.

4) Timer (TM) times out after the DC power reaches 100%. (The TM set value should be the period of time from when RA2

goes ON to the establishment of 100% DC voltage. Set this value to approximately 0.5s.)

5) Turn ON the start switch.

6) When the magnetic contactor (MC) comes on, the output equipment is powered and may be driven by the program. (If a

voltage relay is used at RA2, no timer (TM) is required in the program.)

MC

RA1

RA2

XM

Ym

MC2

MC1

M10

NO

MC MC

SM52

XM

TM

ERR

SM403

RA3

Yn

Power supply

FOR AC/DC

Input switched

when power supply

established.

RUN/STOP circuit

interlocked with RA1

(run monitor relay)

Power supply module

Interlock circuits as

necessary.

Provide external

interlock circuits for

conflicting operations,

such as forward rotation

and reverse rotation, and

for parts that could

damage the machine or

cause accidents if no

interlock were used.

Transformer

Fuse

Transformer

Fuse

CPU module

START SW

STOP SW

Program

Output module

Output module

DC power

Fuse

Set time for DC power

supply to be established.

Voltage relay is

recommended

Low battery alarm

(Lamp or buzzer)

OFF at ERR contact OFF

(stop error occurrence)

In the case of an

emergency stop or a

stop caused by a limit

switch.

MC

RA2

L

MC1

RA3

MC2

Ym

TM

MC1 NO M10

(-) (+)

Yn

RA1

Output by ERR contact OFF

Power OFF of equipment

Loading...

Loading...