10

LOADING AND INSTALLATION

10.6 Wiring

10.6.1 The precautions on the wiring

10 - 37

9

EMC AND LOW

VOLTAGE

DIRECTIVES

10

LOADING AND

INSTALLATION

11

MAINTENANCE AND

INSPECTION

12

TROUBLESHOOTING APPENDICES INDEX

This section describes the precautions for wiring power supply lines.

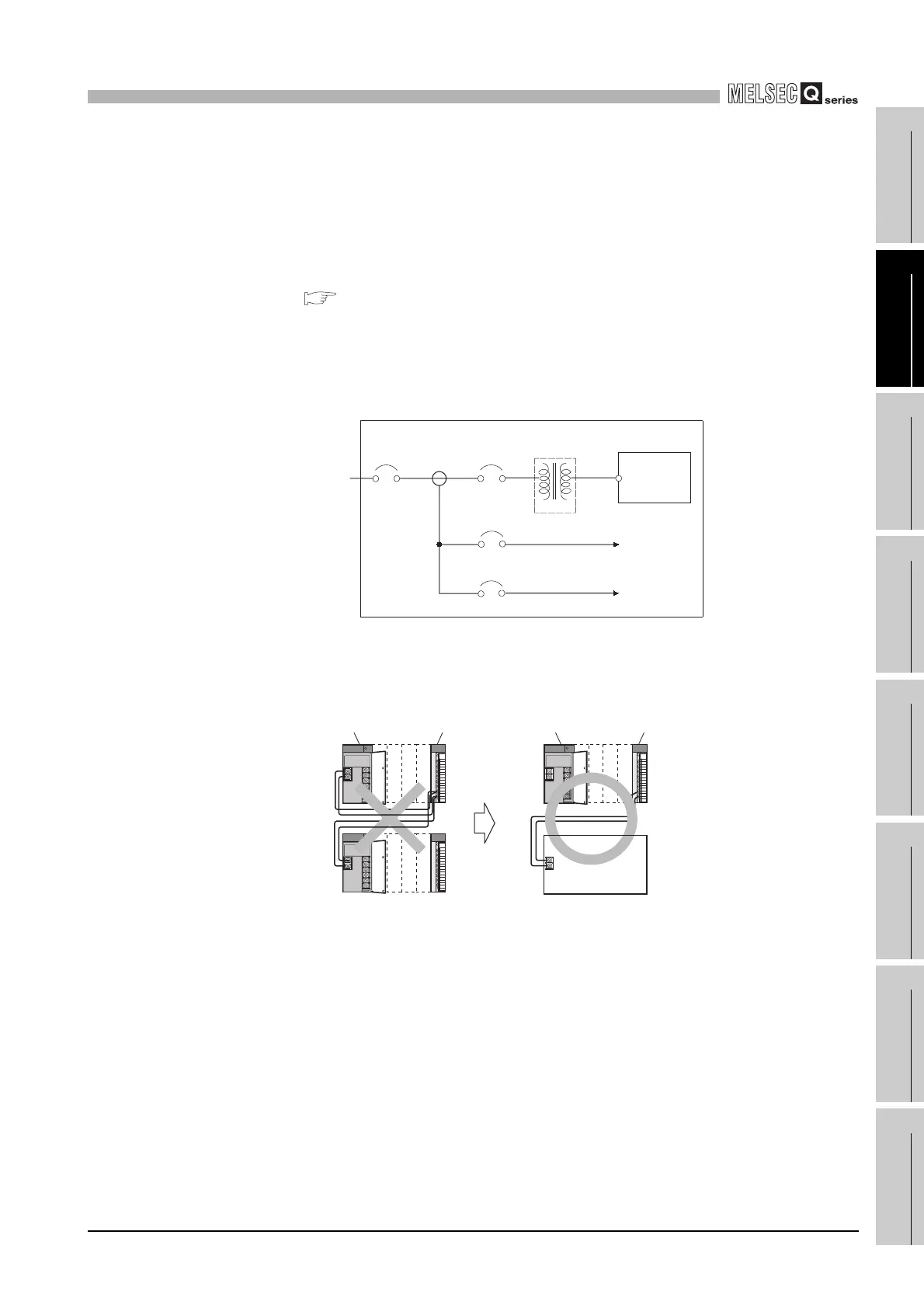

(1) Wiring power supply lines

• Wire the power supply lines for programmable controller, I/O devices, and motor

equipment separately as shown in Diagram 10.37.

• If there is much noise, such as lightning surge, connect an isolation transformer.

For details on the isolation transformer, refer to the following.

Section 9.1.6(3) Isolation transformer

• Taking rated current or inrush current into consideration when wiring the power

supply, be sure to connect a breaker or an external fuse that have proper blown

and detection.

When using a single programmable controller, a 10A breaker or an external fuse

are recommended for wiring protection.

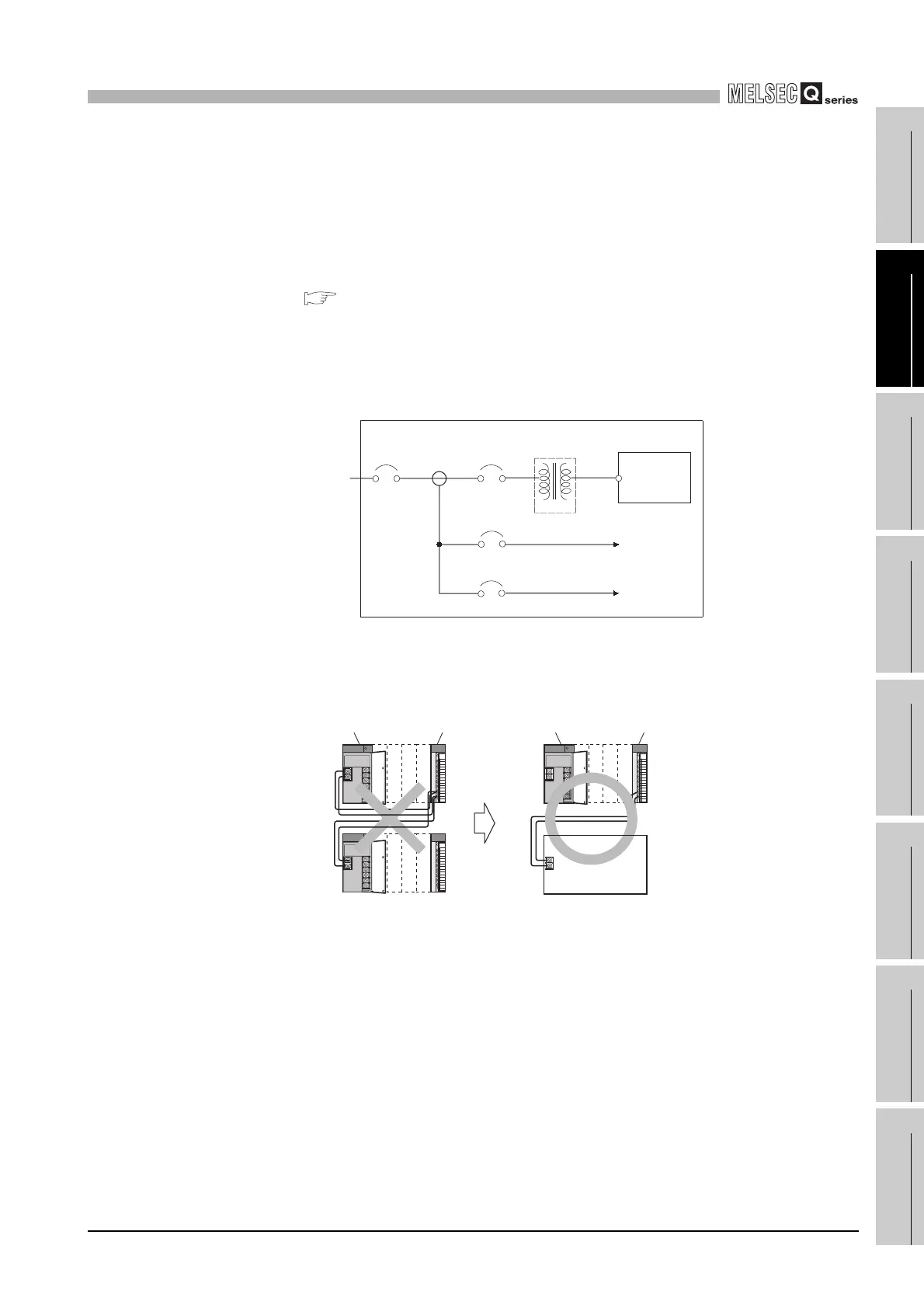

• Do not connect the 24VDC outputs of two or more power supply modules in

parallel to supply power to one I/O module. Parallel connection will damage the

power supply modules.

• 100VAC, 200VAC and 24VDC wires should be twisted as dense as possible.

Connect the modules with the shortest distance.

Also, to reduce the voltage drop to the minimum, use the thickest wires possible

(maximum 2mm

2

).

• Do not bundle the 100VAC and 24VDC wires with, or run them close to, the main

circuit (high voltage, large current) and I/O signal lines (including common line).

Reserve a distance of at least 100 mm from adjacent wires.

Diagram 10.37 Power supply wiring diagram

Diagram 10.38 Cautions when connecting a power supply module

100VAC

200VAC

T1

Main

power supply

Relay

terminal block

I/O power supply

I/O equipment

Inside a control panel

Programmable

controller power

supply

Isolation

transformer

Programmable

controller

Motor power supply

Motor equipment

Power supply module I/O module

DC24V

DC24V

Power supply module I/O module

DC24V

External power supply

Loading...

Loading...