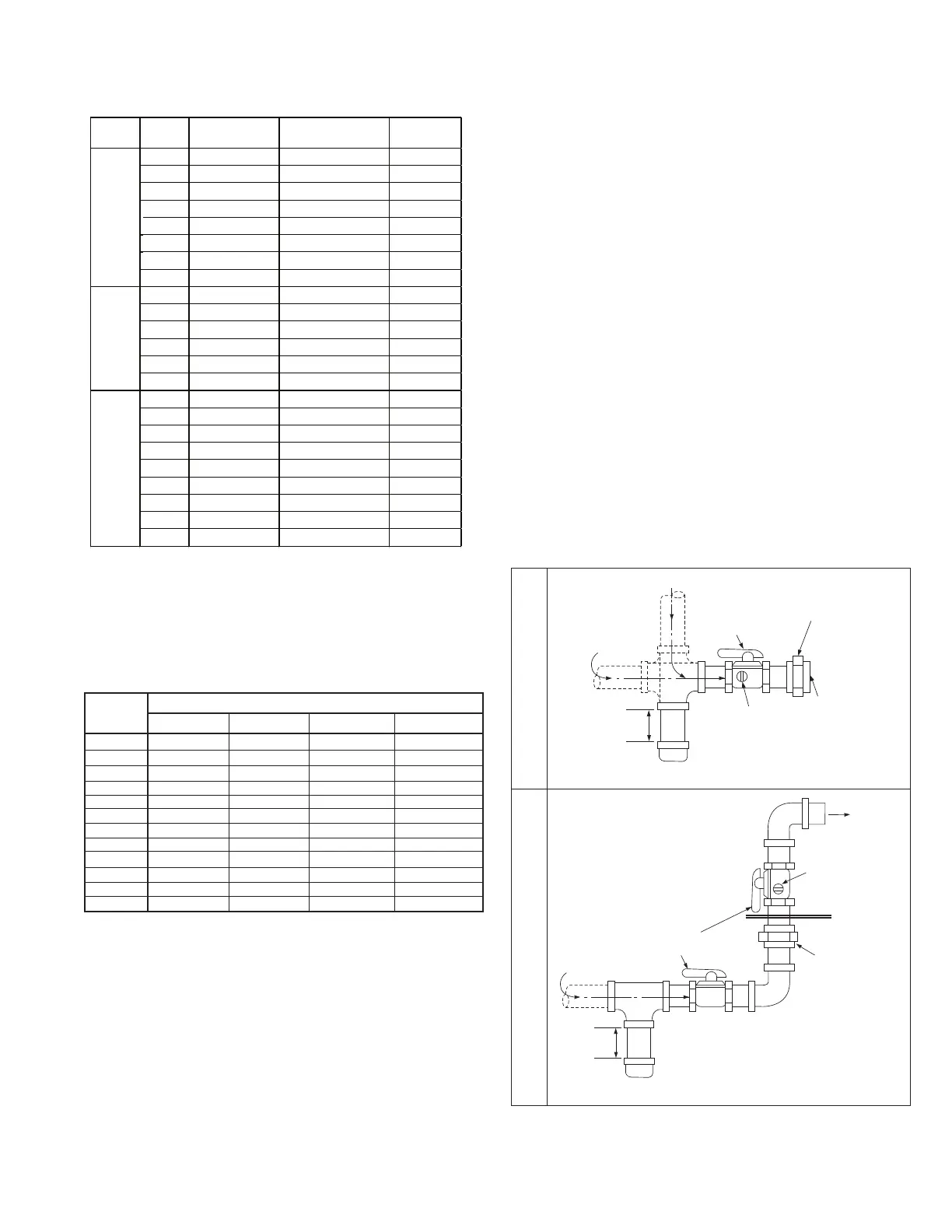

11MCP15-500.7

GROUND

JOINT

UNION

W/ BRASS

SEAT

3"

MIN.

TO

CONTROLS

MANUAL GAS

SHUT-OFF VALVE

GAS

SUPPLY LINE

SEDIMENT

TRAP

PLUGGED 1/8"

NPT TEST GAUGE

CONNECTION

Through hole

in bottom of unit.

(caulk hole to prevent

water leakage.)

Side Gas Connection

Bottom Gas Connection

Figure 11.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation

SUPPLY LINE

GAS

SUPPLY LINE

GROUND JOINT

UNION WITH

BRASS SEAT

MANUAL GAS

SHUT-OFF VALVE

3"

MIN.

SEDIMENT

TRAP

PLUGGED

1/8" NPT TEST

GAUGE CONNECTION

TO GAS

CONTROLS

j Valve is in the “OFF” position when handle is perpendicular to pipe.

j

GAS CONNECTIONS

3. The gas piping to the unit can enter the unit from the side

of the unit (refer to the unit dimensions) or from below (refer

to the base dimensions). A drill locator sticker and dimple is

located on the side of the unit to indicate the safe area for

drilling the hole for side gas pipe entry on B- and C-Cabinet

sized units. D-Cabinet sized units include a holes with

grommets for side pipe entry. Install a ground joint union

with brass seat and a manual shut-off valve external of the

unit casing, and adjacent to the unit for emergency shut-off

and easy servicing of controls, including a 1/8" NPT plugged

tapping accessible for test gauge connection (see Figure

11.1). Verify the manual shut-off valve is gas tight on an

annual basis.

NOTE: For bottom piped units, some local codes may require

a manual shutoff valve external to the unit casing. In this case,

the gas piping must exit the unit through the side, followed by

the manual shut-off valve, piped back into the unit side, and

lead to an additional union and manual shut-off valve.

4. Provide a sediment trap before each unit in the line where

low spots cannot be avoided (see Figure 11.1).

5. When Pressure/Leak testing pressures above 14" W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

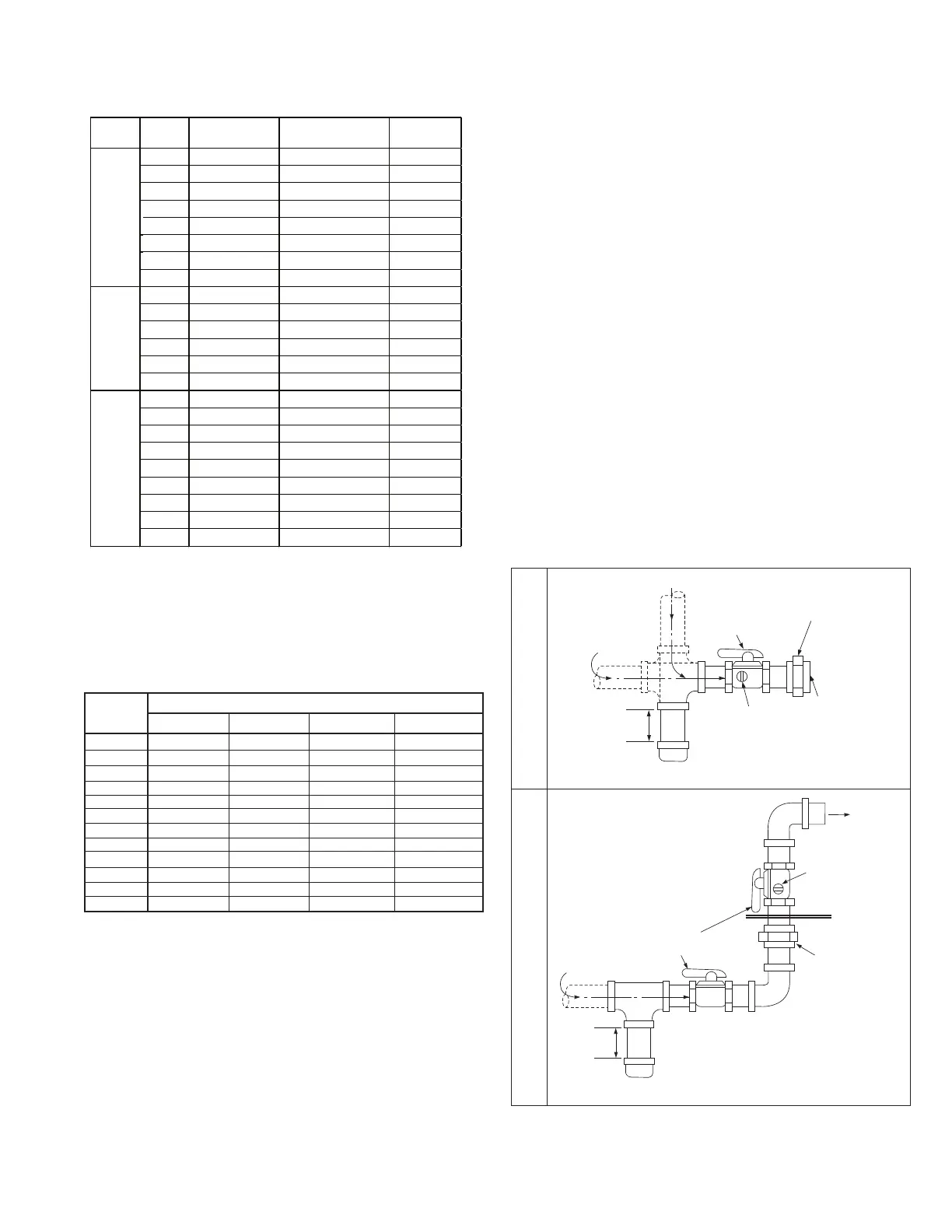

Table 11.1 - Natural Gas Heating Gas Consumption

j Natural gas consumption based on a heating value of 1050 Btu/cu. ft.

k C-Cabinet units consist of two furnaces that together total the value shown in

Table 11.1.

l D-Cabinet units consist of two furnaces that together total the value shown

in Table 11.1 for sizes up to 800,000 Btu/hr. For sizes over 800,000 Btu/hr,

the unit consists of four furnaces that together total the value shown in Table

11.1.

Digit 6 Digit 18

F 150,000 143 1/2"

G 200,000 190 3/4"

H 250,000 238 3/4"

J 300,000 286 3/4"

K 400,000 381 3/4"

R 175,000 167 1/2"

S 225,000 214 3/4"

T 310,000 295 3/4"

J 300,000 286 3/4"

K 400,000 381 1"

L 500,000 476 1"

L 600,000 571 1"

U 350,000 333 1"

V 450,000 429 1"

K 400,000 381 1.5" x 2

L 500,000 476 1.5" x 2

M 600,000 571 1.5" x 2

Q 800,000 762 1.5" x 2

1 900,000 857 1.5" x 2

2 1,000,000 952 1.5" x 2

3 1,200,000 1143 1.5" x 2

4 1,400,000 1333 1.5" x 2

5 1,600,000 1524 1.5" x 2

C

B

D

m Gas pipe capacities based on gas pressure up to 14" W.C. through Schedule

40 pipe with a pressure drop of 0.3" W.C. for Natural gas with a specific

gravity of 0.60.

Pipe

Length

(feet)

Gas Pipe Diameter

1" 1-1/4" 1-1/2" 2"

10 520 1050 1600 3050

20 350 730 1100 2100

30 285 590 890 1650

40 245 500 760 1450

50 215 440 670 1270

60 195 400 610 1150

70 180 370 560 1050

80 170 350 530 990

90 160 320 490 930

100 150 305 460 870

125 130 275 410 780

150 120 250 380 710

Table 11.2 - Gas Pipe Capacities (Cu. Ft. per Hour) m

Loading...

Loading...