14 MCP15-500.7

Condensate Drain and Trap Installation

(Condensing Furnace Type Only)

For Condensing furnace types, as determined from Table 12.1

on page 12, during heating operation, condensate is produced

in the furnace sections. The installation requires condensate

drain systems from each furnace section, as shown in Figures

14.1 and 14.2 and described below. Condensate trap kits are

provided with the unit.

1. For proper heating system performance, the condensate

drain system must include a trap for each furnace.

B-Cabinet units have one furnace while C-Cabinet units

have two furnaces.

2. All joints must be watertight to prevent leakage of

condensate. The drains must be extended down through

the base of the unit and into the heated space below.

3. Each heat exchanger drain assembly includes a threaded

elbow that is oriented down. Once the male threaded PVC

adapters, included with the kit, are glued to the PVC drain

pipe (by others) that extends into the space, they are to be

routed up through the holes in the unit base pan and

screwed into the elbow connections. The threads must be

sealed to prevent leaks.

4. Unions are recommended to permit maintenance of the

drains and to facilitate service of the heater. A union is

shown on both sides of each trap.

5. A vacuum breaker is required after each trap. The vacuum

breaker should be constructed so that dirt and debris do

not enter and clog the drain system.

6. Local code permitting, the condensate drain systems may

be joined after the traps and connected to a sanitary drain

within the building. Because the condensate produced is

acidic, some municipalities may require that the

condensate be neutralized before being discharged into the

sanitary sewer. A condensate neutralizer tube kit is

available from Modine to reduce the pH of the condensate.

A single tube can be used for drains that are joined after

the traps providing the tube is installed after the junction.

Refer to the instructions that come with the kit.

7. For proper operation, the traps must be primed with water.

The traps must be installed with the higher side connected

to the heater and the lower side connected to the drain.

8. If there is an opportunity that the temperature in the space

will fall below freezing during non-operating periods, the

condensate drain systems and secondary heat exchanger

must be completely drained to prevent freeze damage.

Alternately, heat tape can be applied to the drain pipe

system in accordance with the heat tape manufacturers

instructions.

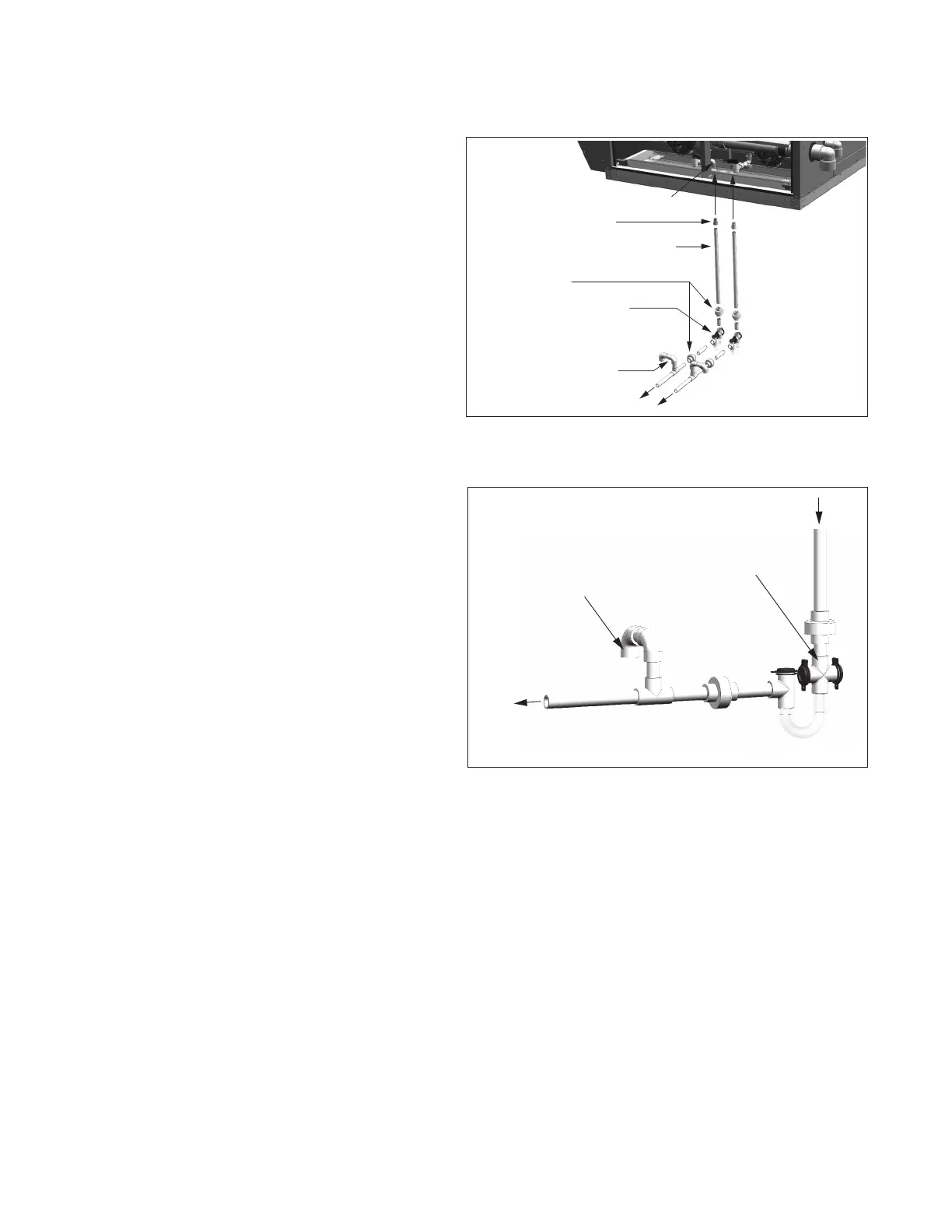

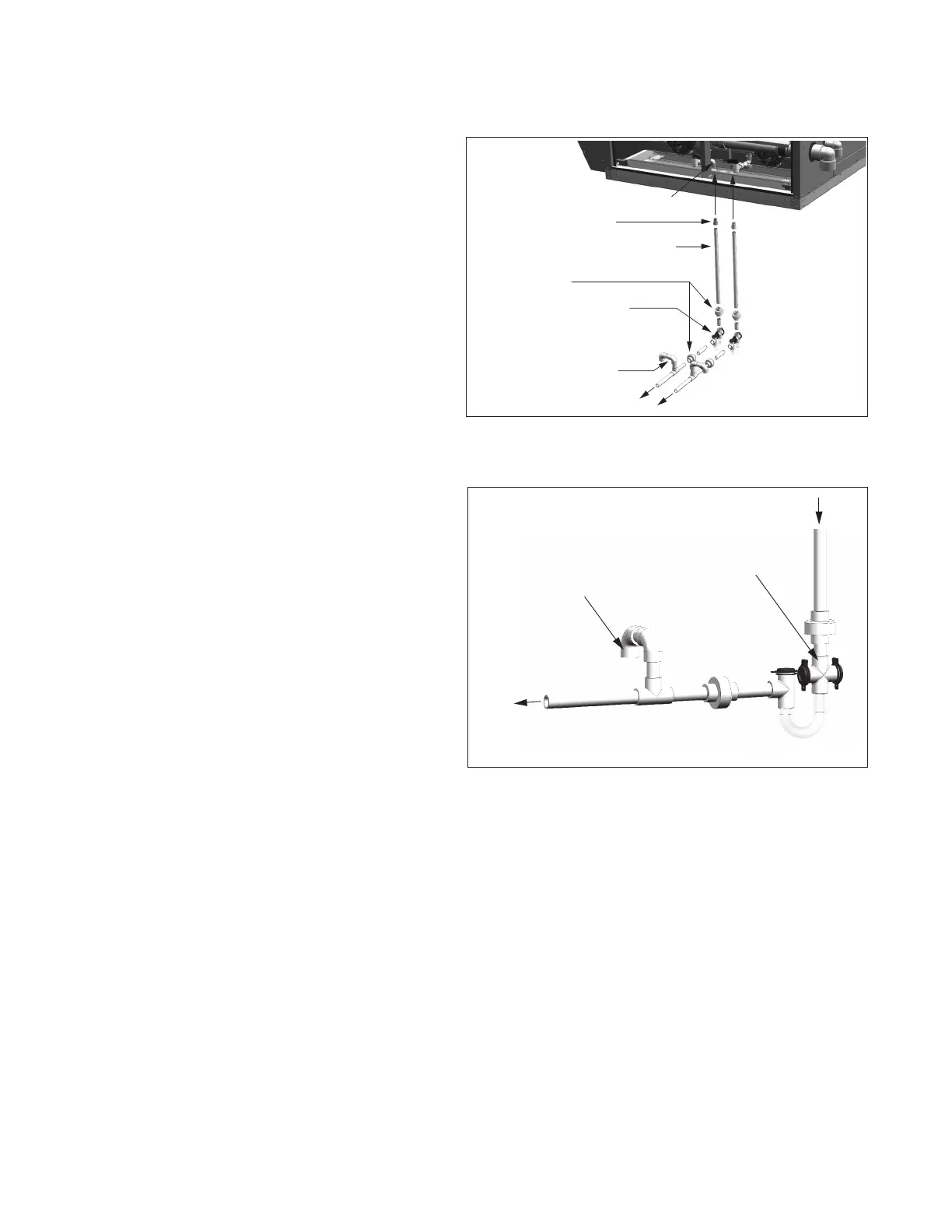

Figure 14.2 - Drain System Trap/Vacuum Breaker

Figure 14.1 - Furnace Condensate Drain/Trap

System j

3/4" Threaded Elbow on Heat Exchanger Drain

Assembly (included with kit)

3/4" Male Threaded PVC Adapter

(included with kit)

3/4" PVC Pipe (by others) with Sufficient Length

to Reach the Heat Exchanger Drain Assembly

from the Inside of the Building

3/4" Unions (by others)

Recommended for Ease of Future Service

PVC "EZ-Trap" (included with kit) for

Proper Drain Trapping (a 3/4" to 1" bushing

by others may be required)

Note: The trap must be located in a heated

space or protected to avoid freezing.

Vacuum Breaker and Drain Piping

Components (by others)

To Building

Drain System

j C-Cabinet sized unit shown with two condensate drain systems. B-Cabinet

sized units require only one drain system.

Note: Drain pipe from unit

must enter the high side of

the drain trap.

Note: Refer to figure above for determination of parts supplied by others.

Vacuum Breaker

Exchanger Drain

Assembly on Unit

To Building

Drain System

GAS HEATING OPTION CONDENSATE DRAIN AND TRAP INSTALLATION

Loading...

Loading...