19MCP15-500.7

START-UP PROCEDURE - CONTINUED

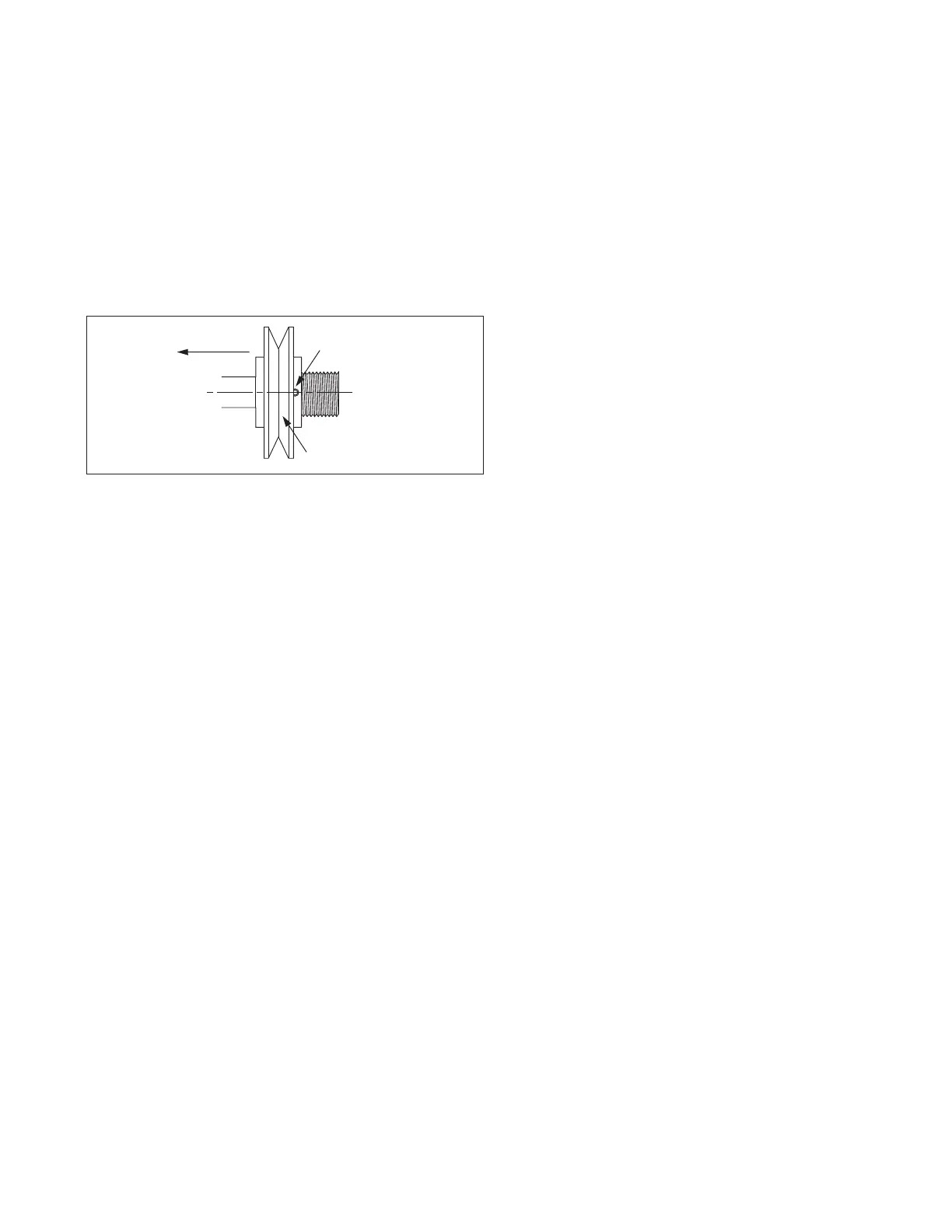

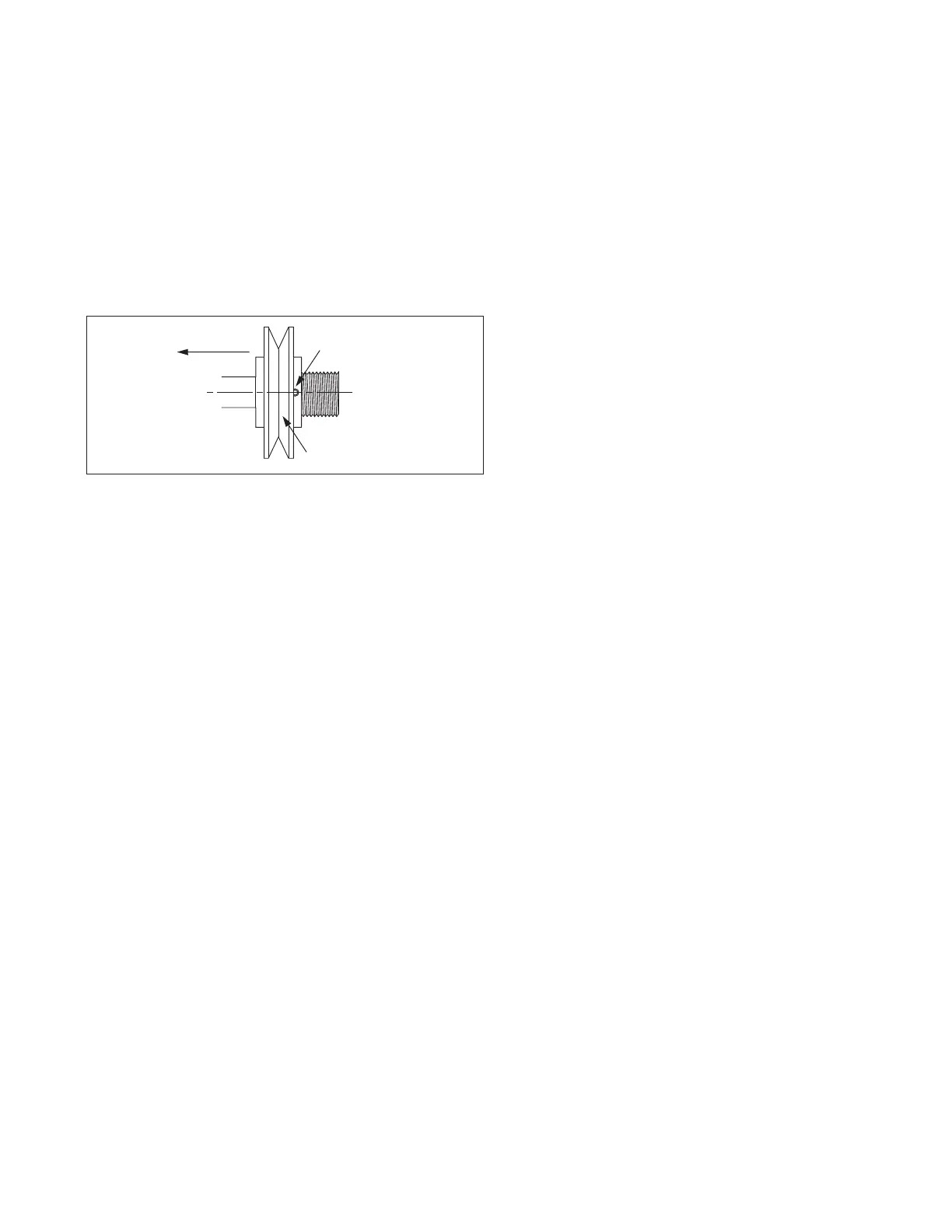

Toward Motor

Set Screw

Adjustable Half

of Sheave

Figure 19.1 - Motor Sheave Adjustment

Blower Adjustments – Belt Drive Fans

All belt drive supply fan and, if applicable, exhaust fan speed

adjustments can be made with the adjustable sheave on the

blower motor as follows:

1. Turn off power to the unit at the disconnect switch. If

equipped with gas heat option, turn all hand gas valves to

the “OFF” position.

2. Loosen the belt tension and remove the belt.

3. On the motor sheave, loosen the set screw on the side

away from the motor (see Figure 19.1).

4. To increase the blower speed, turn the adjustable half of

the sheave inward. To decrease the blower speed, turn the

adjustable half of the sheave outward. The sheave half is

adjustablein½turn(180°)increments.Each½turn

represents approximately a 2-5% change in blower speed

and airflow volume.

5. Tighten the set screw on the flat portion of the sheave shaft.

6. Replace the belt and verify that the belts are aligned in the

sheave grooves properly and are not angled from sheave

to sheave.

7. Turn on power to the unit and initiate blower motor

operation. For guidance, refer to the Controls Manual.

8. Check the motor amps to ensure the maximum motor amp

rating is not exceeded. Verify airflow volume and repeat

steps above for further adjustment.

9. If equipped with gas heat, turn on the gas and initiate burner

operation. For guidance, refer to the Controls Manual.

10. Verify the temperature rise and supply air temperature of

the heating section do not fall outside the range or exceed

the maximums shown in Table 18.1. Airflow can be

approximated with the following formula:

CFM = (Input Btu/hr x Eff) / (1.08 x Temp Rise)

where Eff (Efficiency) is determined from Table 18.1

11. After 24 hours of operation, retighten the setscrews to the

torque listed in the owners manual on the bearing, sheave,

and blower wheel to avoid damage to the unit.

Air Flow Proving Switch / Optional Dirty Filter Switch

The air flow proving switch is factory installed in the blower

compartment. The purpose of the air flow proving switch is to

cut power to the controls if a positive pressure is not measured

by the switch. This could be caused by a lack of air movement

through the evaporator coil or heat exchanger.

The optional dirty filter pressure switch is factory installed in

the filter section. The dirty filter pressure switch monitors the

pressure differential between the two sides of the filters. When

the filters become dirty, the differential pressure increases and

trips the pressure switch which initiates an alarm from the Carel

controller. The pressure differential switch must be field set

because setting the switch requires the blower to be inoperation

and the ductwork to be installed.

Setting the Air Flow Proving or Dirty Filter Switch

1. Ensure that the unit filters are clean. Replace if necessary.

2. Using the Modine Control System controller interface, start

blower operation.

3. Turn the set screw of the pressure switch clockwise until it

stops.

4. With the wires removed from the common and normally

open terminals of the switch, measure continuity and turn

the adjustment screw counter-clockwise until the switch

makes. Then turn the adjustment screw one additional turn

counter-clockwise to account for dirty filters or other system

static changes.

Variable Air Movement Applications

Units may be supplied with variable frequency drives for

applications where variable air volume is required. The

minimum air flow may be varied between 50 and 100% of the

full speed air flow depending on the controls selection of the

unit, but never less than the following:

• B-Cabinet units: 1100 CFM

• C-Cabinet units: 3000 CFM

• D-Cabinet units: 4000 CFM

• All units with Gas Heat: Minimum airflow as listed on the

Gas Heat Serial Plate

Refer to the Controls Manual for additional information.

Loading...

Loading...