18 MCP15-500.7

START-UP PROCEDURE - CONTINUED

Blower Adjustments – Direct Drive Fans

All direct drive supply fan speed adjustments can be performed

with the Modine Control System programmable microprocessor

controller. There are two ways to access the menus:

1. Using the user interface on the main unit controller.

2. Using the pGD1 Digital Display/Interface Module.

For guidance on either method above, refer to the latest

revision of the following documents for additional warnings,

cautions, controller location, instructions, and menu navigation:

• ControlsManual,MCP15-525.

• pGD1DigitalDisplay/InterfaceModuleInstallation

Instructions, MCP15-543.

The blower adjustments are made as follows:

1. Ensure unit is running at the maximum airflow setting for

the control type selected. For example, if the unit has

Multi-Speed or Variable Speed fan control, ensure the unit

is operating at the highest speed setting.

2. On the keypad navigate to menu “G. Service -> f.

SERVICE SETTINGS”. At this menu, you will be prompted

to enter the Service password of 1500.

3. Navigate to “c. Control Settings” and scroll to the “Supply

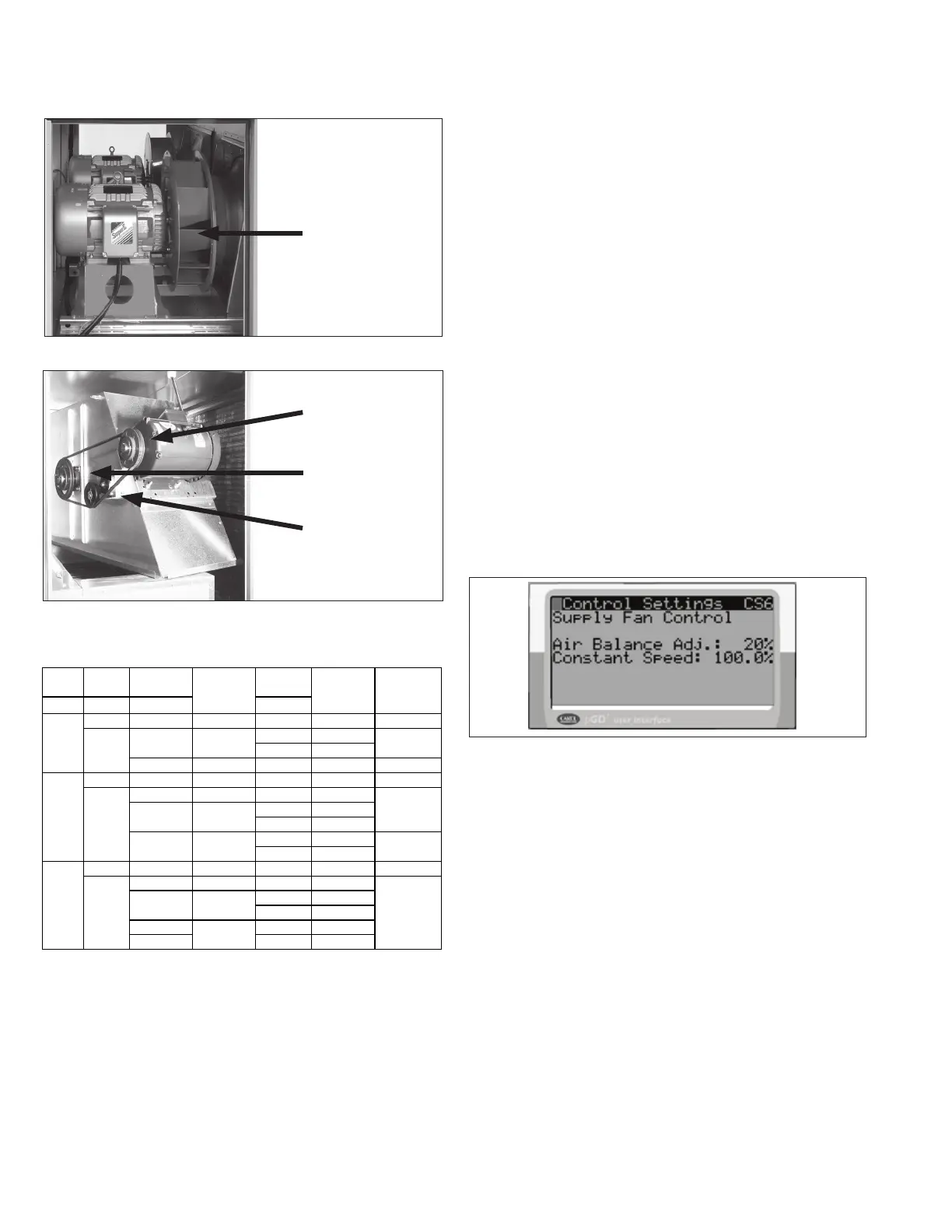

Fan Control (CS6)” screen. See Figure 18.3.

4. Adjust the Air Balance Adj parameter up or down to obtain

the design airflow given the actual static pressure.

5. In the event you are unable to increase or decrease the

motor speed to the desired air balance please consult your

factory representative.

6. Check the motor amps to ensure the maximum motor amp

rating is not exceeded. For units equipped with a VFD,

measure the amps at the incoming lines to the motor. If

the unit has dual supply fans, measure each motor

individually. Verify airflow volume and repeat steps above

for further adjustment.

7. If equipped with gas heat, turn on the gas and initiate

burner operation. For guidance, refer to the Controls

Manual.

8. Verify the temperature rise and supply air temperature of

the heating section do not fall outside the range or exceed

the maximums shown in Table 18.1. Airflow can be

approximated with the following formula:

CFM = (Input Btu/hr x Eff) / (1.08 x Temp Rise)

where Eff (Efficiency) is determined from Table 18.1

Figure 18.3 - Control Settings Screen CS6

Table 18.1 - Allowable Temperature Rise Range and

Maximum Supply Air Temperature

Casing

Size

Heat

Type Rating

Eff

(for formula)

Temp Rise

Allowable

Temp Rise

Range

Max Supply

Air TempDigit 6 Digit 17 Digit 18 Digit 19

B

1 A, B, C, D 1.00 N 1 - 100°F 100°F

2 or 3

F, G, H, J, K 0.81

L 30 - <70°F

130°F

H 70 - 100°F

R, S, T 0.94 N 30 - 100°F 100°F

C

1 A, B, C, D, E 1.00 N 1 - 100°F 100°F

2 or 3

J 0.81 N 30 - 75°F

130°F

K, L, M 0.81

L 30 - <70°F

H 70 - 100°F

U, V 0.81

L 30 - <70°F

100°F

H 70 - 100°F

D

1 A, B, C, D, E 1.00 N 1 - 100°F 100°F

2 or 3

K 0.81 L 30 - 75°F

130°F

L, M, Q 0.81

L 30 - <70°F

H 70 - 100°F

1, 4

0.81

H 70 - 120°F

2, 3, 5 H 60 - 120°F

Figure 18.2 - Belt Drive Blower Example

Figure 18.1 - Direct Drive Blower Example

Direct Driven Blower

(dual blower shown)

Motor Sheave

(adjustable)

Blower Sheave

(non-adjustable)

Automatic Belt

Tensioner

Loading...

Loading...