7MCP15-500.7

DUCT INSTALLATION AND UTILITY CONNECTIONS

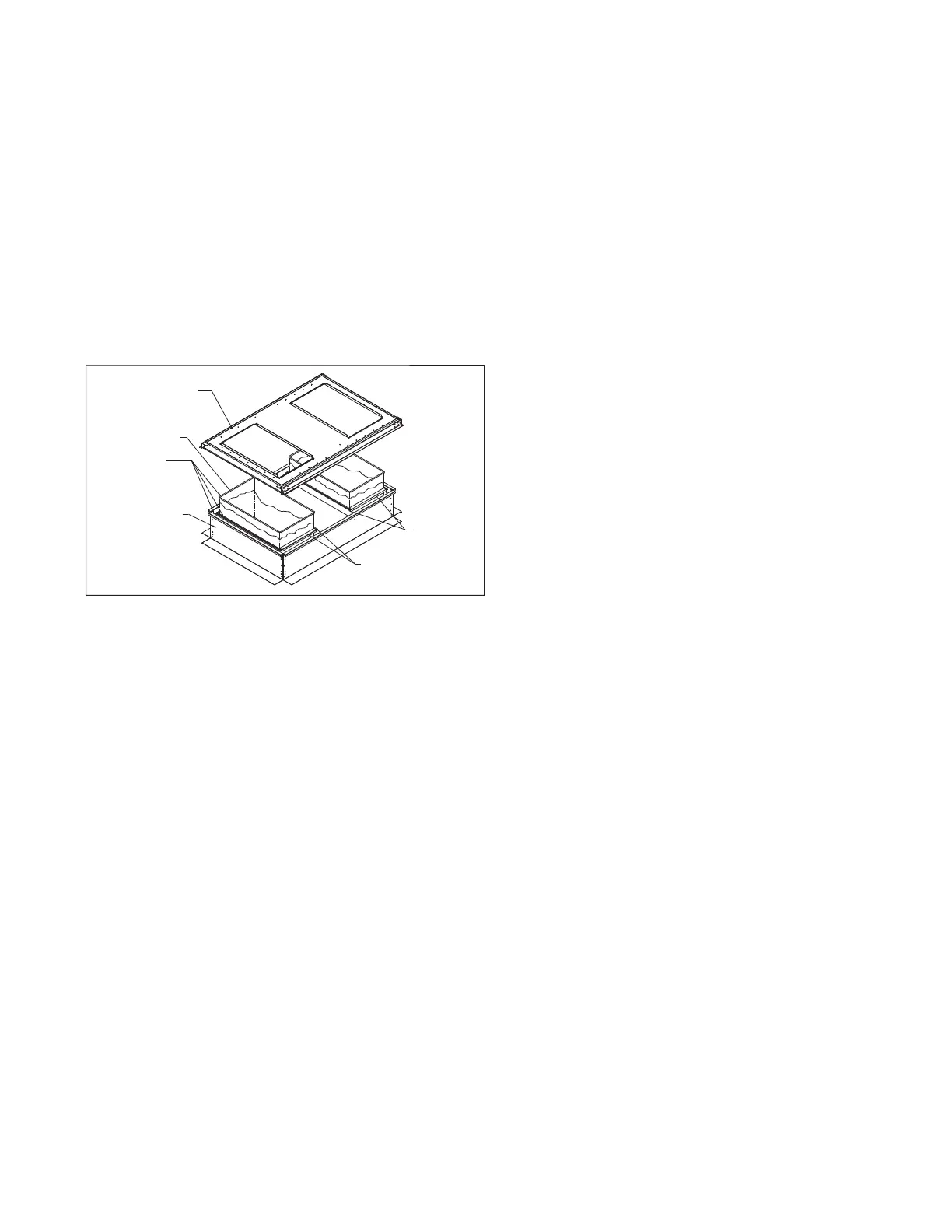

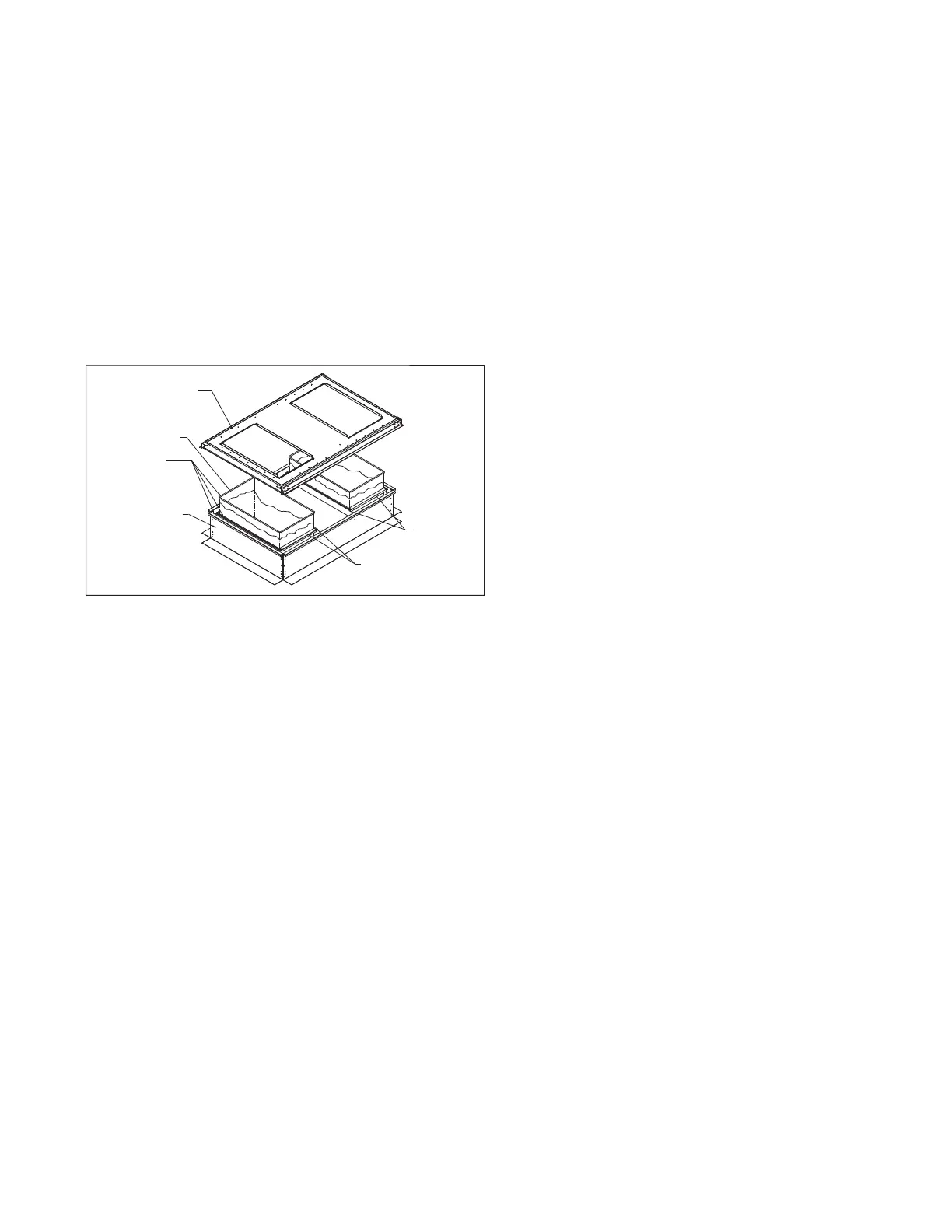

Figure 7.1 - Discharge and/or Return Air Connectors

5. To assure proper air flow from the unit, follow these duct

design recommendations:

a. Be sure ducts are properly sized and installed.

b. As a general rule, all discharge ducts should have a

straight run of at least three (3) hydraulic duct diameters

before making turns in the ductwork.

Hydraulic Duct Diameter for Rectangular Ducts = 4A/P

Hydraulic Duct Diameter for Circular Ducts = D

where:

A = Cross Sectional Area of Rectangular Duct

P = Perimeter of Rectangular Duct

D = Diameter of Round Cut

c. Wherever turns in the duct work are made, include

turning vanes.

d. Supply air ducts in a “T” configuration should be

avoided to prevent air temperature stratification. If this

configuration must be used, provide appropriate mixing

devices and/or the necessary straight duct length before

the “T” to provide uniformly mixed air temperature

delivery to both supply air duct trunks.

Utility Connections

Utility and control connections can be made to the unit from

the bottom or through the fixed side panels. Holes can be field

drilled in fixed side panels to accommodate utility connections

as shown on the unit dimensional drawings and the utility

entrance location area label located on the unit. All gas and

electrical connections to the unit must be weatherized so they

are watertight.

RETURN AIR

CONNECTOR

DISCHARGE AIR

CONNECTOR

90° FLANGED

DUCTWORK

(By Installer)

UNIT BASE

(Shown without

unit for clarity)

ROOF

CURB

BEFORE UNIT

INSTALLATION

CAULK ALL MATING

SURFACES ➀

(Caulk by installer)

➀ If roof curb is supplied

by Modine, full perimeter

gasket material is supplied

and caulking is not necessary.

Duct Installation

1. The unit is designed to accept 90° flanged ductwork on both

the supply and return air openings. Refer to the roof curb or

the unit base dimensional drawings to determine the location

of the openings.

2. Acoustic duct liners are recommended on all internal supply

and return air ducts.

3. When ductwork is installed prior to unit arrival, flexible

connections should be included to make connections easier

and to simplify possible future service.

4. When a roof curb is used in conjunction with factory supplied

discharge and/or return air connectors, the ductwork can be

fastened to the connectors prior to the unit installation. The

connectors will accept 90° flanged ductwork (see Figure 7.1).

Loading...

Loading...