E-PAK 500EN

34

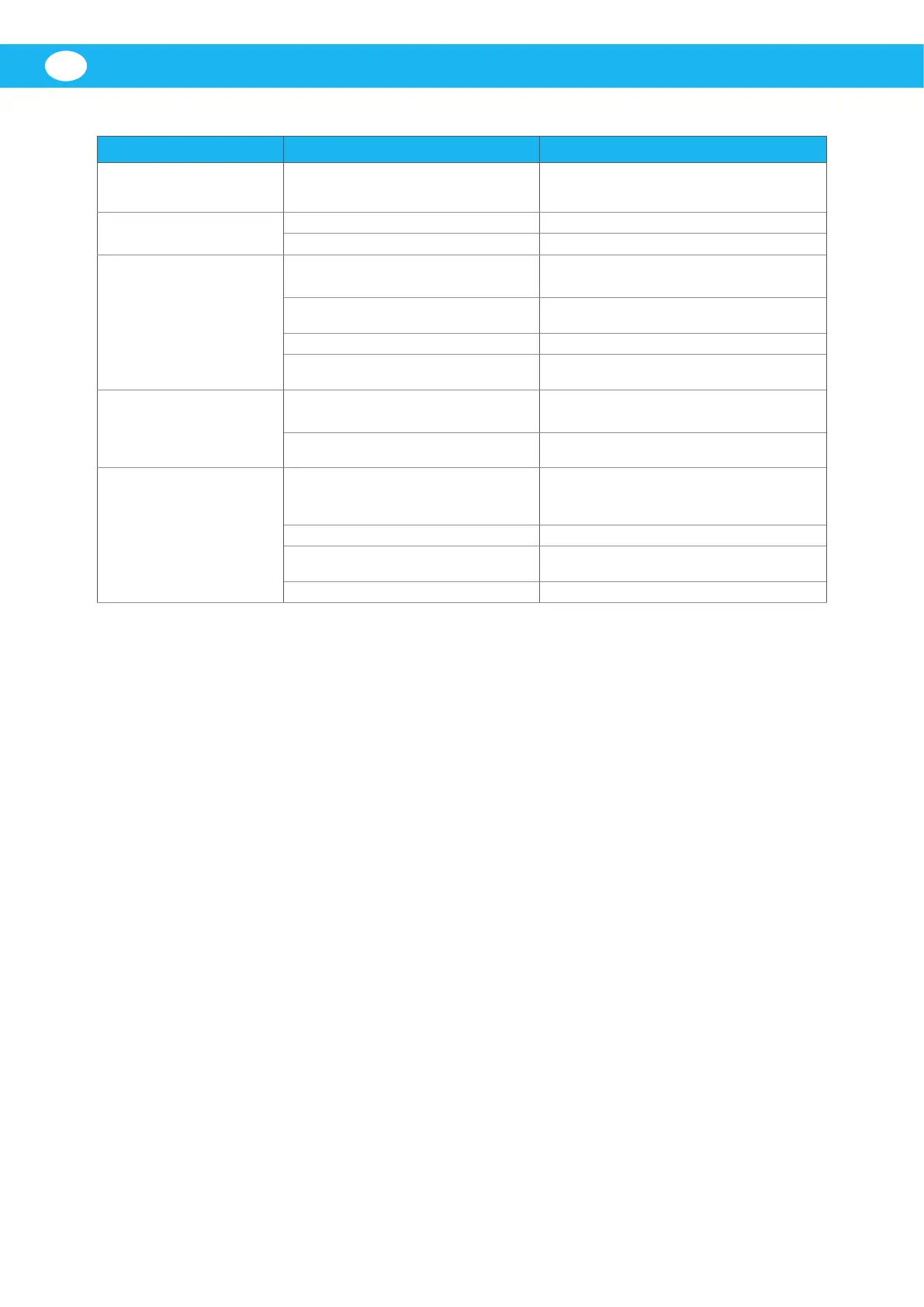

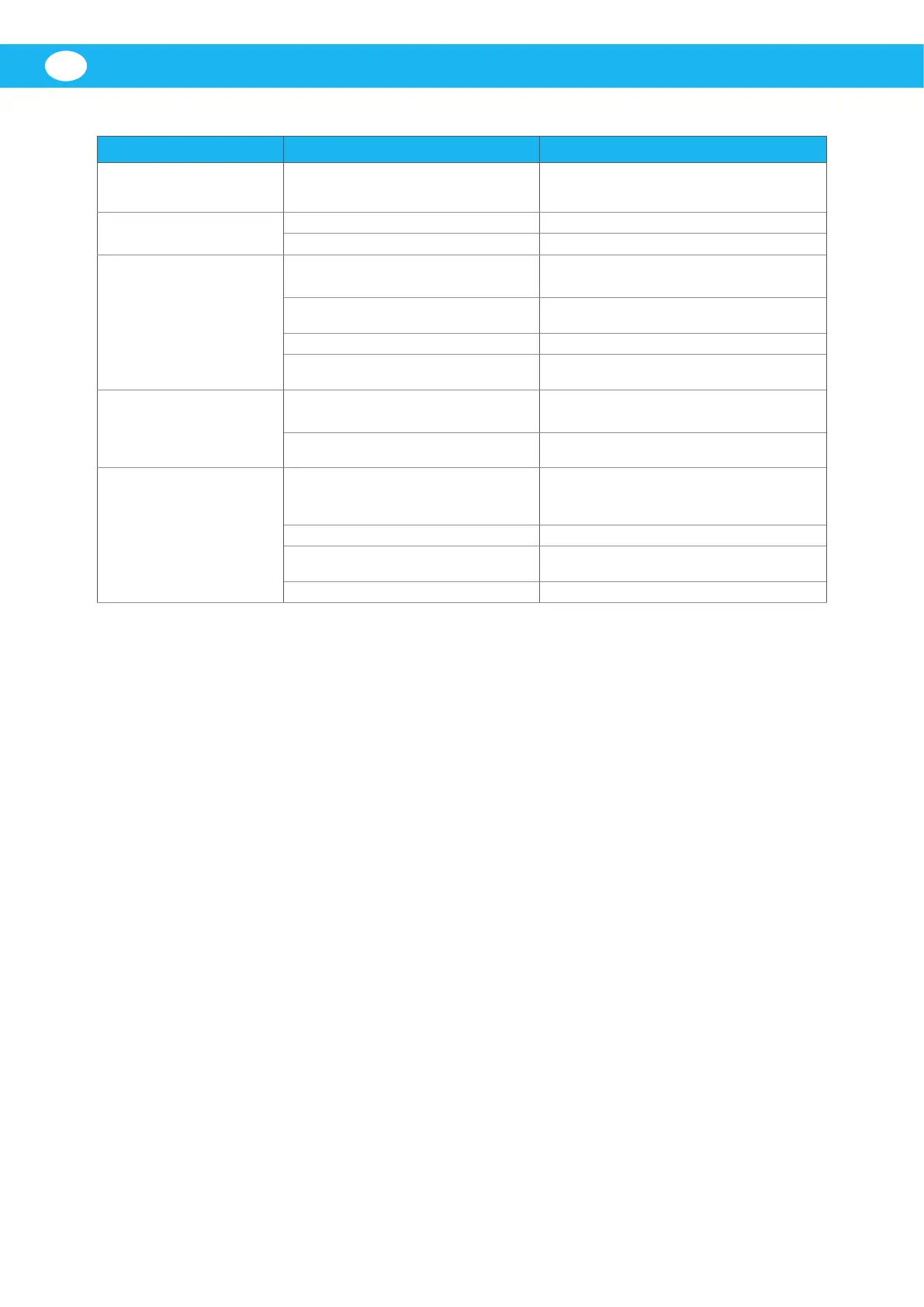

Table 11-1: Trouble shooting guide

Error Possible cause Solution

Unitstartswithoutanyvalveat

anyworkstationbeingopened.

The PS cable is short-circuited. Disconnect the cable from the starter and use an

ohmmeter across the leads in turn to locate the

fault.

No dust is collected in the

collector bin.

Filtercleaningdoesnotwork. See Chapter ‘9 Maintenance’.

Insignicantowonthewaytotheunit. See‘Lowvacuumorairow’.

Lowvacuumorairow. Depositsorblockageinductsontheway

to the unit.

• Clean the ducts.

• Check the transport velocity.

The duct system is not properly

dimensioned.

Re-dimension the duct system or add an extra

suction source.

Valvesintheductsystemarenotworking. Check the duct system valves.

Theltercleaningdoesnotworkoris

insucient.

Checkthefunctionoftheltercleaning.

Filtercleaningdoesnotwork. Thecompressedairpressureorowistoo

low.

• Adjust the pressure.

• Check the hose dimension.

The solenoid valve is not connected

properly.

Check the valve and air pressure.

The air lines, valve and/or cylinder are

blocked.

• Clean or replace the air lines, valve and/or

cylinder.

• Filter incoming compressed air.

Thecylinderand/orvalvedoesnotwork. Replace the cylinder and/or valve.

Dust is hard to clean, normal cleaning does

notwork.

Contact your nearest authorized distributor or

Nederman for technical advice.

The cleaning interval is too short. Extend the cleaning interval.

12 Acronyms and abbreviations

CAS

Compressed air switch

DIR

Duty/idle relay

DPS

Differential pressure switch

FCR

Filter cleaning relay

NL

Normal litres

PE

Protective earth

PS

Pilot signal

SSR

Start/stop relay

TS

Thermal switch

SSR

Start/stop relay

Loading...

Loading...