• Wherever the unit is located, walls to sound sensitive

rooms should be fitted with sound insulation.

• Route pipes so they are not fixed to an internal wall

that backs on to a bedroom or living room.

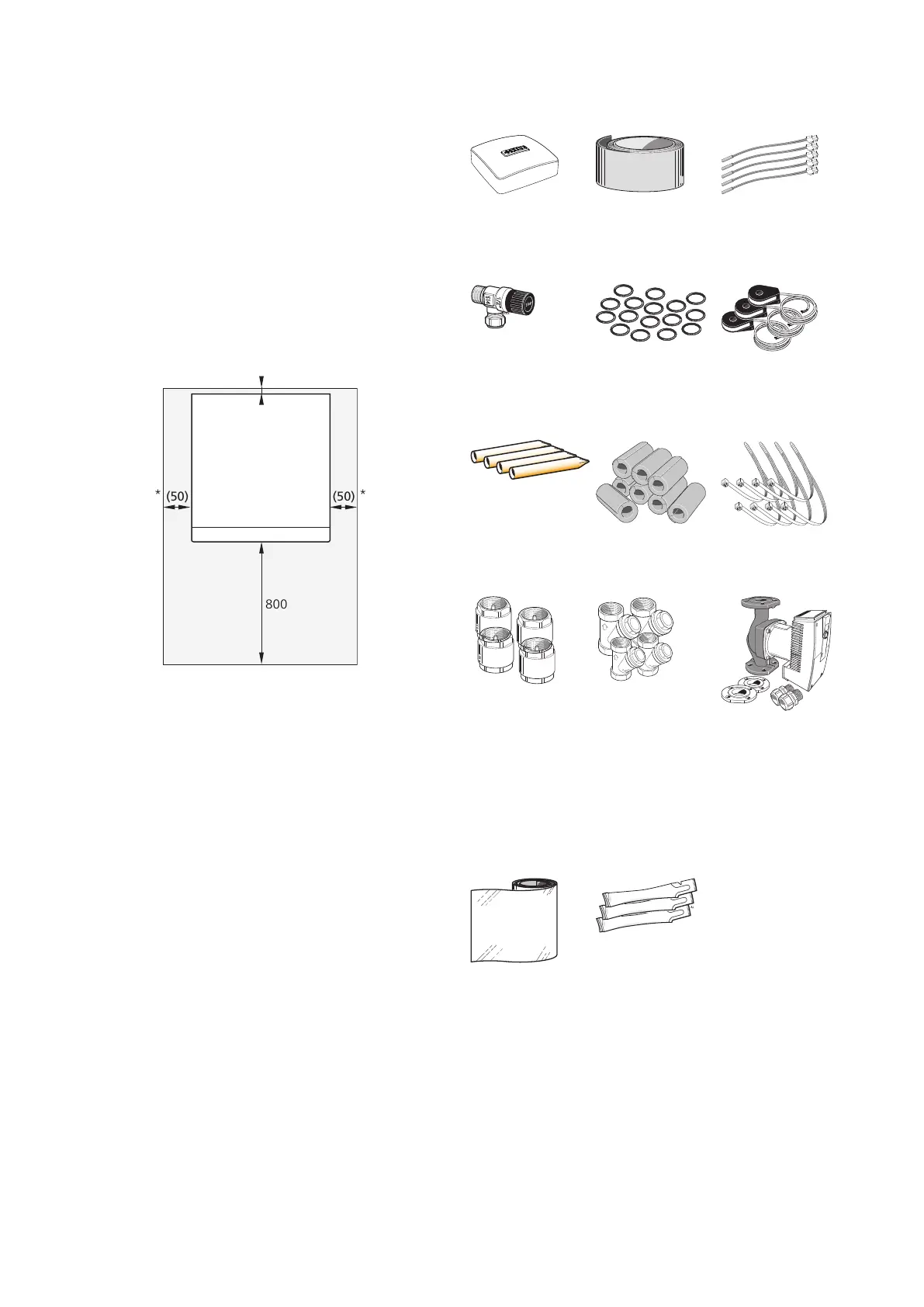

INSTALLATION AREA

Leave a free space of 800 mm in front of the product.

Approx. 50 mm free space is required on each side, to

remove the side panels (see image). The panels do not

need to be removed during service. All service on F1345

can be carried out from the front. Leave space between

the heat pump and the wall behind (and any routing of

supply cables and pipes) to reduce the risk of any vibra-

tion being propagated.

* A normal installation needs 300 – 400 mm (any side) for connection

equipment, valves and electrical equipment.

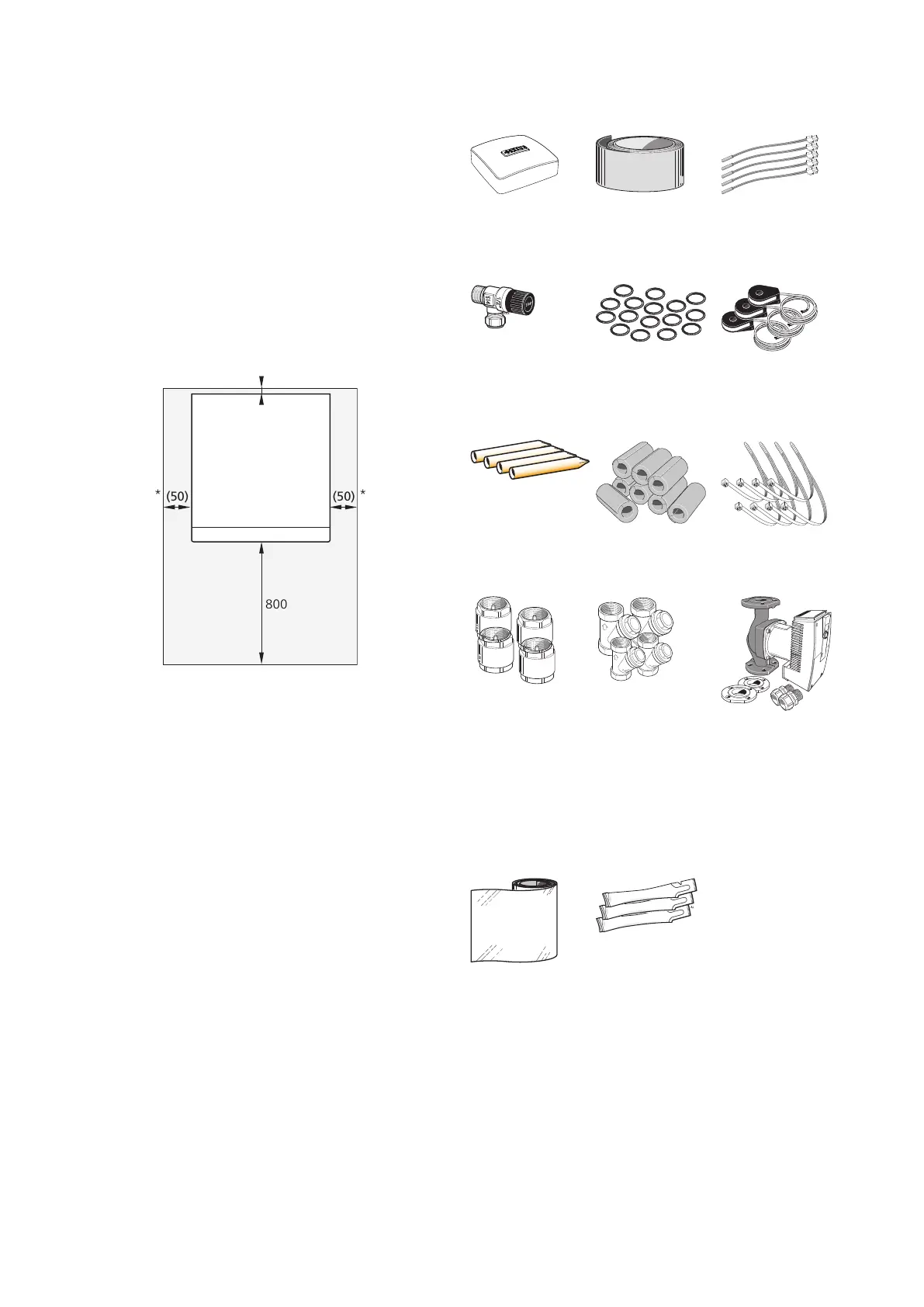

Supplied components

Temperature

sensor

5 x

Insulation tape

1 x

Outdoor temperat-

ure sensor

1 x

Current sensor

(not 60 kW)

3 pcs

O-rings

16 x

Safety valve

0.3 MPa (3 bar)

1 x

Cable tie

8 x

Pipe insulation

8 pcs

Tubes for sensors

4 x

External brine

pump

(only for 40 and

60 kW)

1 x

WILO

LEK

LEK

WILO

WILO

2,5(22)

H - 50 - 2,5

TUV-SV-97-525

WILO

LEK

LEK

WILO

WILO

2,5(22)

H - 50 - 2,5

TUV-SV-97-525

WILO

LEK

LEK

WILO

WILO

2,5(22)

H - 50 - 2,5

TUV-SV-97-525

WILO

LEK

LEK

WILO

WILO

2,5(22)

H - 50 - 2,5

TUV-SV-97-525

Particle filter

24 - 30 kW: 4 x

G1 1/4 (internal

thread)

40 - 60 kW: 2 x

G1 1/4 (internal

thread), 2 x G2

(internal thread)

Non-return valves

24 - 30 kW: 4 x

G2 (internal

thread)

40 - 60 kW: 2 x

G2 (internal

thread)

Heat conducting

paste

3 x

Aluminium tape

1 x

LOCATION

The enclosed kit is placed in the packaging next to the

heat pump.

9Chapter 2 | Delivery and handlingNIBE F1345

Loading...

Loading...