Brine side

COLLECTOR

Caution

The length of the collector hose varies depend-

ing on the rock/soil conditions, climate zone

and on the climate system (radiators or under-

floor heating) and the heating requirement of

the building Each installation must be sized in-

dividually.

Max. length per coil for the collector should not exceed

500 m.

The collectors must always be connected in parallel with

the possibility of adjusting the flow for the relevant coil.

For surface soil heat, the hose should be buried at a

depth determined by local conditions and the distance

between the hoses should be at least 1 metre.

For several bore holes, the distance between the holes

must be determined according to local conditions.

Ensure the collector hose rises constantly towards the

heat pump to avoid air pockets. If this is not possible,

airvents should be used.

Because the temperature of the brine system may fall

below 0 °C, it must be protected against freezing down

to -15 °C. When making the volume calculation, 1 litres

of ready mixed brine per metre of collector hose (applies

when using PEM-hose 40x2.4 PN 6.3) is used as a guide

value.

Caution

Because the temperature of the brine system

varies depending on the heat source, the 5.1.7

“br pmp al set.” menu must be set to a suit-

able value.

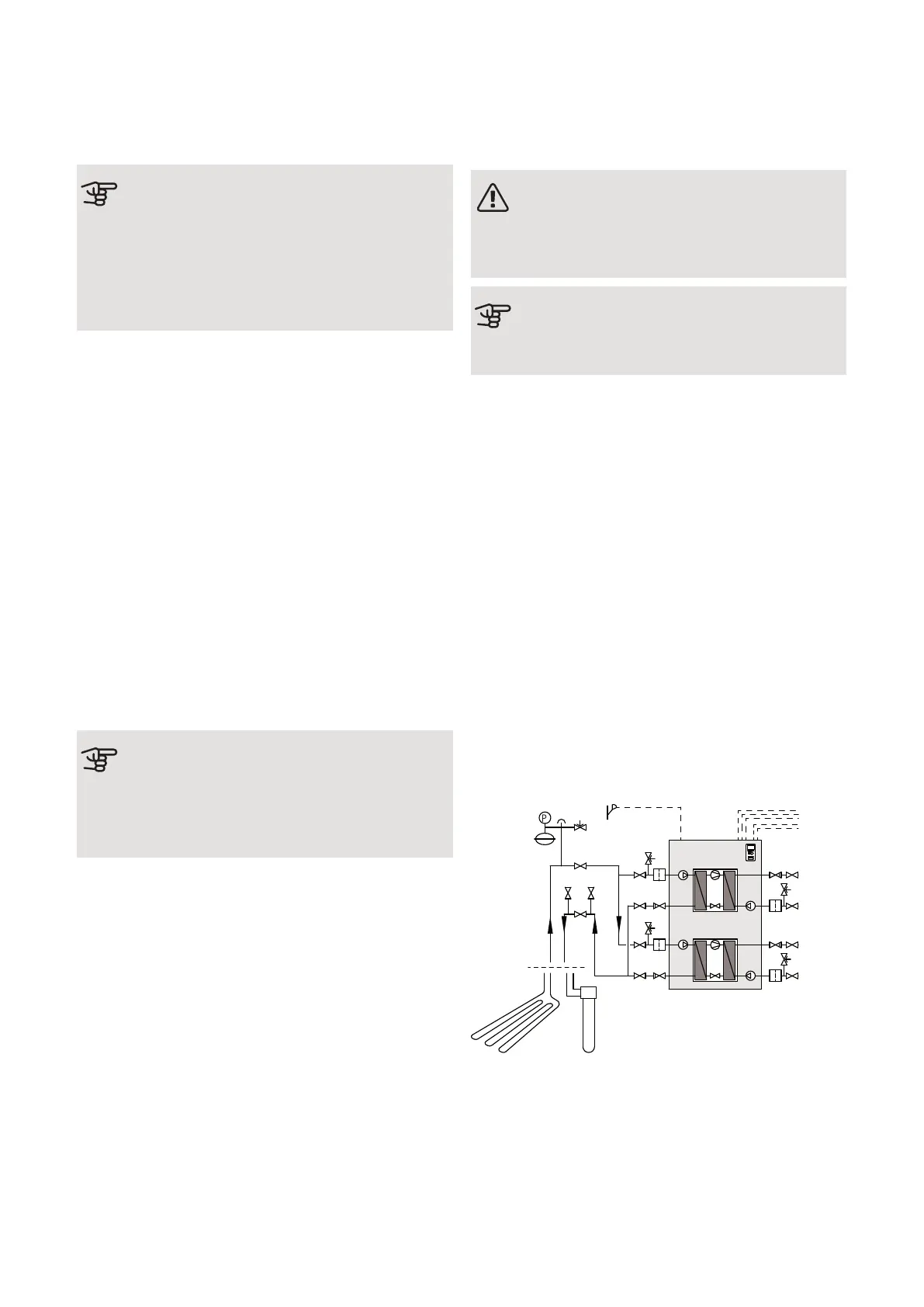

CONNECTING THE BRINE SIDE

• The pipe connections are on the rear of the heat pump.

• Insulate all indoor brine pipes against condensation.

NOTE

Condensation may drip from the expansion

vessel. Position the vessel so that this does

not harm other equipment.

Caution

When necessary you should install venting

valves in the brine system.

• Mark the brine system with the antifreeze that is used.

• Install the supplied safety valve at the expansion ves-

sel as illustrated in the outline diagram. The entire

length of the overflow water pipe from the safety

valves must be inclined to prevent water pockets and

must also be frost-free.

• Install shut off valves as close to the heat pump as

possible so that the flow to individual cooling modules

can be shut off. Extra safety valves between the

particle filter and shut off valves (according the outline

diagram) are required.

• Fit the supplied particle filter on the incoming pipe.

• Fit the supplied non-return valves on the outgoing

pipe.

In the case of connection to an open groundwater sys-

tem, an intermediate frost-protected circuit must be

provided, because of the risk of dirt and freezing in the

evaporator. This requires an extra heat exchanger.

NIBE F1345Chapter 4 | Pipe connections18

Loading...

Loading...