General information for the installer

9

For the Installer

FIGHTER 1220

Current regulations require the heating installation to

be inspected before it is commissioned. The inspec-

tion must be carried out by a suitably qualified person

and should be documented. The above applies to

closed heating systems. If the heat pump is replaced,

the installation must be inspected again.

FIGHTER 1220 is placed on a firm base, preferably a

concrete floor or foundation. Install FIGHTER 1220

with its back to an outside wall, ideally in a room

where noise does not matter. If this is not possible,

avoid placing it against a wall behind a bedroom or

other room where noise may be a problem. Irrespec-

tive of the placement the wall should be sound insulat-

ed. Route pipes so they are not fixed to an internal

wall that backs on to a bedroom or living room.

The FIGHTER 1220 must be transported and stored

upright and dry. The FIGHTER 1220 may however be

carefully laid on its back when being moved into a

building.

Transport and storage

Installation

Inspection of the installation

The unit can be used exclusively as an electric boiler,

to produce heat and hot water, for example before the

collector installation is complete. For this mode, the

hot water temperature is preset to 50 °C. See Set-

tings, menu 9.2.4.

The brine pump normally follows the operation of the

heat pump. There is a special operating mode for

continuous operation for 10 days, followed by return

to normal mode (this may be used before stable circu-

lation has been established). See Settings, menu.

9.2.12.

Electric boiler mode

FIGHTER 1220 is equipped with an electric anode to

protect the enamelled hot water heater. The electric

anode works automatically when FIGHTER 1220 is

switched on and is positioned behind the lower, ser-

vice cover.

■ A green LED on the transformer indicates that the

electric anode is operational.

■ When the LED is not lit the anode is not receiving

power; call the installer when this can not be recti-

fied.

■ When the LED flashes red, contact the installer.

Electric anode (enamel)

Brine pump

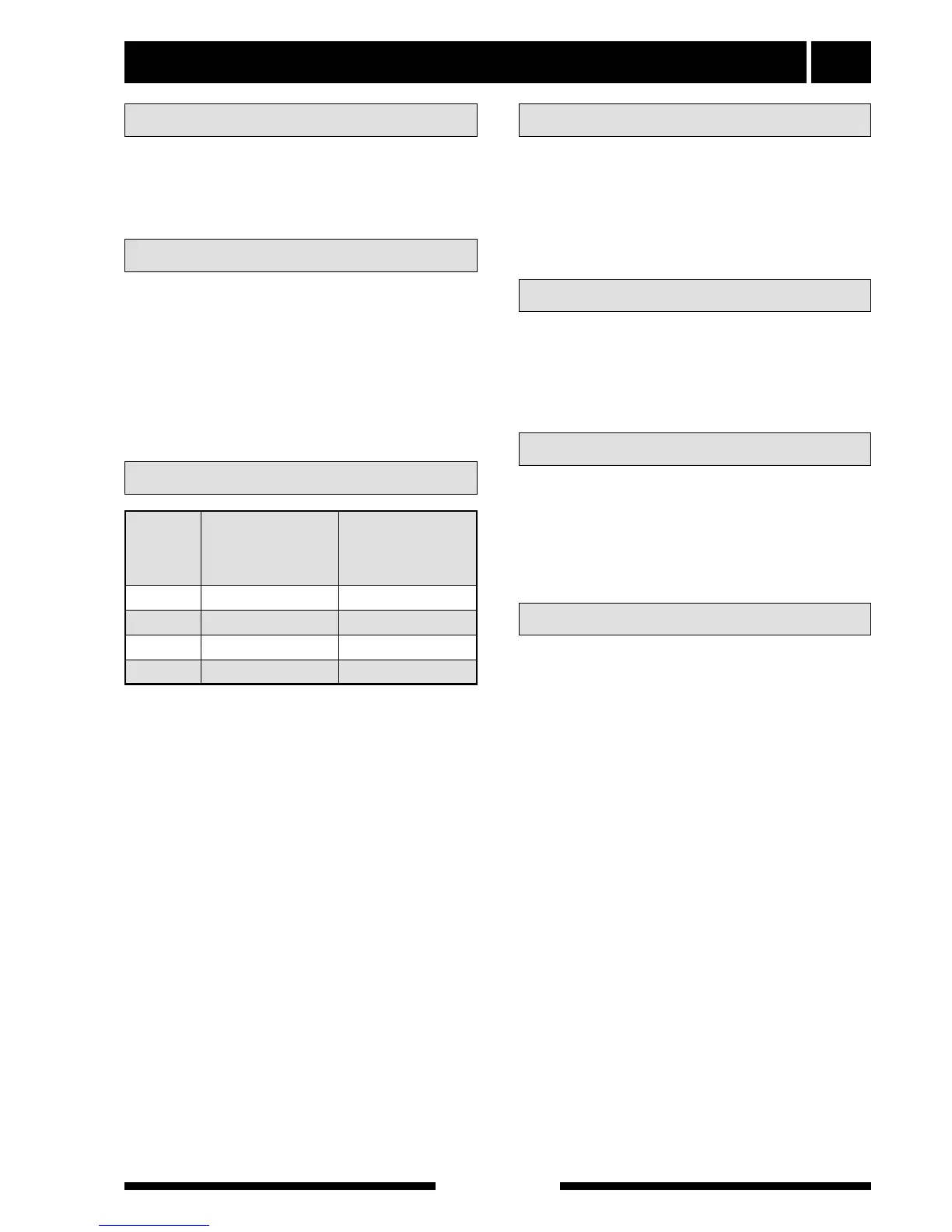

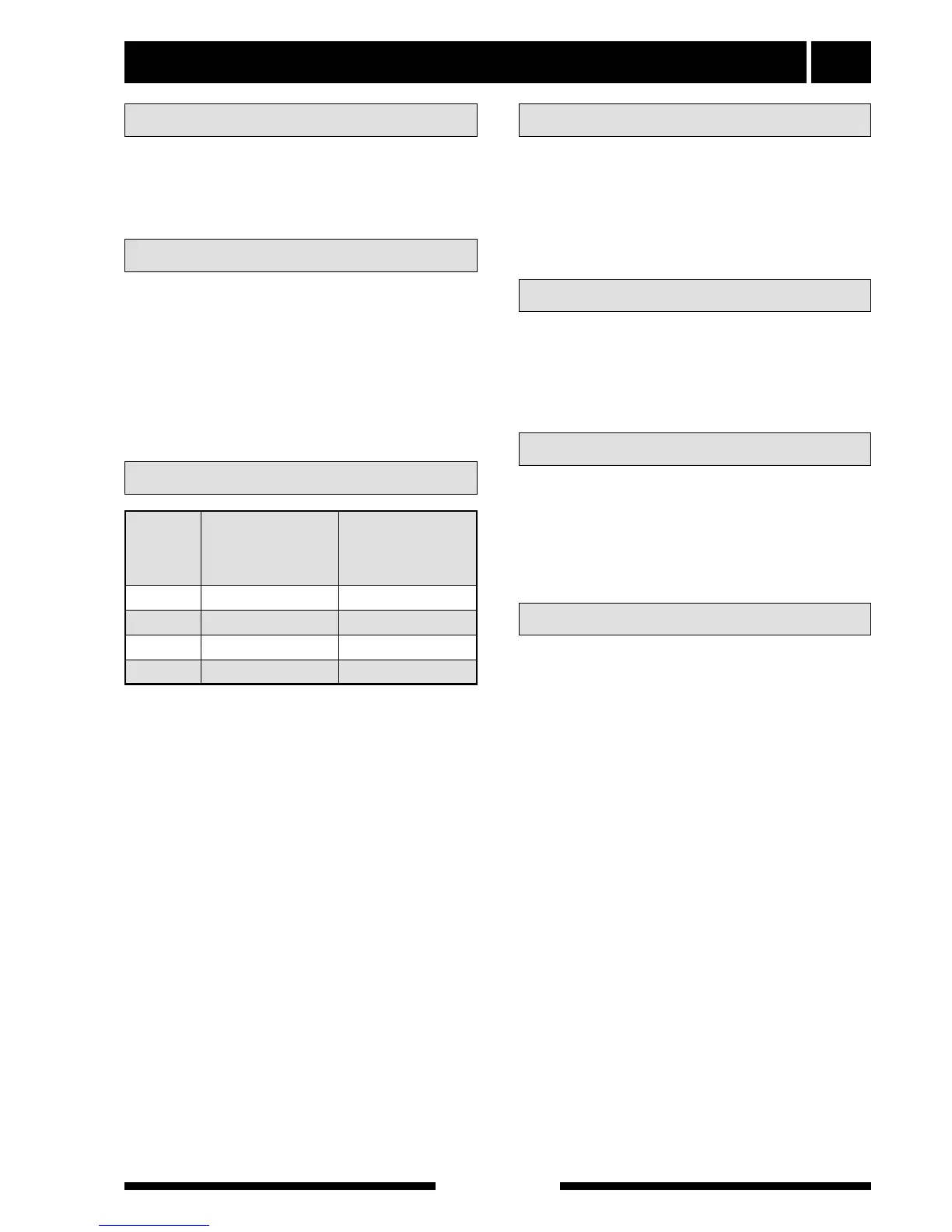

10 2x250 – 2x350 m 160 – 190 m

7 325 – 2x250 m 120 – 140 m)

Heat Surface soil heat, Rock heat,

pumps- recommended recommended

size collector length

active drilling depth

Guideline values for collectors

For use with 40 x 2.4 PN 6.3 PEM hose.

The length of the collector hose varies depending

on the rock /ground conditions and on the heating

system, i.e. radiators or floor heating.

Max length per collector should not exceed 400m.

Where there is more than one collector, they must be

connected in parallel, with a means of adjusting the

flow.

The hose should be buried at a depth of about 1 metre

and the distance between the hoses should be at least

1 metre.

For several bore holes, the distance between the

holes must be at least 15m.

5 250 – 400 m) 90 – 110 m)

8,5 400 – 2x300 m 140 – 170 m)

Loading...

Loading...