Digistart D3: User Guide 51

Issue: G

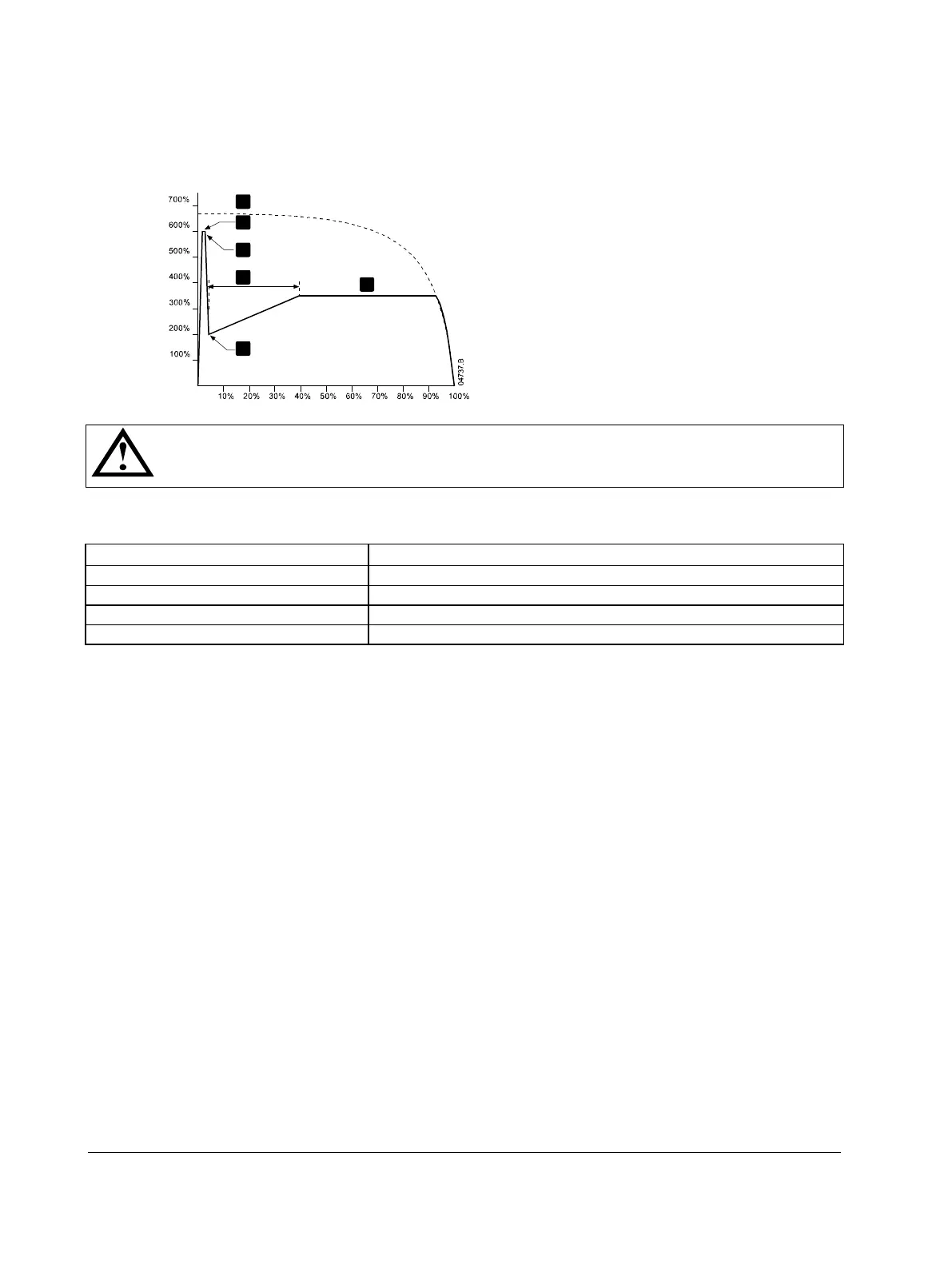

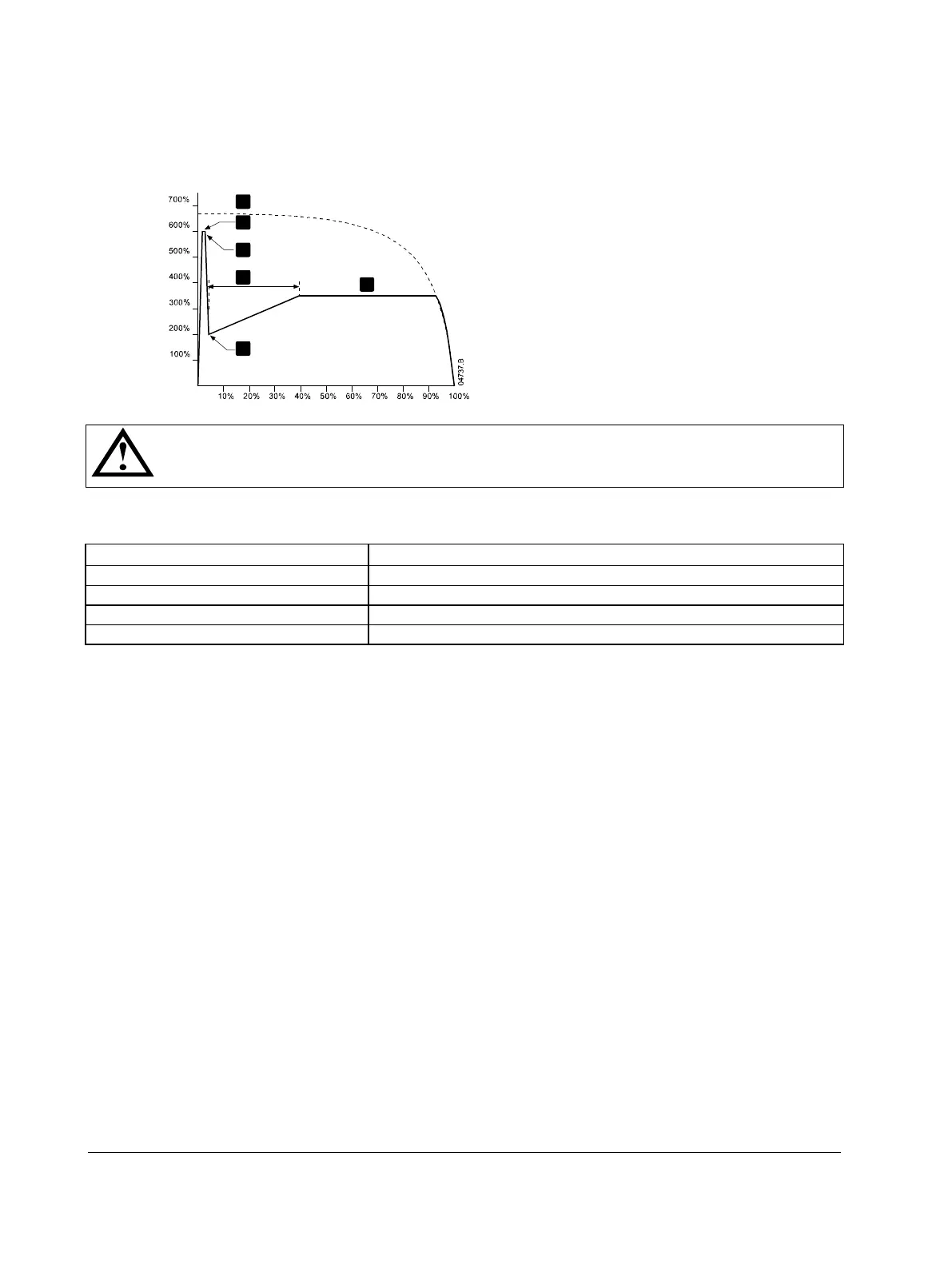

7.2.4 Kickstart

Kickstart provides a short boost of extra torque at the beginning of a start, and can be used in conjunction with

current ramp or constant current starting.

Kickstart can be useful to help start loads that require high breakaway torque but then accelerate easily (for example

helical rotor pumps).

Current

(%motor full load current)

1: Kickstart Level (Pr 2F)

2: Kickstart Time (Pr 2G)

3: Initial Current (Pr 2C)

4: Start Ramp Time (Pr 2D)

5: Current Limit (Pr 2B)

6: Full voltage current

Rotor speed (% full speed)

CAUTION

Kickstart subjects the mechanical equipment to increased torque levels. Ensure the motor, load and

couplings can handle the additional torque before using this feature.

7.3 Stop Methods

Soft starters offer a variety of methods for the control of motor stopping.

Extended run down time according to selected deceleration profile

Soft starters are often used in pumping applications to eliminate the damaging effects of fluid hammer. Adaptive

Control should be the preferred stop method for these applications.

To stop the motor, press the STOP button on the keypad or activate the Stop remote input. The motor will stop

using the stop mode selected in Pr 2H.

7.3.1 Coast to Stop

Coast to stop lets the motor slow at its natural rate, with no control from the soft starter. The time required to stop will

depend on the type of load.

Loading...

Loading...