60Service Manual – SC5000 04 - Control System

2-047 M7 Deck Act Mtr Overcurrent

Description

The power module has detected deck actuator motor current above 25 amps, which

exceeds the limitations of the power module.

Setting

Conditions

Same

When Monitored

Always

Possible Causes

• Failed actuator motor

• Short between the motor windings.

Initial Action None

Troubleshooting Steps

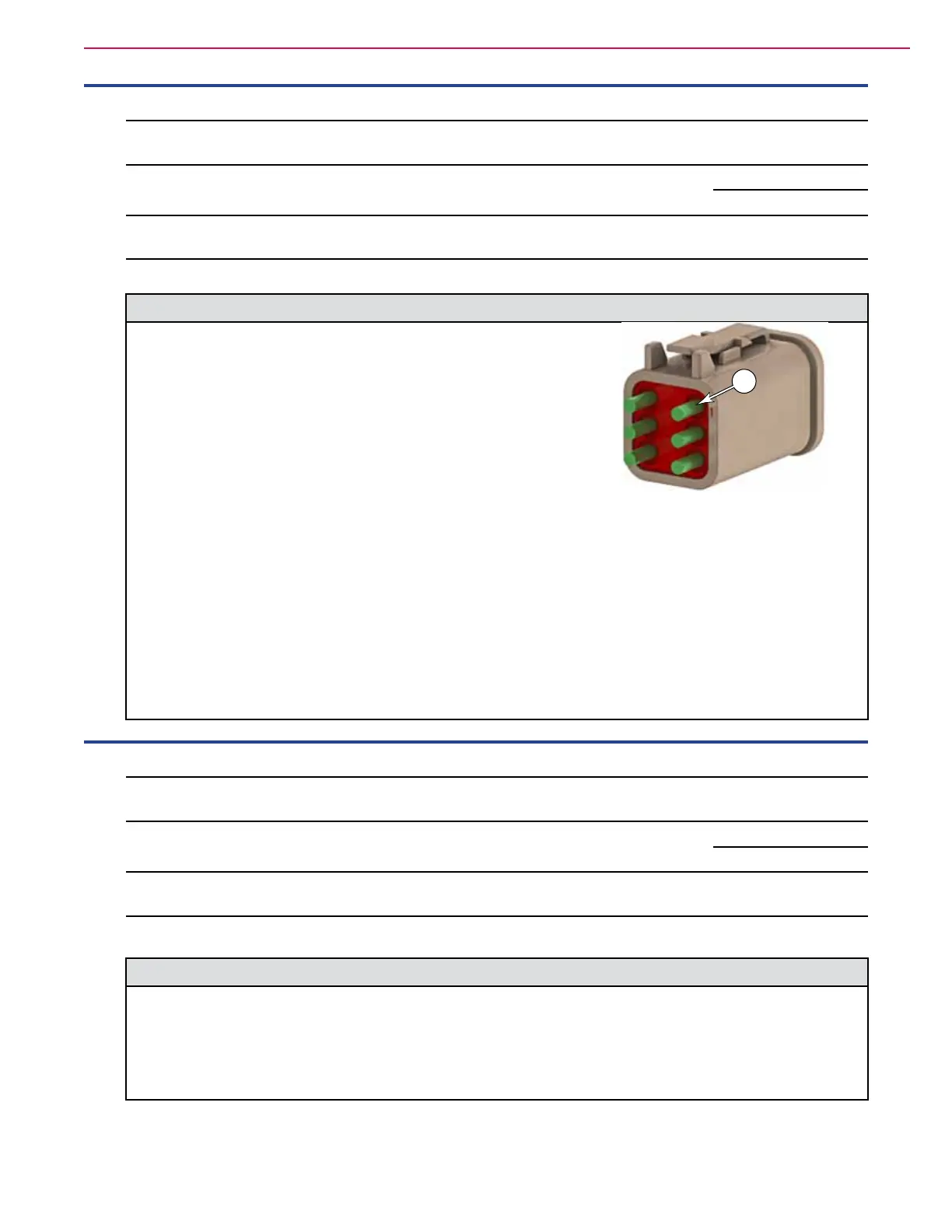

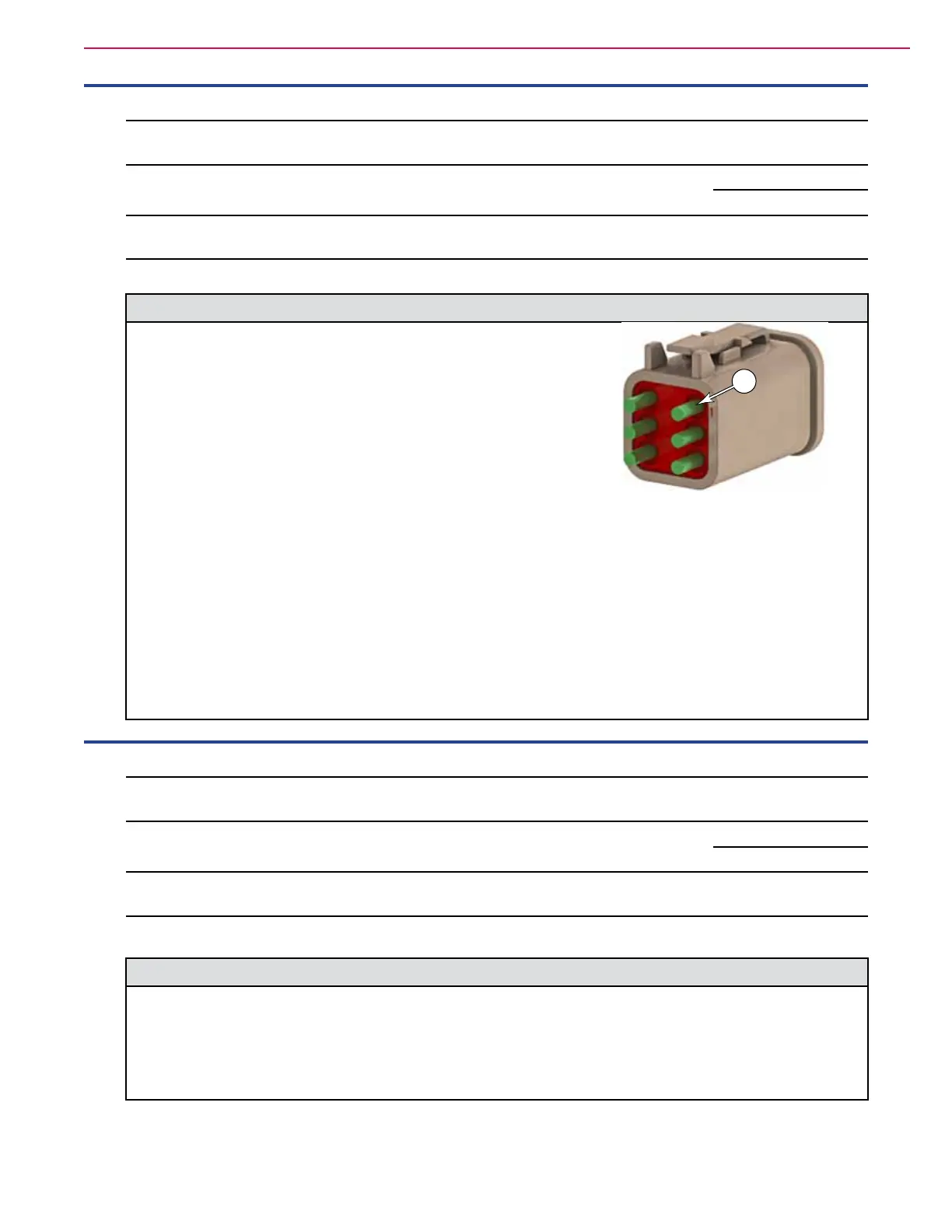

1. Measure the actuator motor resistance.

a. Disconnect the deck actuator connector.

b. Measure the resistance between contacts 1 and 2 of the

actuator connector.

• Make sure to check resistance in both forward and reverse

polarity, in case the actuator is stopped at a limit switch.

– If the resistance is less than 250 ohms, replace the actuator.

– If the resistance is greater than 250 ohms, continue.

2. Test the harness.

a. With the actuator still disconnected, power up the machine with Service mode access.

b. Navigate to the Output Test menu and command the M7 Deck Actuator to operate in one direction,

and then the other. Clear any errors as necessary to continue.

– If the motor overcurrent error occurs in both directions of travel, the motor wires (BLU/GRY &

ORN/GRY) are shorted to one another.

– If the error occurs in the UP direction but not the DN direction, either BLU/GRY shorted to

B-negative, or ORN/GRY shorted to B-positive.

– If the error occurs in the DN direction but not the UP direction, either BLU/GRY shorted to

B-positive, or ORN/GRY shorted to B-negative.

• Repair or replace the harness as appropriate.

2-048 M8 Option Pump Motor Overcurrent

Description

The power module has detected wash pump motor current above 25 amps, which

exceeds the limitations of the power module.

Setting

Conditions

Same

When Monitored

Always

Possible Causes

Because the overcurrent condition has reached the maximum permissible amperage

of the power module, it is likely that the motor or control wiring is shorted.

Initial Action None

Troubleshooting Steps

1. Disconnect the motor connector.

2. Check the resistance between the contacts on the harness leading back toward the power module.

− If the resistance is at or near 0 ohms, repair or replace the harness.

− If the resistance is not near 0 ohms, replace the motor.

1

Loading...

Loading...