Wheel System, Traction 196Service Manual – SC6500

™

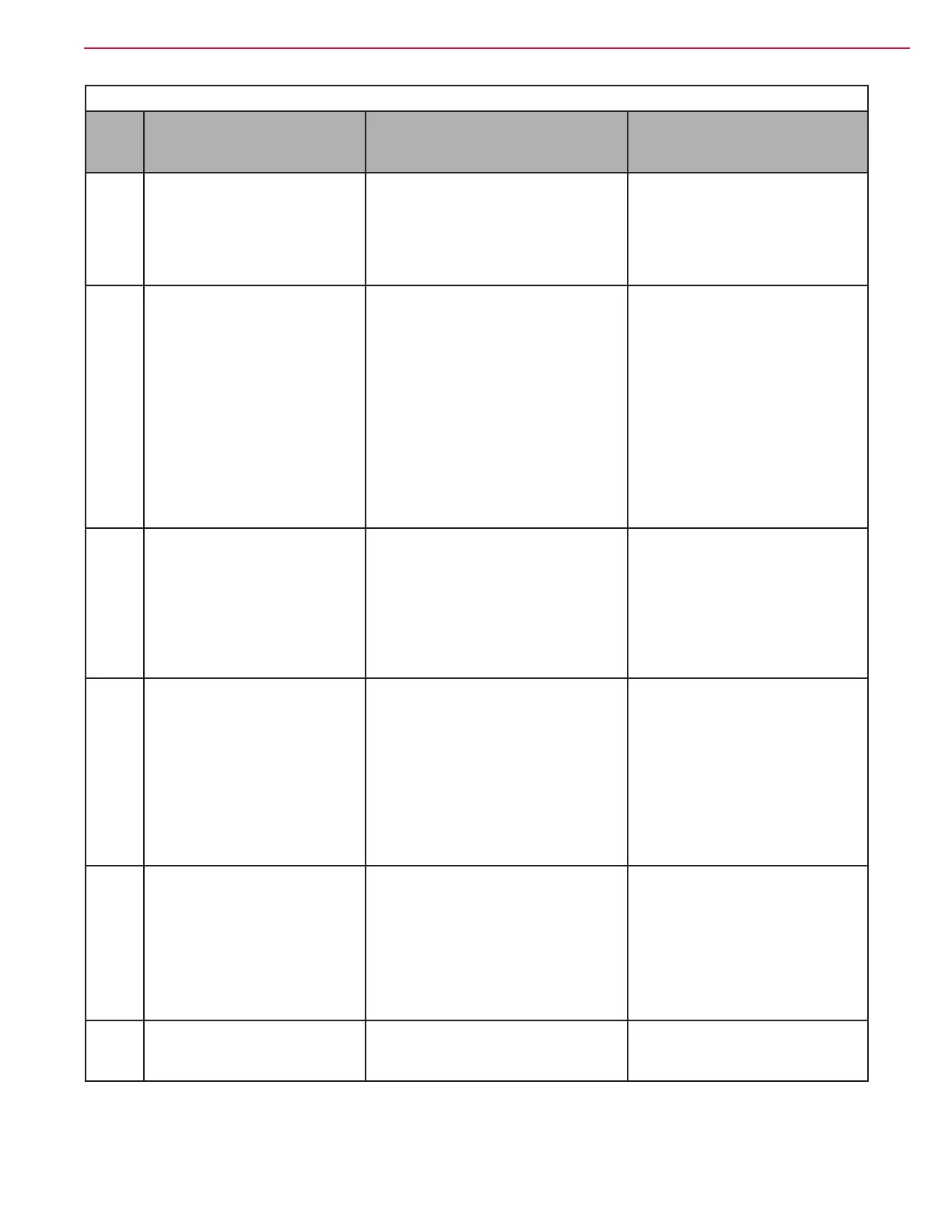

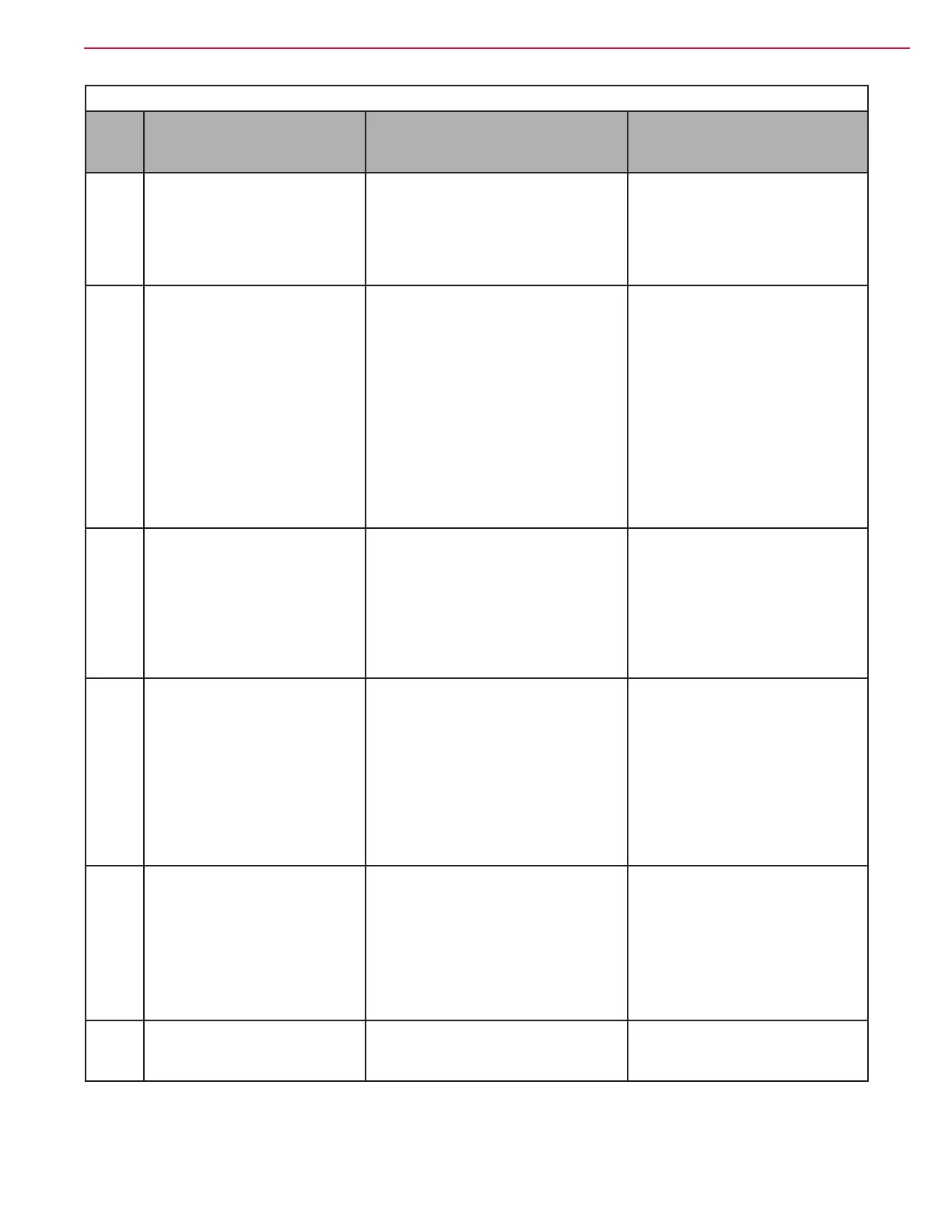

Troubleshooting Chart

Flash

Code

#

Programmer LCD

Display/ Effect Of Fault

Possible Cause(s) Set/Clear Conditions

45 Pot Low Overcurrent

ShutdownThrottle;

FullBrake.

1. See Monitor menu » Outputs:

Pot Low.

2. Combined pot resistance

connected to pot low is too low.

Set: Pot low (pin 18) current

exceeds 10mA.

Clear: Clear pot low

overcurrent condition and cycle

KSI.

46 EEPROM Failure

ShutdownMotor;

ShutdownMainContactor;

ShutdownEMBrake;

ShutdownThrottle;

ShutdownInterlock;

ShutdownDriver1;

ShutdownDriver2;

ShutdownDriver3;

ShutdownDriver4;

ShutdownPD; FullBrake;

ShutdownPump.

1. Failure to write to EEPROM

memory. This can be caused

by EEPROM memory writes

initiated by VCL (Vehicle

Control Language), by the

CAN Bus, by adjusting

parameters with the

programmer, or by loading new

software into the controller.

Set: Controller operating

system tried to write to

EEPROM memory and failed.

Clear: Download the correct

software (OS) and matching

parameter default settings into

the controller and cycle KSI.

47 HPD/Sequencing Fault

ShutdownThrottle.

1. KSI, interlock, direction, and

throttle inputs applied in

incorrect sequence.

2. Faulty wiring, crimps, or

switches at KSI, interlock,

direction, or throttle inputs.

3. See Monitor menu » Inputs.

Set: HPD (High Pedal Disable)

or sequencing fault caused

by incorrect sequence of KSI,

interlock, direction, and

throttle inputs.

Clear: Reapply inputs in

correct sequence.

47 Emer Rev HPD

ShutdownThrottle;

ShutdownEMBrake.

1. Emergency Reverse operation

has concluded, but the throttle,

forward and reverse inputs,

and interlock have not been

returned to neutral.

Set: At the conclusion of

Emergency Reverse, the fault

was set because various inputs

were not returned to neutral.

Clear: If EMR_Interlock = On,

clear the interlock, throttle,

and direction inputs. If

EMR_Interlock = Off, clear the

throttle and direction inputs.

49 Parameter Change Fault

ShutdownMotor;

ShutdownMainContactor;

ShutdownEMBrake;

ShutdownThrottle;

FullBrake; ShutdownPump.

1. This is a safety fault caused by

a change in certain parameter

settings so that the vehicle will

not operate until KSI is cycled.

For example, if a user changes

the Throttle Type this fault will

appear and require cycling KSI

before the vehicle can operate.

Set: Adjustment of a parameter

setting that requires cycling of

KSI.

Clear: Cycle KSI.

51 -

67

OEM Faults

1. These faults can be dened by

the OEM, These faults are not

used on the SC6500

Set: Not Applicable.

Clear: Not Applicable.

Loading...

Loading...