44292401TH Rev.1

127 /

Oki Data CONFIDENTIAL

ADJUSTMENT/SETTING

Function

• To adjust for variations in the accuracy of all parts and their mounting accuracy by vary-

ing the scanning start position in the main scanning direction (1-side) when using the

Automatic Document Feeder.

Use

• When the MFP board has been replaced.

• When the original glass is replaced.

• When a new Auto Document Feeder Unit is mounted

NOTE

• When the MFP board is replaced, the setting value is cleared. Re-entering a new

setting value is necessary.

• After the [CIS SUB ZOOM] adjustments have been performed

• After the [ADF SUB ZOOM] adjustments have been performed

Adjustment

Specifica-

tion

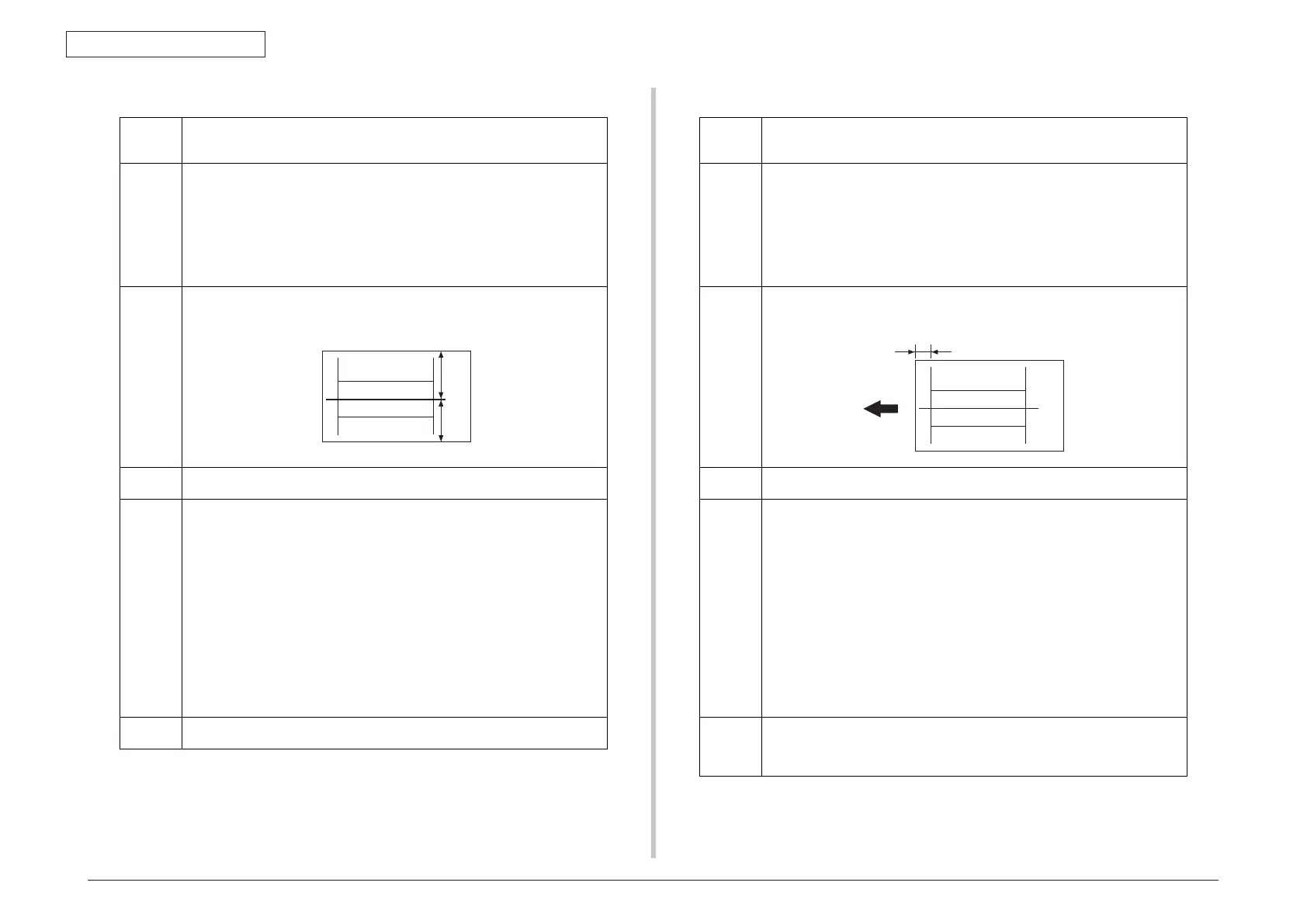

• Adjust the amount that widths A and B in the copy of the test pattern1 so that the follow-

ing specification is met.

• 0 ± 2.0 mm

Adjustment

Range

• -5.0 (-5.0 mm) ~ “0.0 (0.0 mm)” ~ +5.0 (+5.0 mm)

• Step: 0.5 mm

Setting/

Procedure

1. Print the test pattern1.

See P.131

2. Enter the [ADJUST] menu in the service mode.

3. Select [ADF MAIN REG], and press the Select key.

4. Place test pattern 1 in the ADF with its printed surface up.

5. Select [TEST COPY] and press the Select key to make a test copy.

NOTE

• The test pattern1 should be positioned vertically.

• Use A4 or Letter paper loaded into tray1 to make the test copy.

6. Check the amount that widths A and B in the copy of the test pattern are shifted.

If the shift is out of specification, adjust it according to the following procedure.

7. Select [ADJUST], and press the Select key.

8. Using the S/T key, change the setting value and then press the Select key.

9. Place the test pattern1 into the Automatic Document Feeder. Then, make a test copy

again and check it.

Adjustment

Instructions

• If the width of A is less than the width of B..... Increase the setting.

• If the width of B is less than the width of A..... Decrease the setting.

4139F3C546DA

A

B

Function

• To adjust for variations in the accuracy of all parts and their mounting accuracy by vary-

ing the scanning start position in the sub-scanning direction (1-side) when using the

Automatic Document Feeder.

Use

• When the MFP board has been replaced.

• When the original glass is replaced.

• When a new Auto Document Feeder Unit is mounted

NOTE

• When the MFP board is replaced, the setting value is cleared. Re-entering a new

setting value is necessary.

• After the [CIS SUB ZOOM] adjustments have been performed

• After the [ADF SUB ZOOM] adjustments have been performed

Adjustment

Specifica-

tion

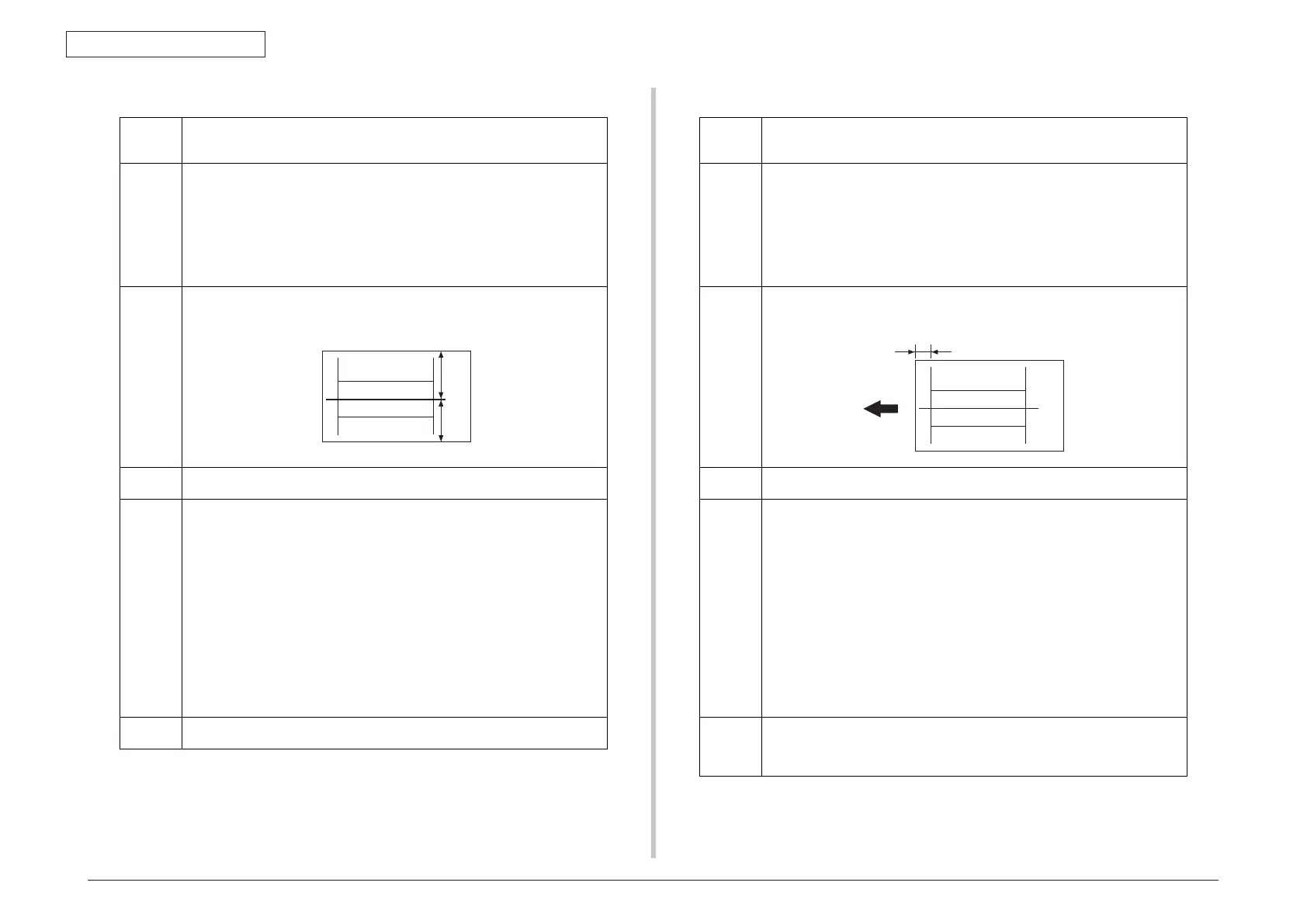

• Adjust the width of C in the copy of the test pattern1 so that the following specification is

met.

• 20 ± 2.5 mm

Adjustment

Range

• -5.0 (-5.0 mm) ~ “0 (0 mm)” ~ +5.0 (+5.0 mm)

• Step: 0.5 mm

Setting/

Procedure

1. Print the test pattern1.

See P.131

2. Enter the [ADJUST] menu in the service mode.

3. Select [ADF SUB REG], and press the Select key.

4. Place test pattern 1 in the ADF with its printed surface up.

5. Select [TEST COPY] and press the Select key to make a test copy.

NOTE

• The test pattern1 should be positioned vertically.

• Use A4 or Letter paper loaded into tray1 to make the test copy.

6. Check that the width of C in the copy of the test pattern are shifted.

If the width of C is out of specification, adjust it according to the following procedure.

7. Select [ADJUST], and press the Select key.

8. Using the S/T key, change the setting value and then press the Select key.

9. Place the test pattern1 into the Automatic Document Feeder. Then, make a test copy

again and check it.

Adjustment

Instructions

• If the width of C in the test pattern is longer than the specified width

..... Increase the setting.

• If the width of C in the test pattern is shorter than the specified width

..... Decrease the setting.

4139F3C547DA

C

13.4.7 ADF SUB REG13.4.6 ADF MAIN REG

Loading...

Loading...