6-34

WARNING

Many troubleshooting procedures present hazards that can result in severe personal inju-

ry or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery haz-

ards should perform service procedures. Review safety precautions on page iii.

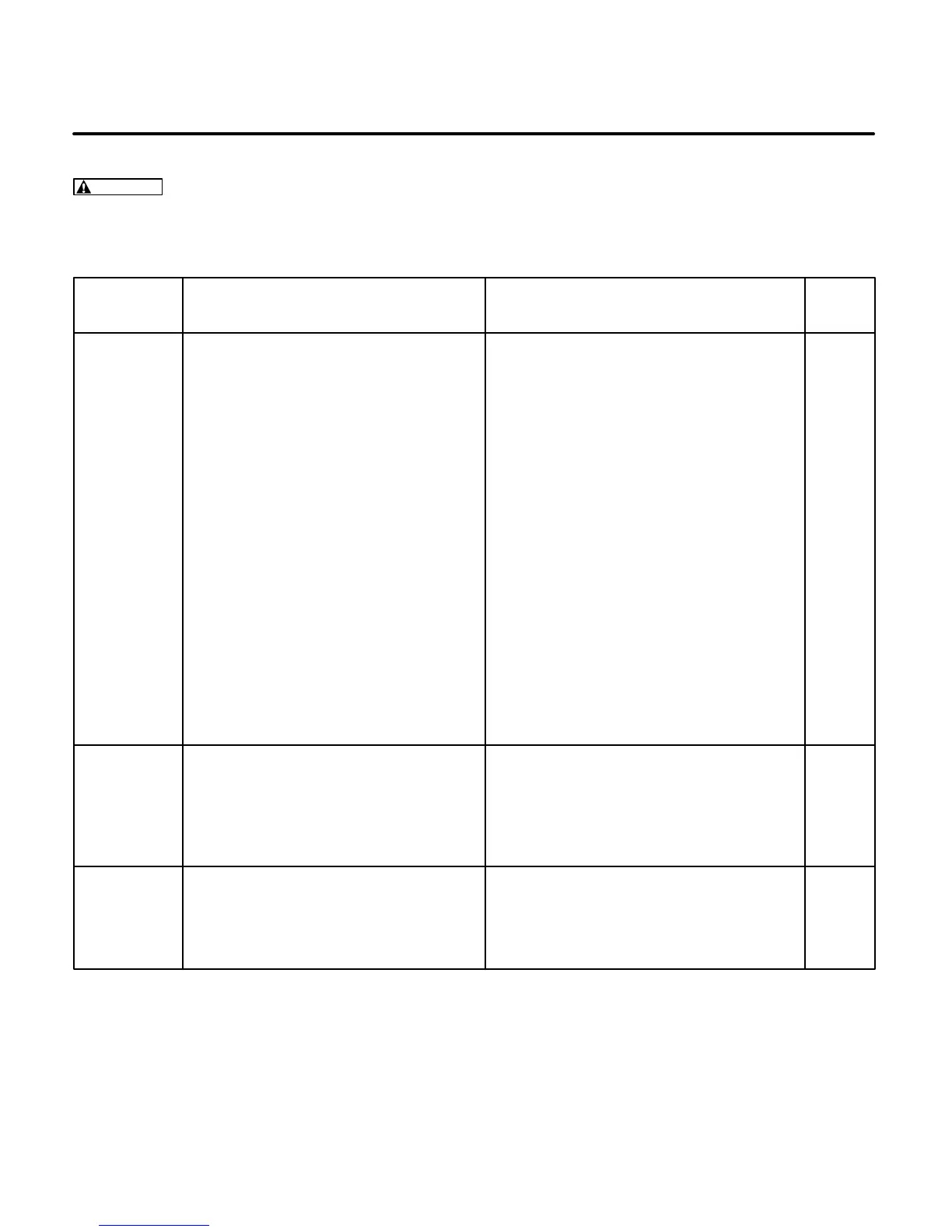

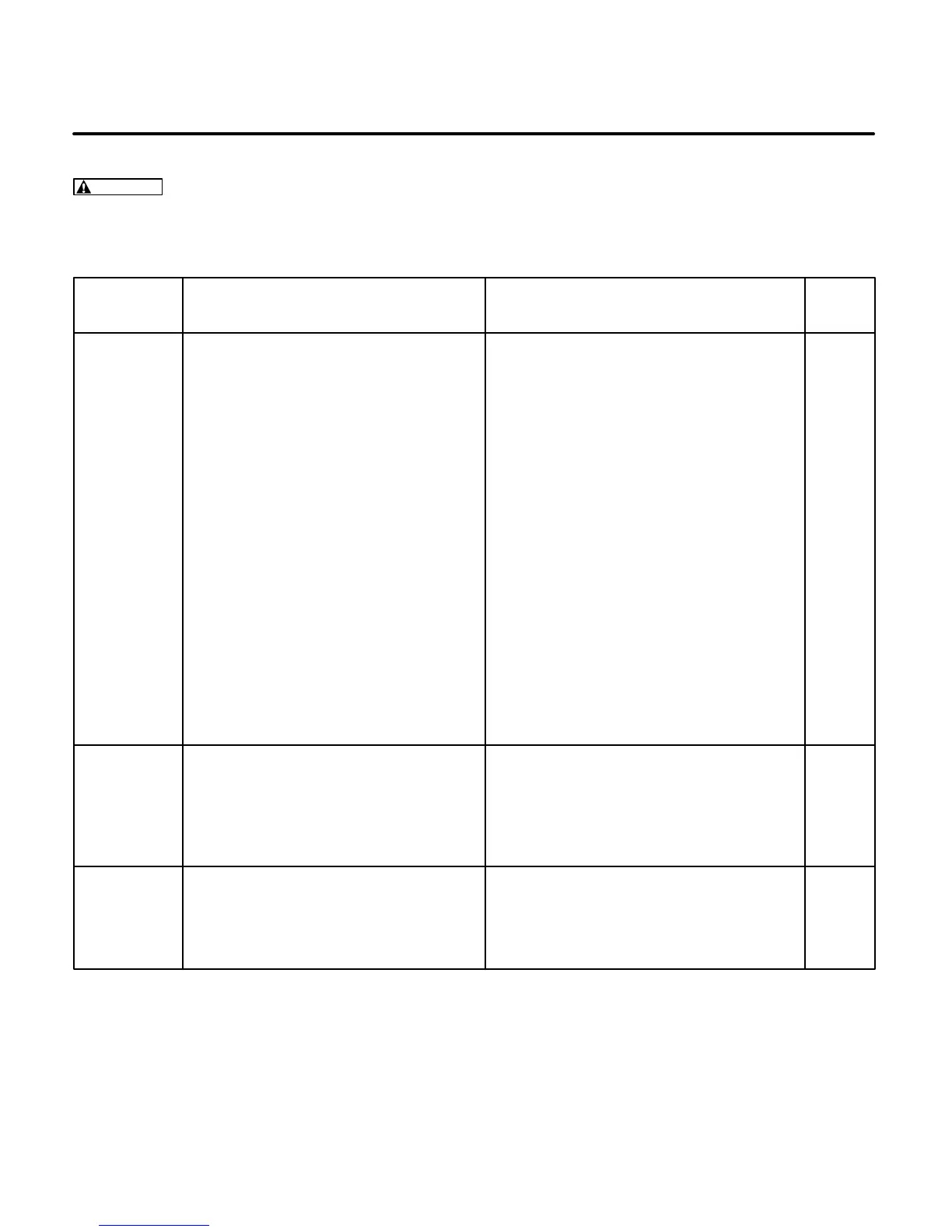

TABLE 6-17. TROUBLESHOOTING ENGINE PRIMARY SYSTEMS

Trouble Possible Cause Corrective Action Section/

Page

Engine 1. Restricted airflow due to dirt, debris 1. Clear air inlet and outlet areas. Do not

Overheats or insulation blocking air inlet or outlet. store anything in compartment area.

2. Dirt or oil on engine cooling fins. 2. Clean all dirt and oil from engine

cooling fins.

3. mCooling fan plugged or broken. 3. Inspect cooling fan, clean or replace

as needed,

4. Lean fuel mixture due to:

a. Incorrectly adjusted fuel 4a. Adjust carburetor main and idle 8-14

mixture screws. adjustment screws.

b. Dirt or varnish in carburetor. 4b. Disassemble carburetor and clean 8-15

all internal passages.

5. Loose or missing service access cover 5. Check for proper fit of service access

or improper seal around the endbell cover and check seal around endbell.

assembly.

6. Improper installation due to:

a. Insufficient air inlet size. 6a. Make sure air inlet is not blocked and

b. Air inlet location allowing that it is properly sized (refer to

recirculation. Installation Manual).

6b. Make sure that air outlet is not blocked

and check for recirculation of outlet air.

Black Exhaust 1. Rich fuel mixture due to: 1a. Replace air filter. 8-11

Smoke a. Dirty air filter. 1b. Clean choke and choke linkage.

b. Choke sticking. 1c. Adjust carburetor idle and main 8-14

c. Incorrectly adjusted fuel mixture adjustment screws.

screws. 1d. Disassemble carburetor and clean all 8-15

d. Dirt or varnish in carburetor. internal passages.

White or Blue 1. Oil level too high. 1. Lower oil level.

Exhaust

Smoke 2. Contaminated fuel. 2. Drain and refill fuel tank.

3. Excessive engine wear. 3. Perform Leak Down Test. 10-1

Loading...

Loading...